Batch valve core air-tightness test device

A test device and valve core technology, which is used in liquid/vacuum measurement for liquid tightness, and detection of the appearance of fluid at the leak point, etc., can solve the problem of complex operation, low work efficiency, and inability to meet batch and rapid detection. and other issues to ensure personal safety, improve efficiency and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

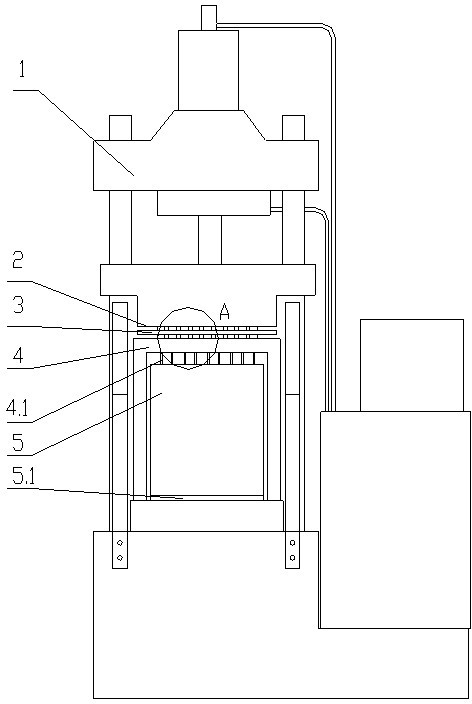

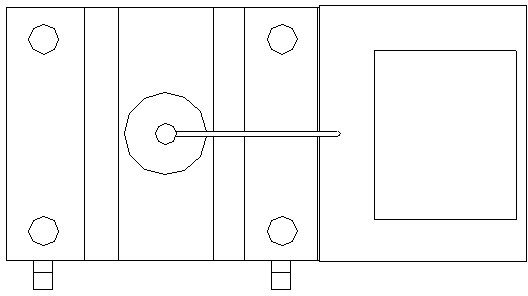

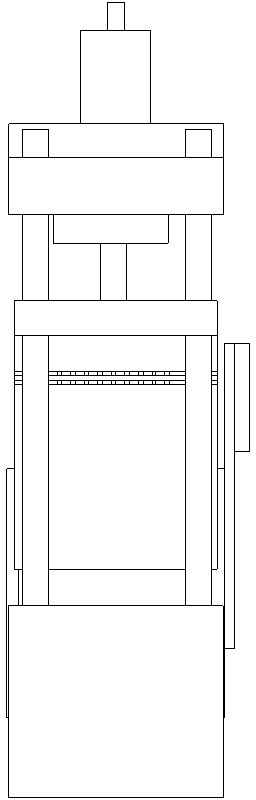

[0036] see figure 1 and image 3 , the present invention relates to a batch of valve core air tightness testing device, which is mainly composed of a press body 1, an upper template 2, a lower template 3, an exhaust plate 4, a water tank 5, a guide plate 6 and a sieve plate 7.

[0037] The upper template 2 is fixed on the upper working surface of the press body 1, the water tank 5 is arranged on the lower working surface of the press body 1, an exhaust plate 4 is arranged above the water tank 5, and on the exhaust plate 4 A plurality of exhaust pipes 4.1 are evenly distributed, and the exhaust pipes 4.1 are inserted under the liquid level in the water tank 5. A plane mirror 5.1 is arranged at the bottom of the water tank 5, and at least one side of the observation surface of the water tank 4 is made of a transparent material. Yes, such as glass, transparent plastic panels, etc.

[0038] see Figure 4 , a spring 2.2 and a slider 2.1 are embedded in the upper mold hole of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com