Plant fiber-based polylol and preparation method thereof

A plant fiber and polyol technology, applied in the field of polymer chemistry, can solve the problems of unsatisfactory and inactivation, and achieve the effect of high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

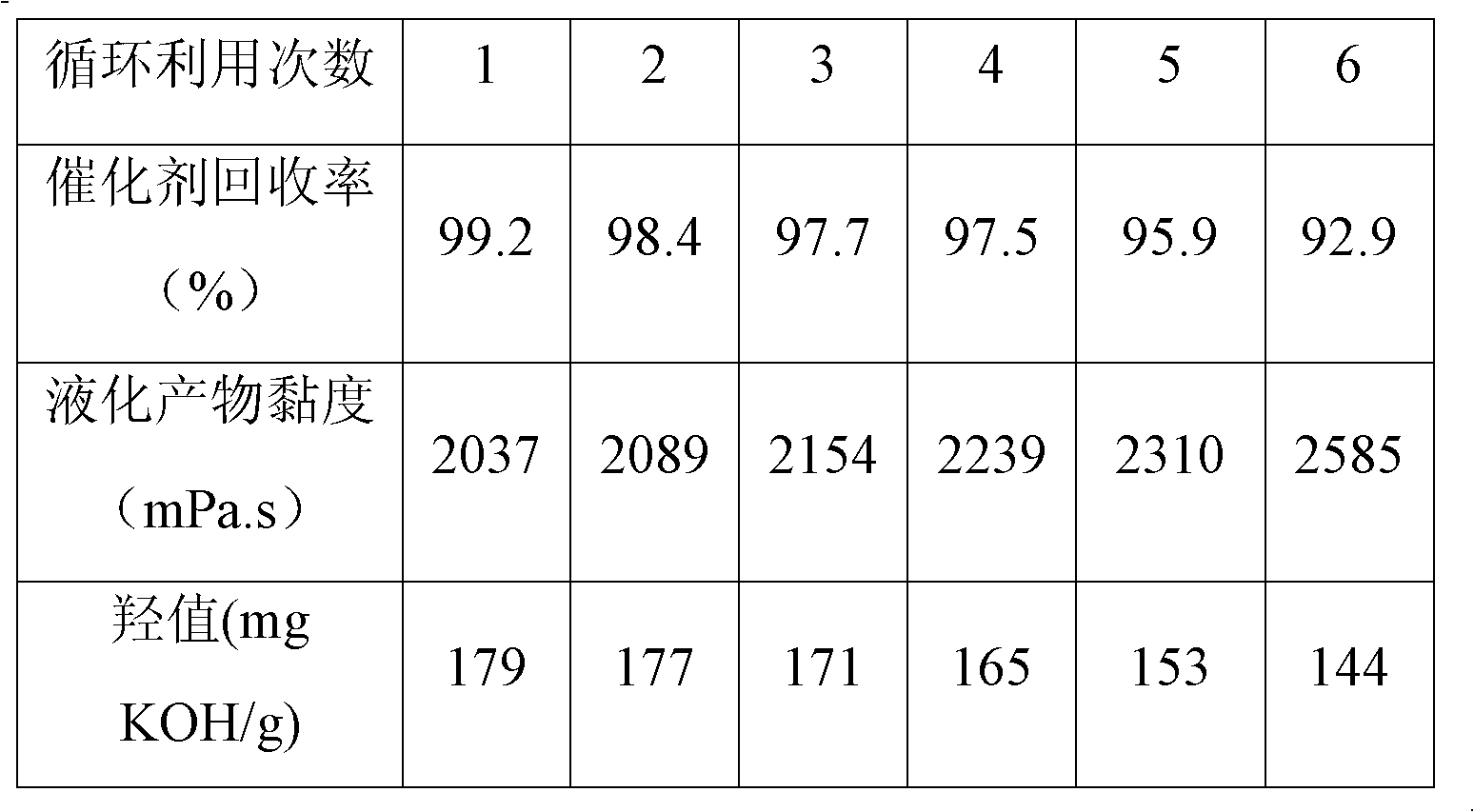

Embodiment 1

[0035] (1) Preparation of catalyst: Dissolve 10g of phosphotungstic acid in 20g of deionized water, then add 10g of SiO 2 After standing for 5 hours, dry at 100°C, place in a muffle furnace, and roast at 250°C for 5 hours to obtain the required solid heteropolyacid catalyst; (2) liquefaction of plant fiber raw materials: Mix the liquefaction reagent consisting of 5g of polyethylene glycol 200 and 5g of ethylene glycol, 0.01g of the solid heteropolyacid obtained in step (1) and 10g of dry 20-60 mesh corn cob powder raw materials evenly, and heat the mixture to 100°C , then evacuate to 0.1MPa (negative pressure), keep warm for 150min, and then discharge, the product obtained is centrifuged at a speed of 1000r / min with a centrifuge, the liquid product is plant polyol, and the solid is liquefied residue and solid heteropoly Acid catalyst; (3) Regeneration of solid heteropolyacid: the solid heteropolyacid recovered in step (2) was removed in an oven to remove moisture, then washed ...

