Method and apparatus for separating gaseous component

A component and gaseous technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as high noise load, high space location requirements, unfavorable compressors, etc., and achieve low operation and investment costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The direction of flow is indicated below by arrows.

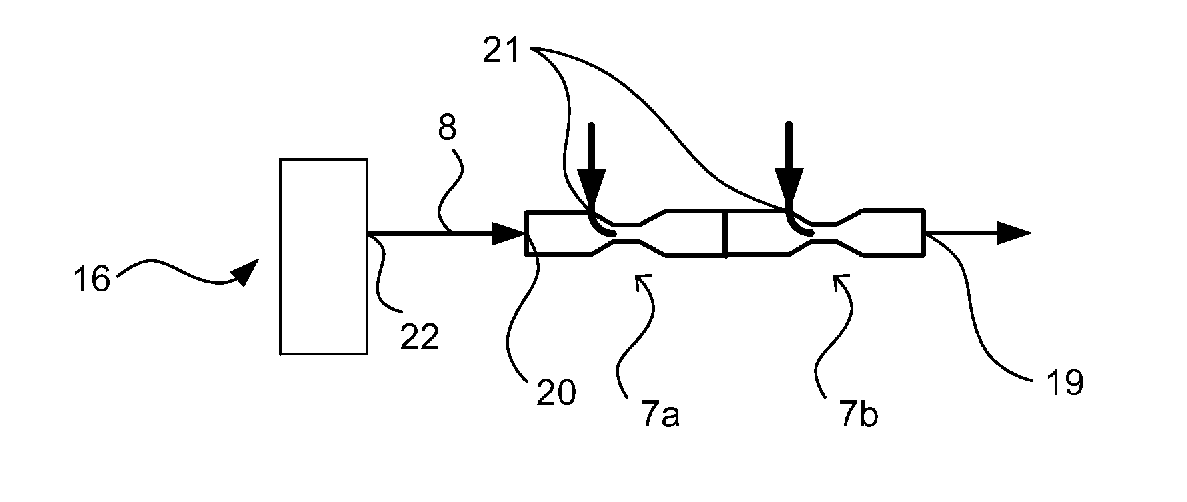

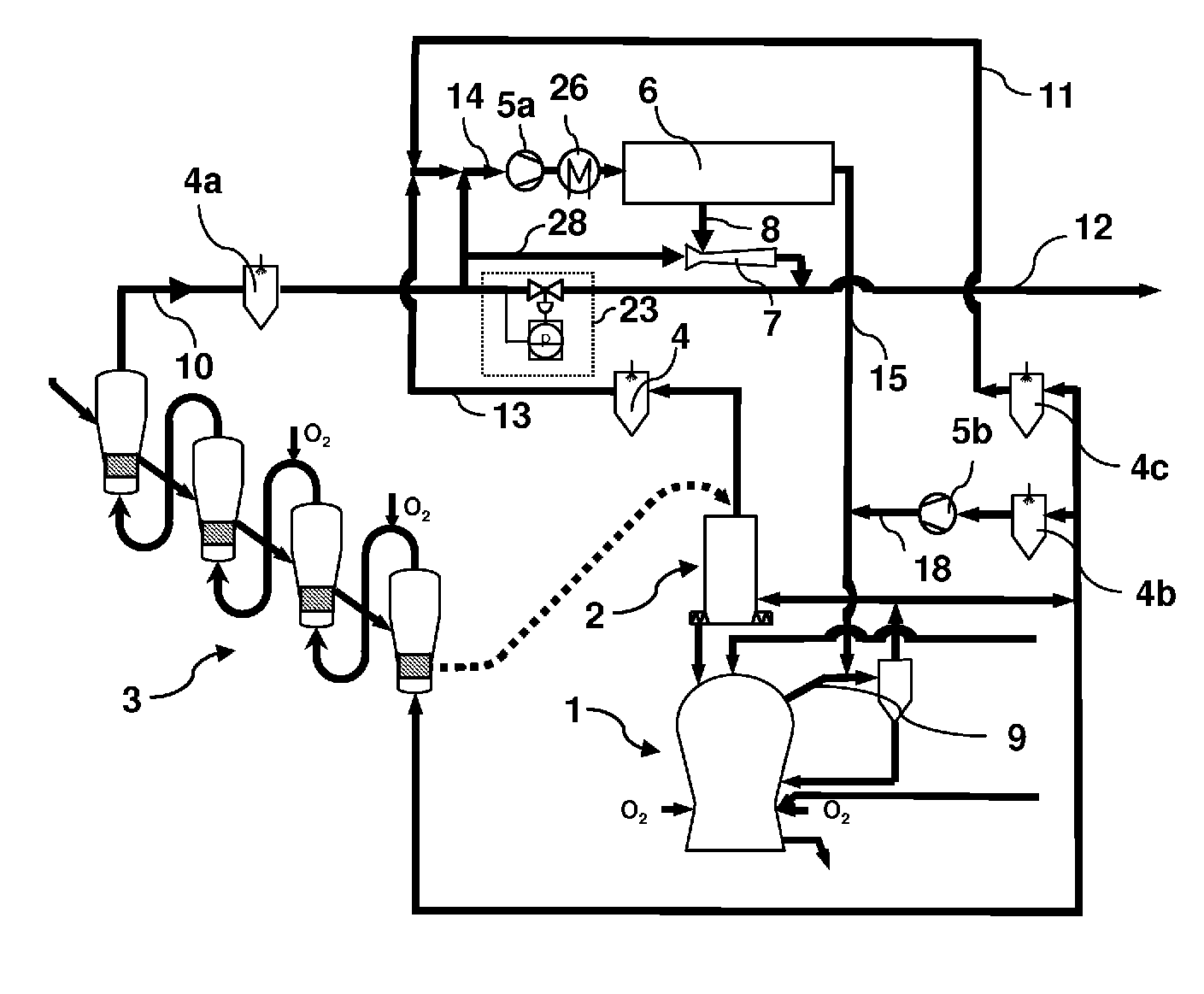

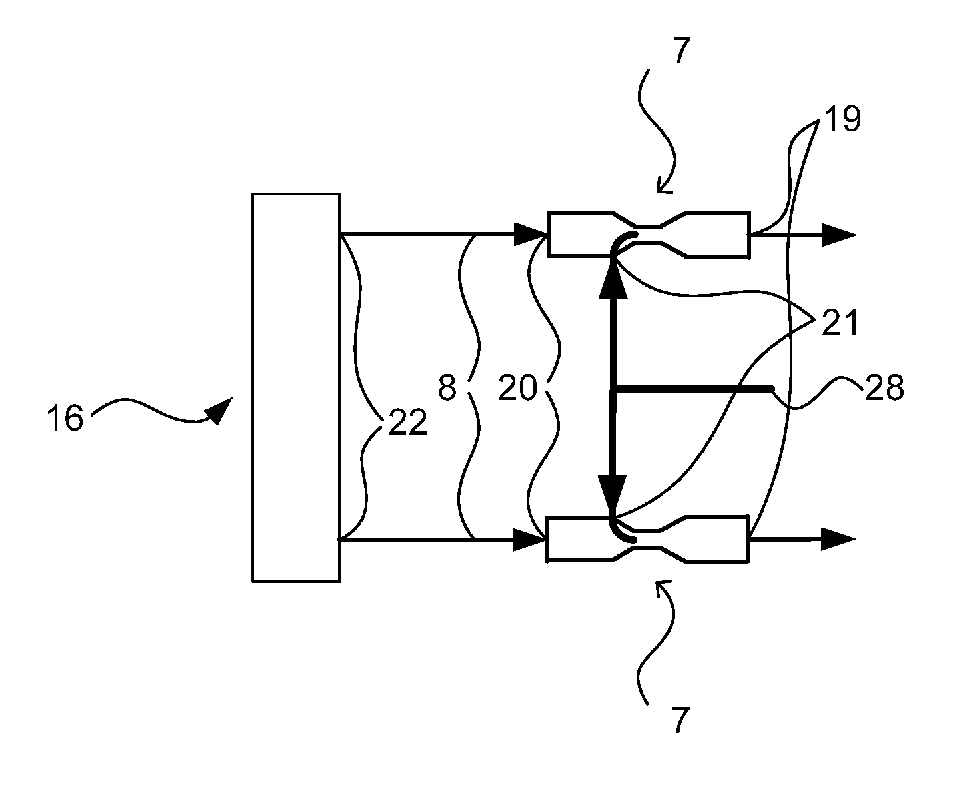

[0032] exist figure 1 shows a smelting reduction plant for the production of liquid pig iron on the basis of fine ore. If necessary, the fine ore is treated with additives in a cascade consisting of a plurality of pre-reduction reactors 3 (four vortex bed reactors are shown, 2 or 3 vortex bed reactors can also be used optionally). pre-reduced and subsequently loaded into reduction reactor 2. The loaded material is further reduced and preheated in the reduction reactor 2 . However, it is also possible to dispense with further reduction in the reduction reactor 2 , whereby the gas scrubber 4 and the line for the top gas 13 are omitted. The pre-reduction in the pre-reduction reactor 3 or the reduction in the reduction reactor 2 is carried out by means of the reducing gas 9 produced in the melter-gasifier 1, which is introduced into the reduction reaction after dedusting 2 and lead successively through individual pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com