Electro-pneumatic pressure regulation module comprising pressure regulation channels having separate pneumatic circuits

A technology of pressure regulation and pneumatic circuit, which is applied in the direction of brake transmission, brakes, brake components, etc., and can solve problems such as pressure channel failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

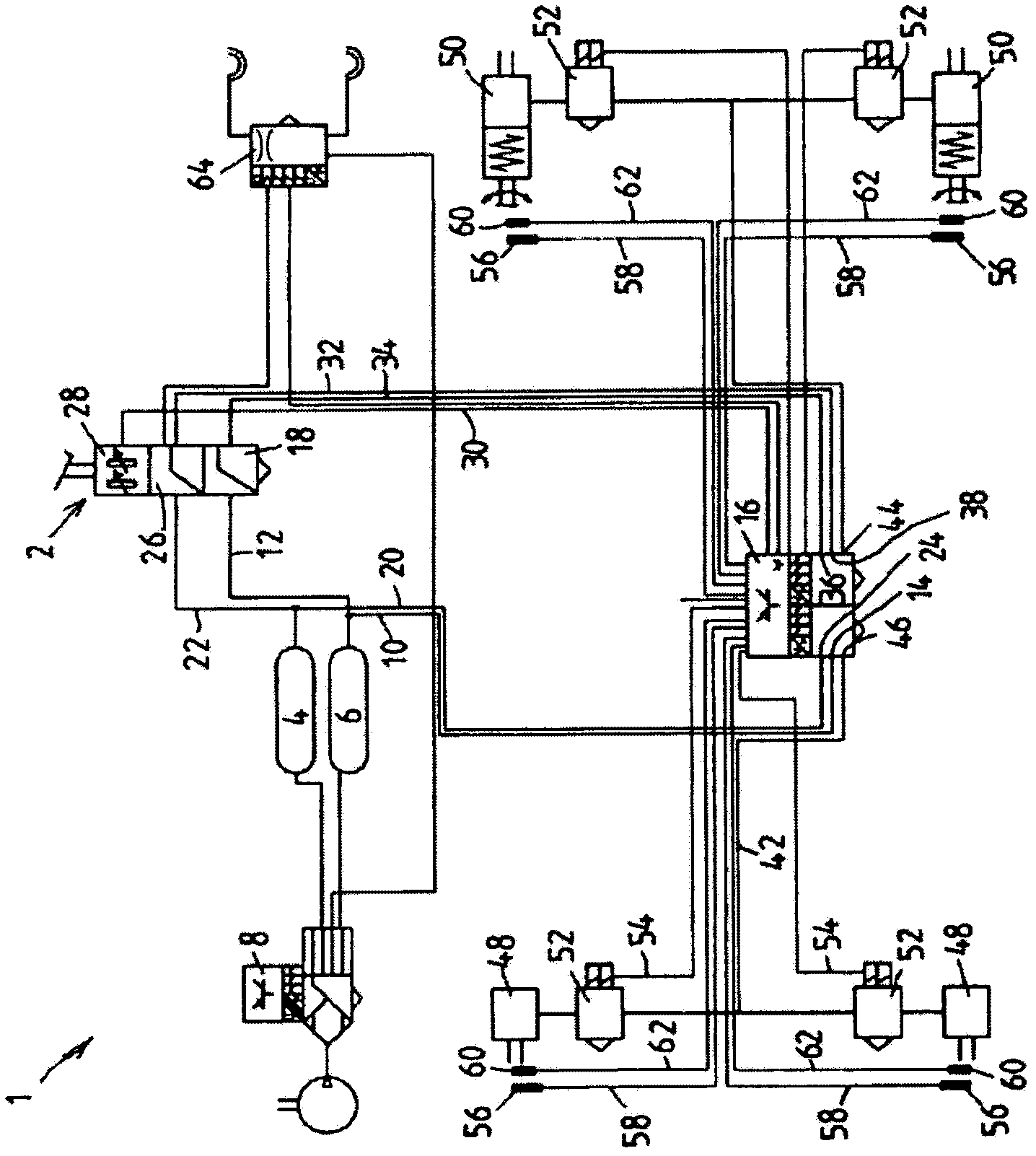

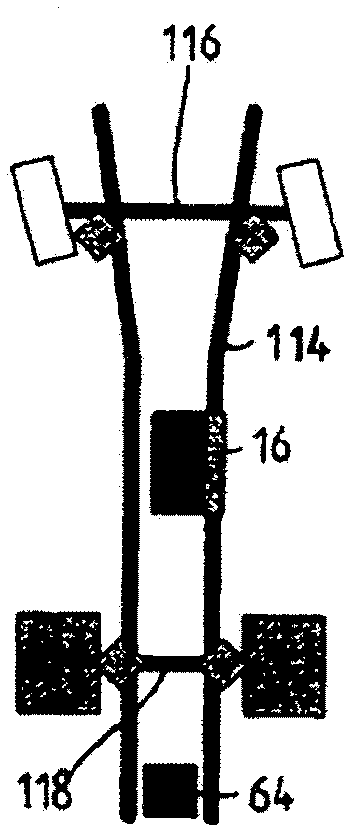

[0039] figure 1 A circuit diagram of an electropneumatic service brake system 1 for a commercial vehicle is shown, which has: a foot brake parameter sensor 2; a front axle reserve pressure vessel 4 for supplying the front axle pressure circuit or front axle pressure channel; Axle reserve pressure vessel 6 for supplying the rear axle pressure circuit or rear axle pressure channel.

