Miniaturization substrate integrated multi-beam antenna

A multi-beam antenna and substrate integration technology, applied in the direction of antenna, antenna array, radiating element structure, etc., can solve the problems of complex design and large volume, achieve compact structure, high radiation efficiency, reduce area and complex structure degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

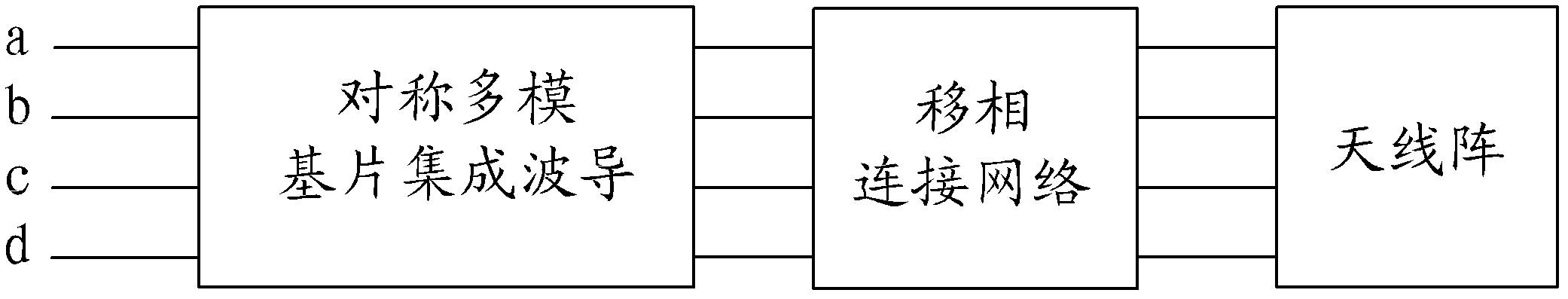

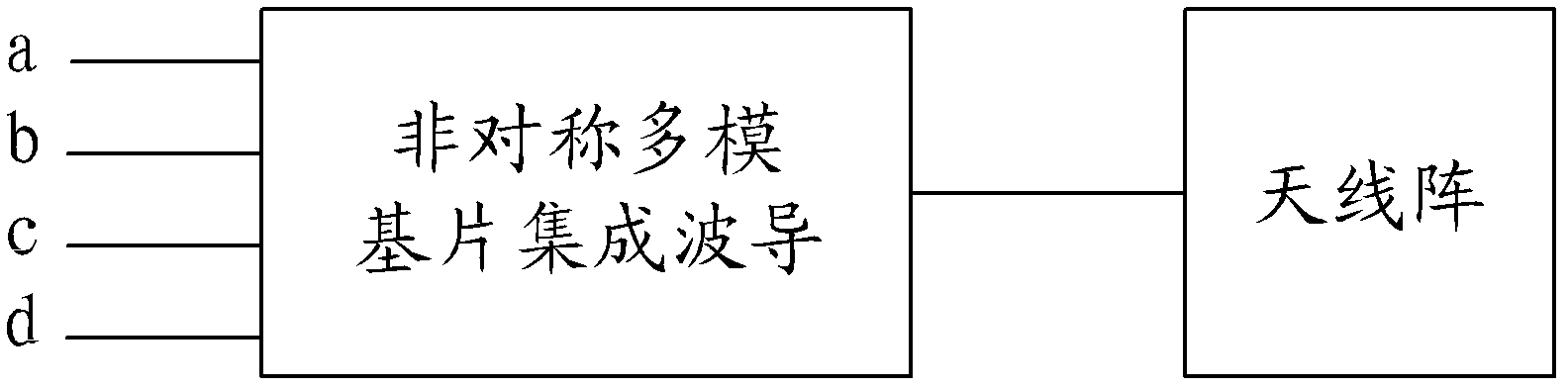

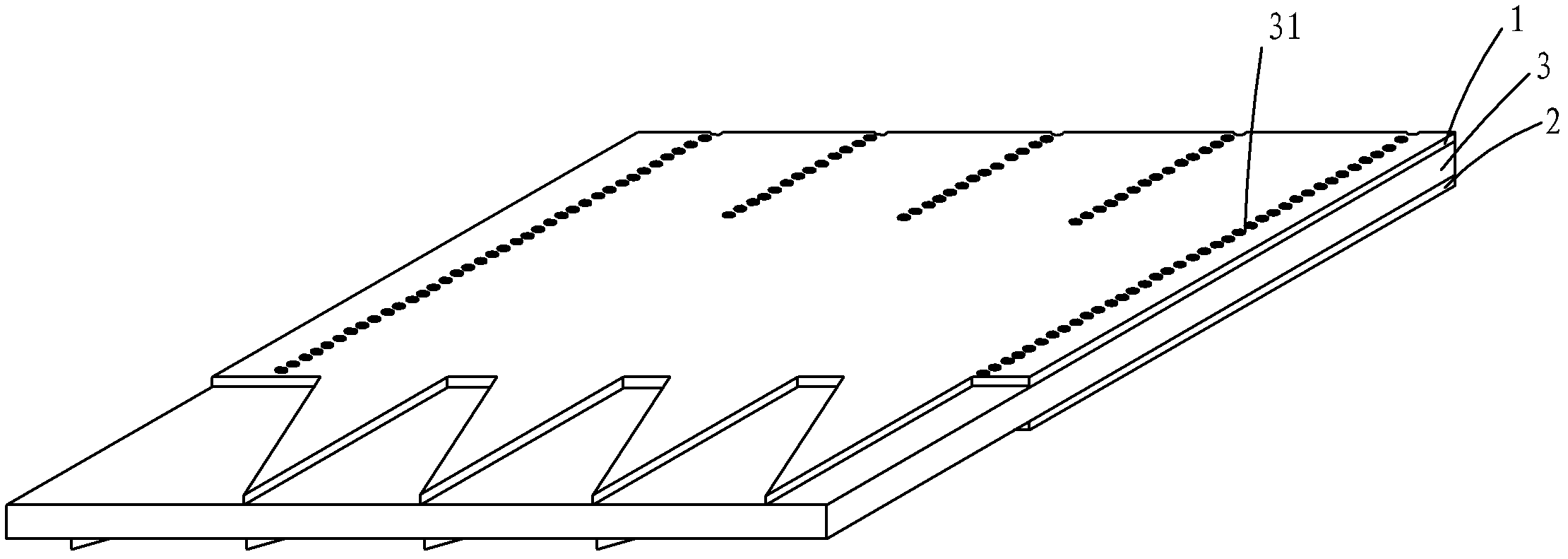

[0015] Such as figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, a miniaturized substrate-integrated multi-beam antenna includes a metal copper-clad upper layer 1, a dielectric layer 3, and a metal-clad copper lower layer 2 stacked sequentially from top to bottom. In order to form the miniaturized substrate integrated multi-beam antenna of the present invention For the antenna, the metal copper-clad upper layer 1 and the metal copper-clad lower layer 2 are processed through the printed circuit board manufacturing process to form the required metal pattern (circuit structure), and the various parts of the pattern are divided by virtual dotted lines, The medium layer 3 is drilled and the surface of the hole is metallized to form a metallized through hole 31, and the metal-clad copper upper layer 1 includes a direction from the input end to the radiation end ( Figure 5 The feeding table area 11 arranged in sequence from right to left in the middle, the multi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com