Device for measuring radial pressure of underground sucker rod

A technology of radial pressure and sucker rod, applied in the direction of measuring device, measuring force, instrument, etc., can solve the problem that the size of the radial pressure of the sucker rod cannot be detected, the actual value of the sucker rod cannot be detected, and there is no measurement. device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

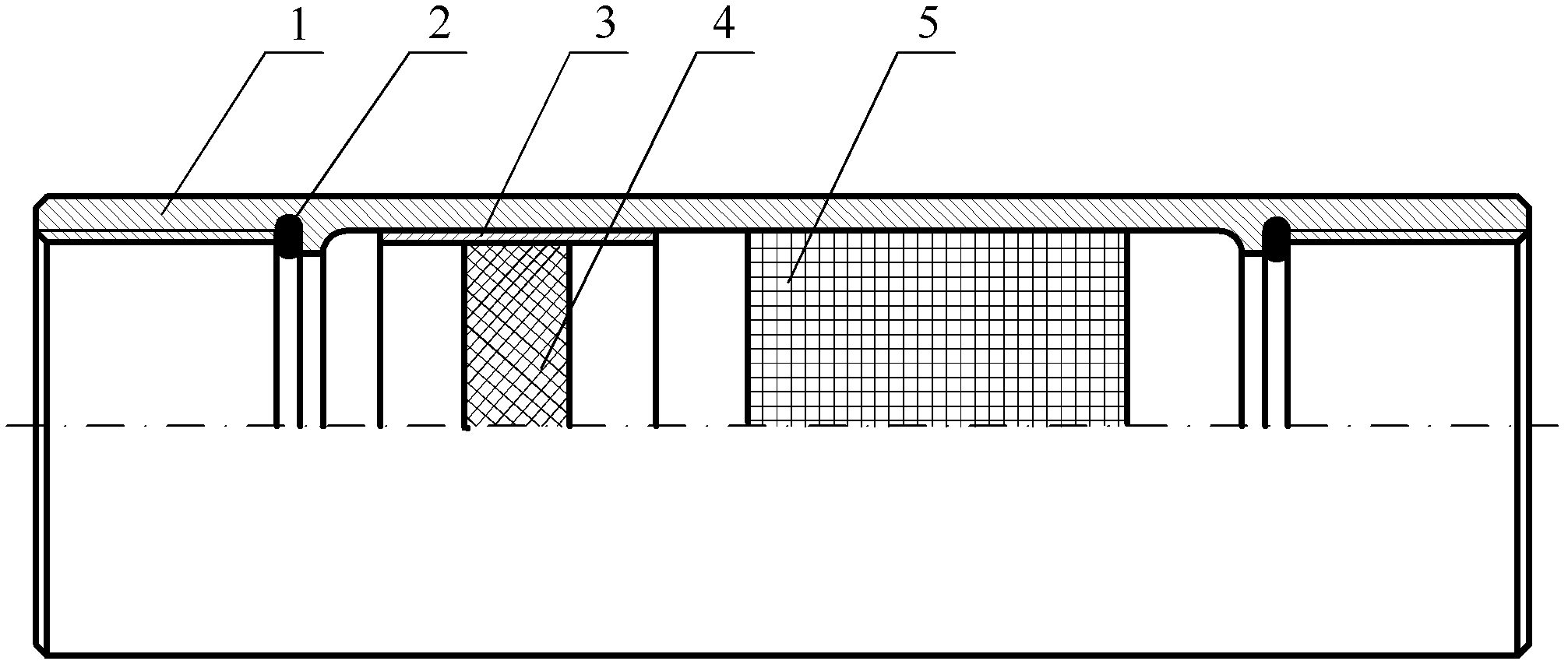

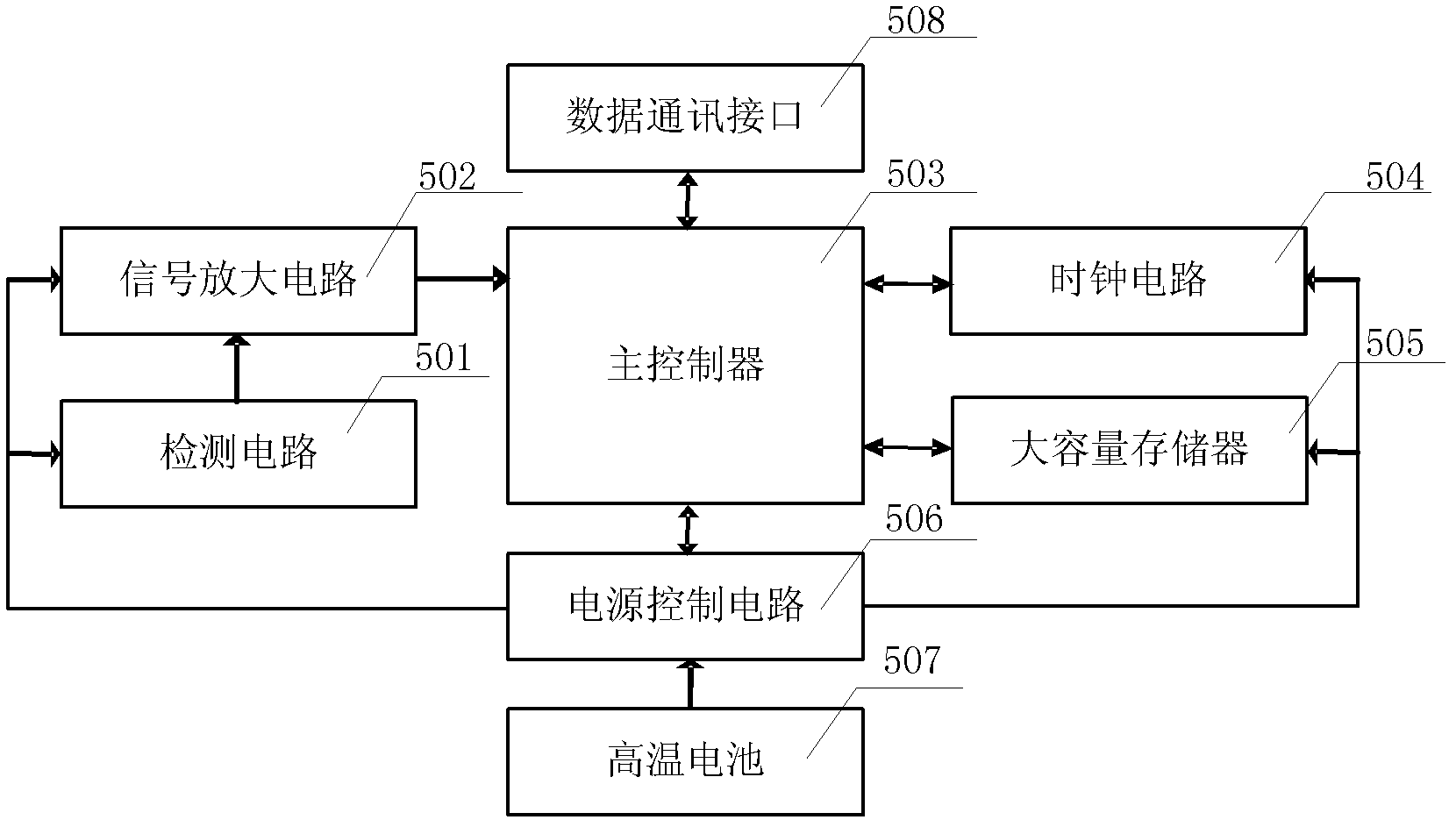