[0040] Air supply, air conditioning and security are implemented as required by law via an air conditioning module 8 which is not described in detail here.

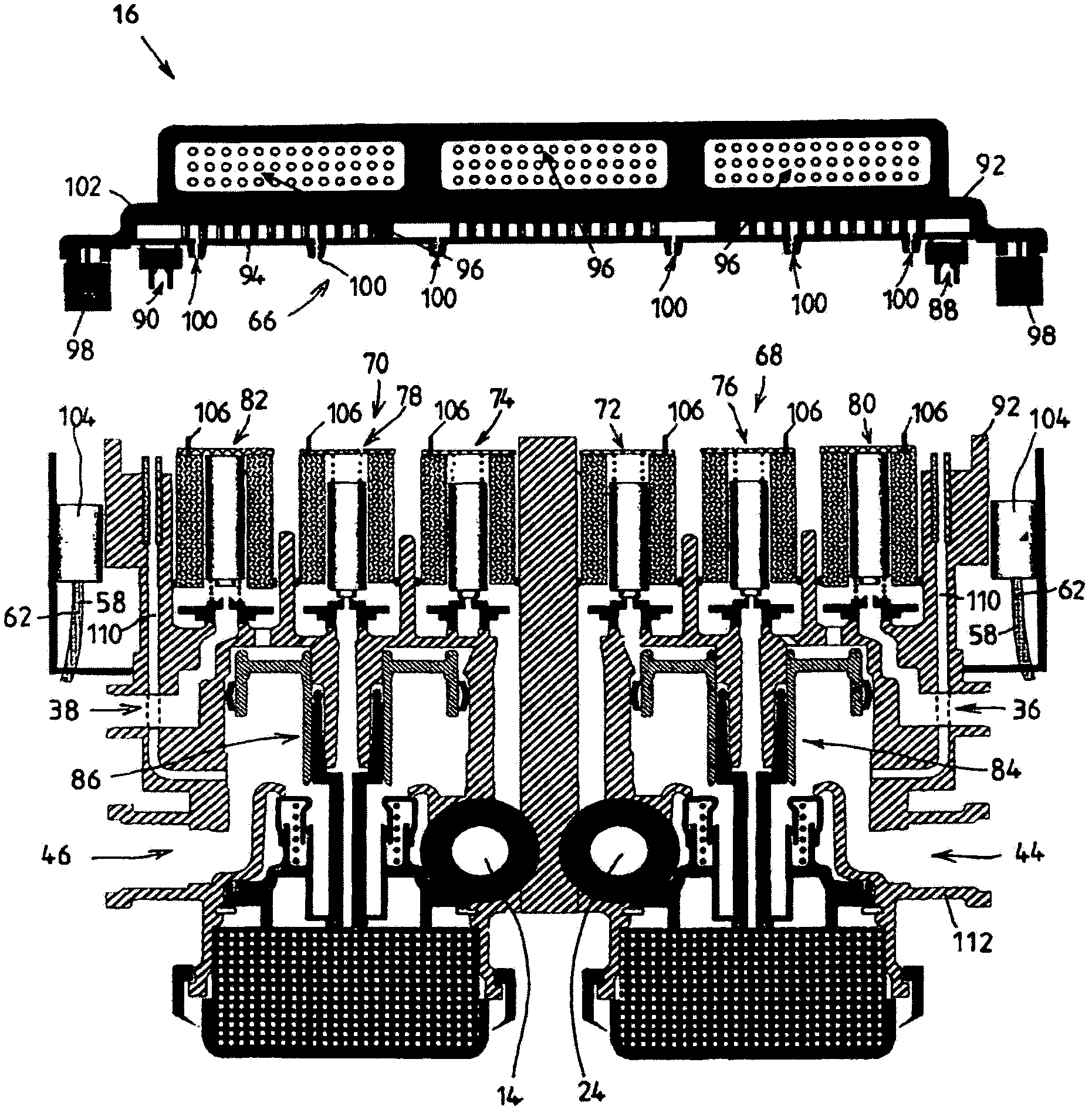

[0041] The rear axle reserve pressure container 6 is connected to the rear axle reserve interface 14 of the dual channel pressure regulating module 16 and connected to the front axle foot brake valve 18 of the foot brake parameter sensor 2 through the pneumatic supply pipelines 10 and 12 .

[0042] In a similar manner, the front axle reserve pressure container 4 is connected to the front axle reserve interface 24 of the dual-channel pressure r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com