Embodiment 2

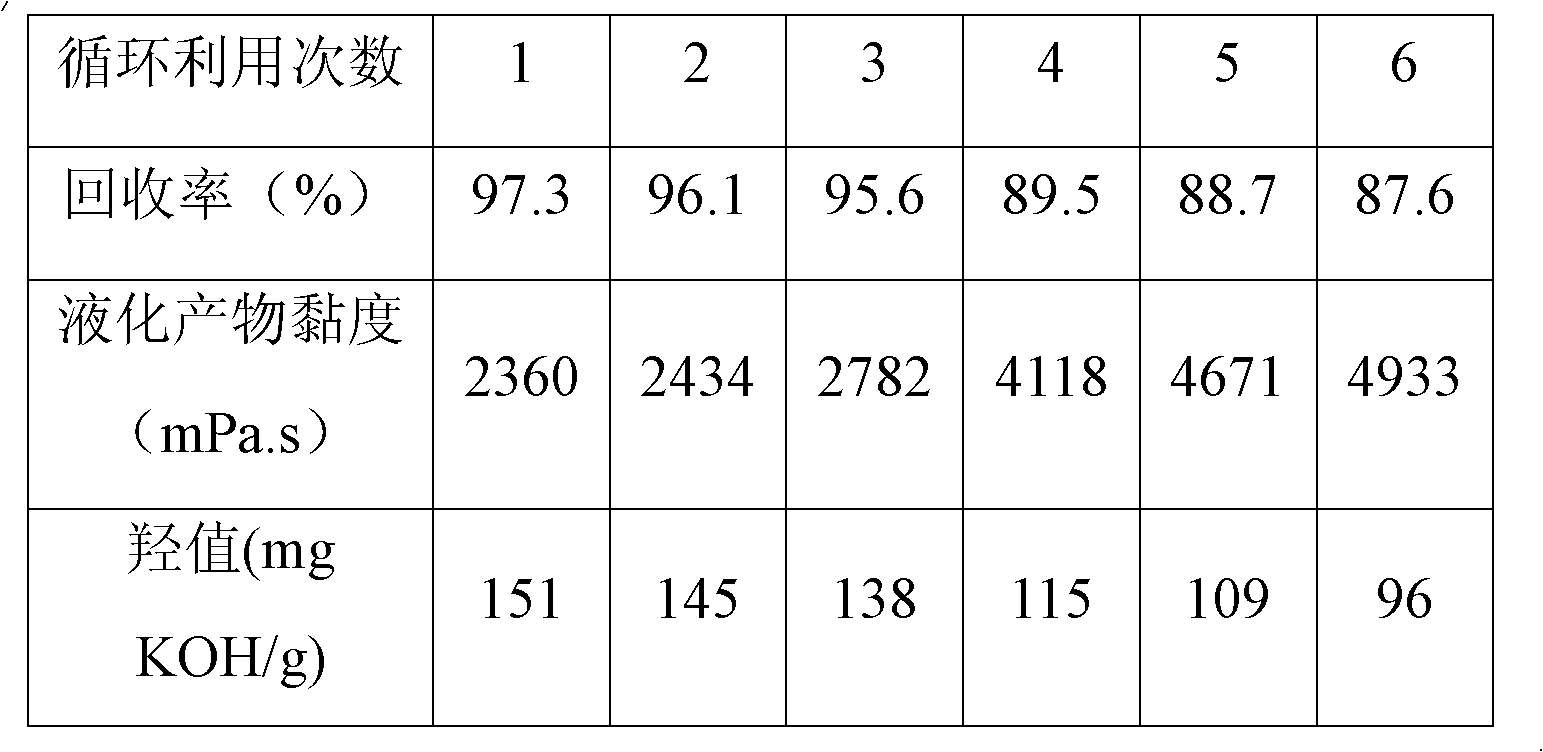

[0037] (1) Preparation of catalyst: Dissolve 10g of silicotungstic acid in 20g of deionized water, then add 10g of activated carbon, let it stand for 20 hours, dry it at 90°C, and then place it in a muffle furnace, in an air-isolated environment Under conditions, roasting 2 hours at 400 ℃ of temperature, obtain required solid heteropolyacid catalyst; (2) liquefaction of plant fiber raw material: 40g Polyethylene Glycol 200, 9.5g Polyethylene Glycol 800 and 0.5g Propylene Glycol The liquefied reagent, 0.1g of the solid heteropolyacid obtained in step (1) and 10g of dry 160-200 mesh corn stalk powder raw materials are mixed evenly, and the mixture is heated to 150°C, and then vacuumed to 0.5MPa (negative pressure) , while insulated for 100min, then discharging, the product obtained is centrifuged at 3000r / min rotating speed with a centrifuge, the liquid product is a plant polyol, and the solid is a liquefaction residue and a solid heteropolyacid catalyst; (3) solid heteropolyacid...

Embodiment 3

