Control method for tensioning force of hydraulic jack

A technology of hydraulic jack and control method, which is applied in the direction of measuring fluid pressure, force/torque/work measuring instrument, and testing of machine/structural components, etc. Low accuracy, jacks cannot be interchanged, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1). Obtain the two data of "oil pressure - output force" and "oil pressure - oil indication value" at one time:

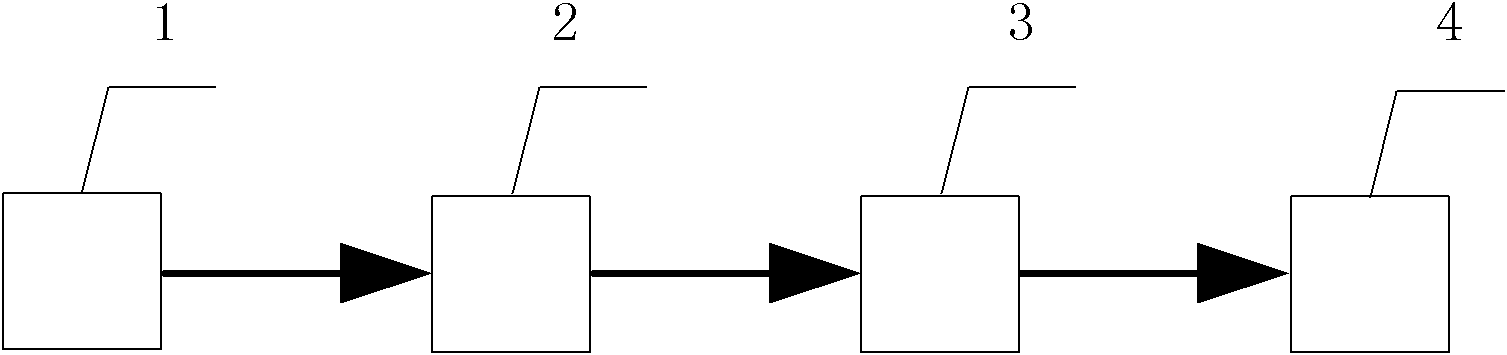

[0020] Such as figure 1 As shown, the tensioning equipment system: jacks, oil pumps, standard oil gauges, measuring oil gauges, and oil pipes are calibrated for "oil pressure-output force" and "oil pressure-oil indication value", and store the tensioning equipment system The two calibration data of "oil pressure - output force" and "oil pressure - oil indication value"; the calibration work is carried out on the press, and the oil pressure and oil indication value are recorded and stored point by point based on the active working state of the jack. Value and output force, take the average value of three measurements, and automatically make a graph that can be stored and read or draw a curve.

[0021] 2). Set and store the minimum and maximum values of the output force of the jack once stretched, and the accumulated stretching times of the jack's actual st...

Embodiment 2

[0025] 1). Obtain the two data of "oil pressure - output force" and "oil pressure - oil indication value" in two successively; you can also fill in one data if one data is missing:

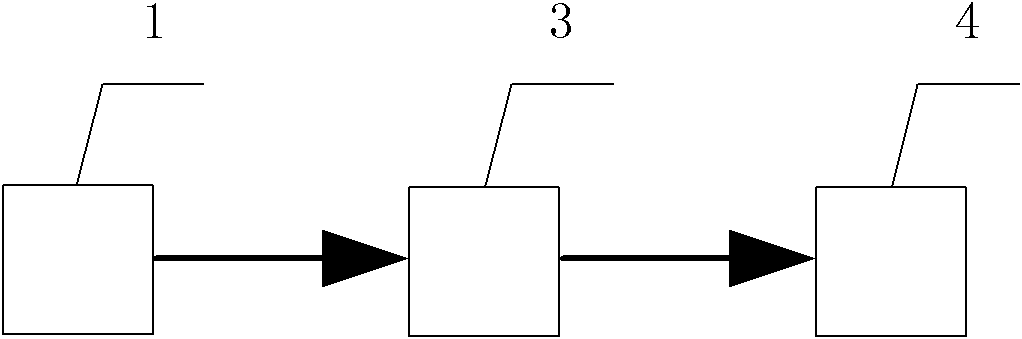

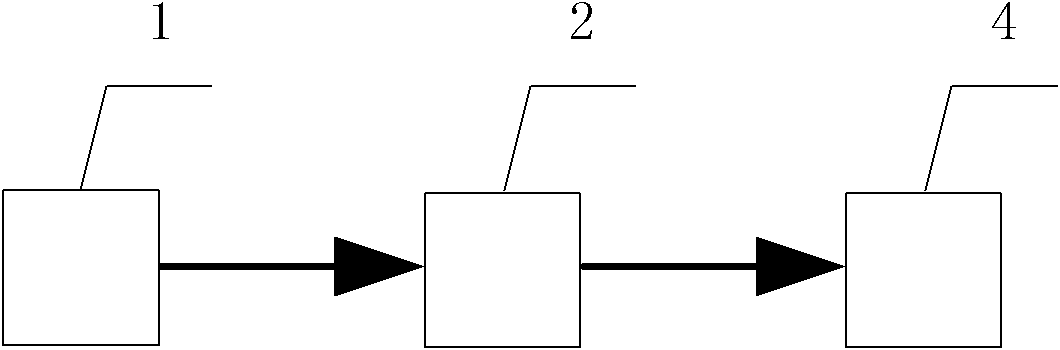

[0026] Such as image 3 As shown, the tensioning equipment system: jacks, oil pumps, standard oil gauges, and oil pipes are calibrated "oil pressure-output force", and the "oil pressure-output force" calibration data of the tensioning equipment system are stored; Figure 4 As shown, the tensioning equipment system: oil pump, standard oil gauge, measuring oil gauge, and oil pipe are calibrated "oil pressure - oil indication value", and the "oil pressure - oil value" of the oil pump, standard oil gauge, measuring oil gauge, and oil pipe is stored. —Oil indication value” calibration data; the calibration work of the jack is carried out on the press machine, based on the active working state of the jack, record and store the oil pressure and output force point by point, take the average value of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com