Heavy-duty workpiece translation device

A technology of translation device and workpiece, which is applied in the directions of transportation, packaging, runners, etc., can solve the problems of unsatisfactory effect, damage to the work surface, time-consuming and labor-intensive, etc., and achieves the effect of simple structure, remarkable effect, practical and convenient effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below through the description of specific embodiments with reference to the accompanying drawings.

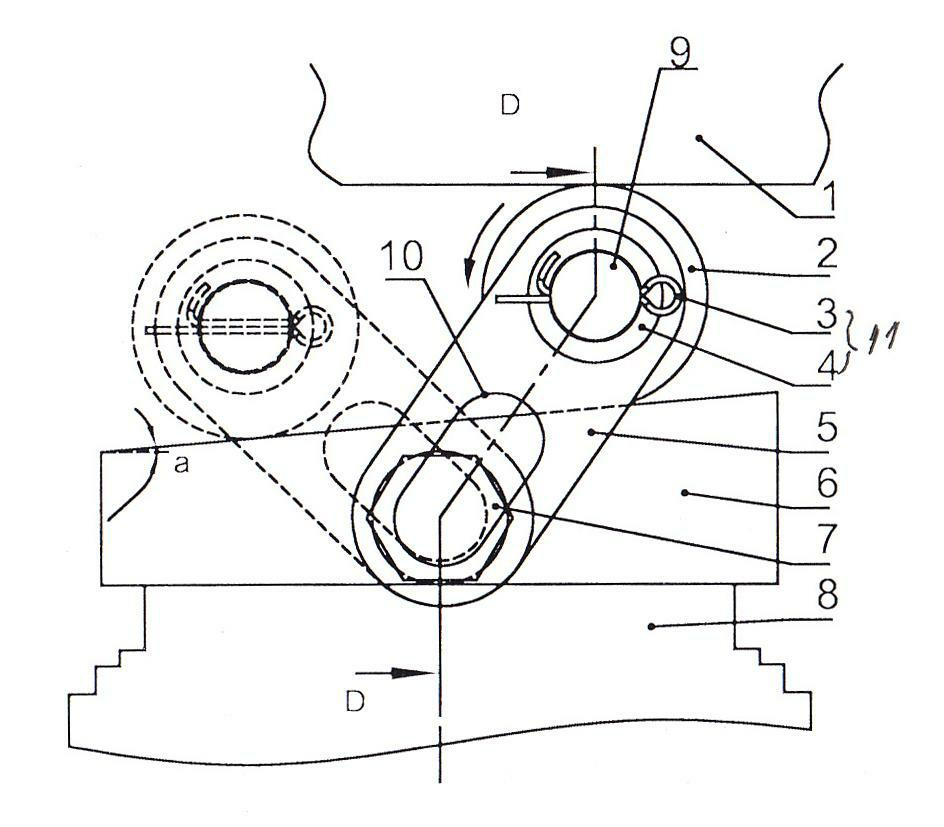

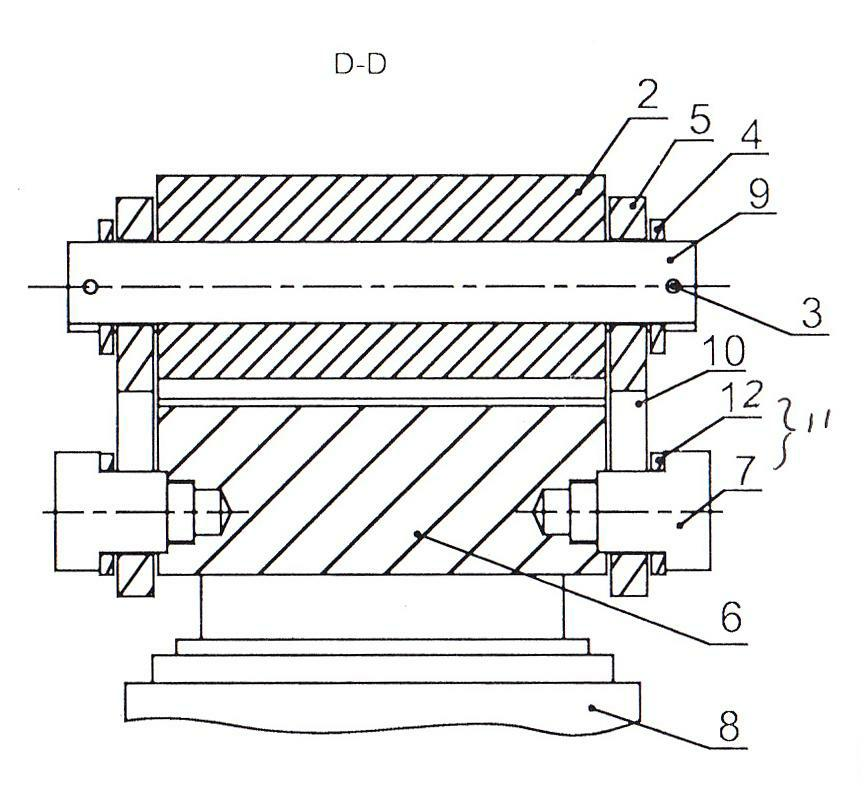

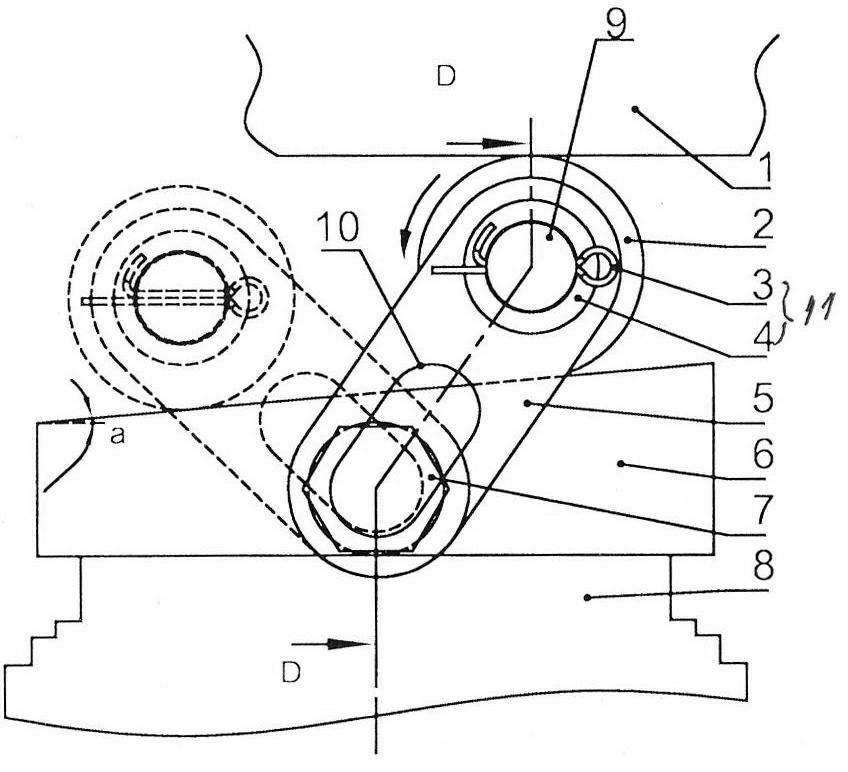

[0017] Specific implementation, as attached figure 1 , 2 shown.

[0018] A heavy-duty workpiece translation device, comprising a jack 8, a wedge 6, a sliding roller 2, and left and right symmetrically arranged swinging members 5; one end of the left and right swinging member 5 is movably matched with the sliding roller 2 shaft 9 in a shaft hole, The other ends of the left and right oscillating members 5 pass through the oblong holes 10 provided therein, and the pins 7 fixedly connected with the wedge block 6 are in axial hole clearance fit; The part 5 moves outward along the axial direction and falls off the anti-off member 11; the top of the jack 8 can abut against the bottom plane of the wedge block 6; 9 and the first washer 4 located on the outside of the swing member 5, and the cotter pin 3 arranged on the shaft 9 of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com