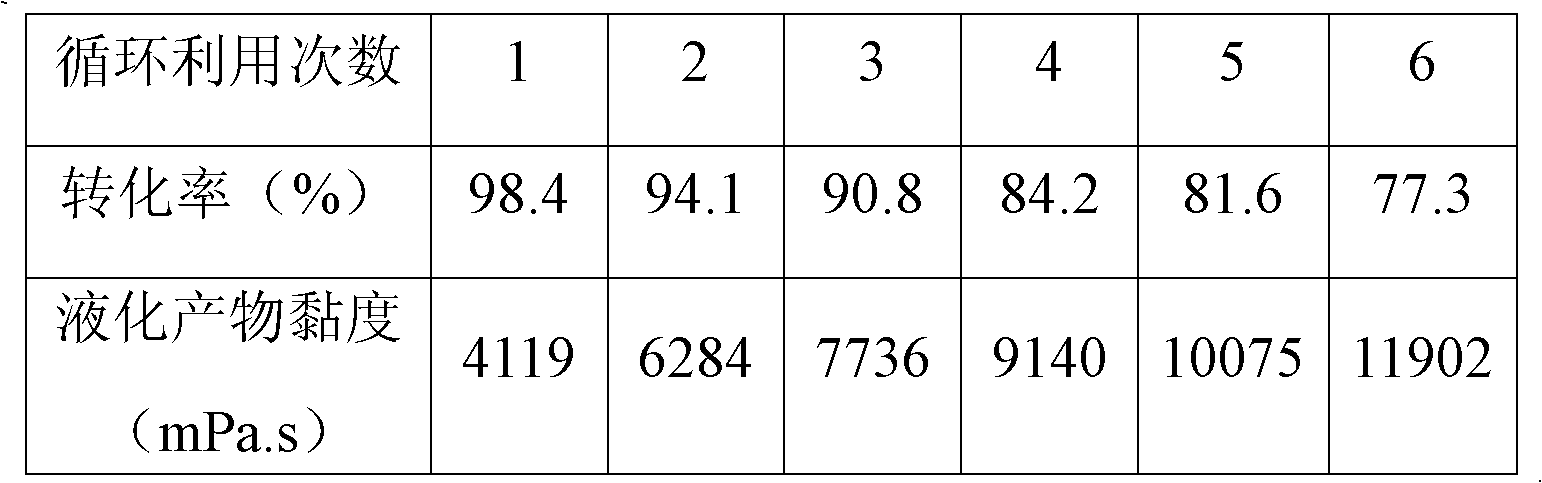

[0039] (1) Preparation of catalyst: Dissolve 10 g of phosphomolybdenum heteropoly acid in 20 g of deionized water, then add 10 g of macroporous MCM-41 molecular sieve, leave it for 15 hours, dry at 95°C, and place In the muffle furnace, roast at 300°C for 4 hours to obtain the required solid heteropolyacid catalyst; (2) liquefaction of plant fiber raw materials: the liquefaction reagent composed of 25g polyethylene glycol 400 and 5g glycerol, 0.45g Mix the solid heteropolyacid obtained in step (1) and 10 g of dry reed powder raw materials of 60-100 mesh evenly, heat the mixture to 140°C, then vacuumize to 0.5MPa (negative pressure), keep it warm for 30min, and then discharge , the product that obtains is centrifuged at 3500r / min rotating speed with centrifuge, and liquid product is plant polyol, and solid matter is liquefaction residue and solid heteropolyacid catalyst; (3) regeneration of solid heteropolyacid: reclaim step (2) The solid heteropolyacid was dehydrated in an ove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com