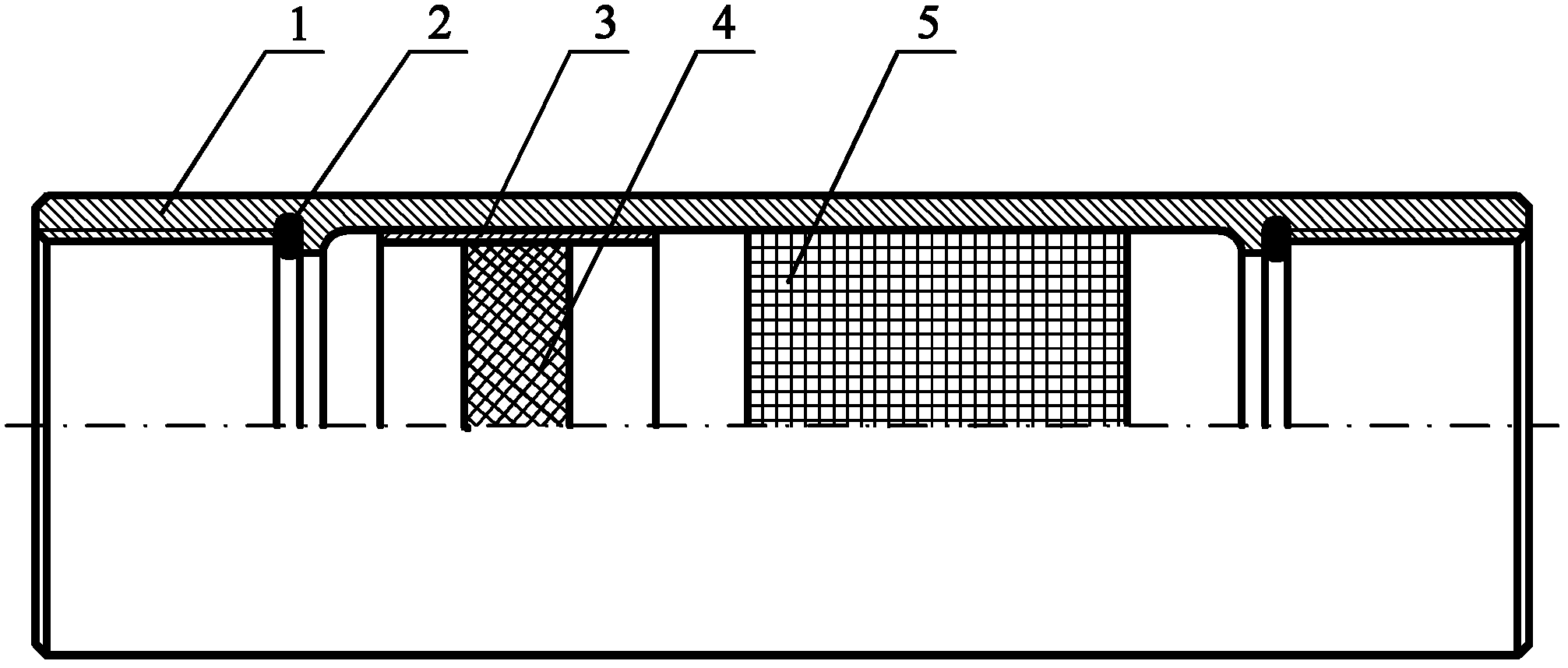

[0017] The present invention will be described in further detail below. A downhole radial pressure measuring device for sucker rods, comprising a short joint 1 with a through hole, see figure 1 , the shape is similar to the collar connected to the sucker rod, there is a section of internal thread at both ends of the through hole, and an annular groove is respectively opened at the inner end of the internal thread, and a sealing ring 2 is placed in the groove. The internal thread of the pup joint 1 is connected with the external thread of the sucker rod. After the sucker rod is tightened, the top of the sucker rod presses the sealing ring 2 to seal with the outside world. An elastic annular bushing 3 is closely attached to the inner surface of the through hole of the pup joint 1 , and the resistance strain gauge 4 is pasted on the inner surface of the annular bushing 3 . The integrated circuit system 5 is installed inside the short section 1, see figure 2 The integrated circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com