Guide rail

A technology of guide rails and slide rails, applied in the field of guide rails, can solve the problems of weak structure, easy swing up and down, affecting the smoothness and stability of guide rail operation, and achieve the effects of long service life, smooth and stable operation, and simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

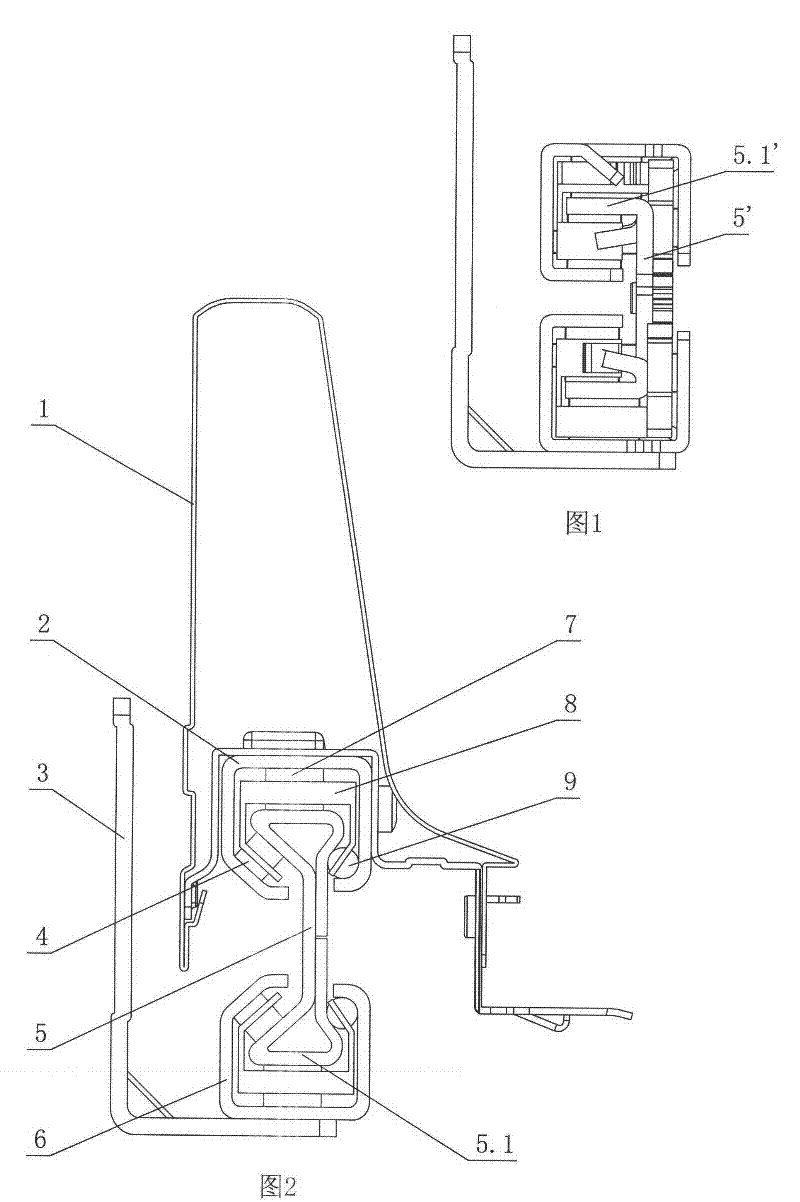

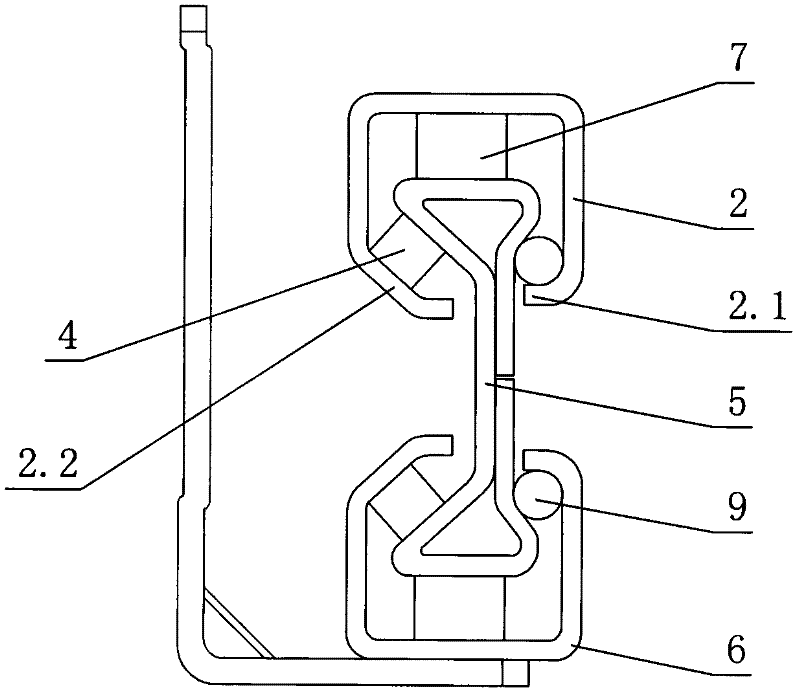

[0025] see figure 2 and image 3 , the guide rail includes three sliding rails, the upper slide rail 2, the middle slide rail 5 and the lower slide rail 6; Supporting part 5.1, the cage is sleeved outside the supporting part. The top surface of the upper support portion of the middle slide rail and the bottom surface of the lower support portion are both horizontal planes, and the cage 8 is provided with horizontal rollers 7 corresponding to the horizontal plane.

[0026] Balls 9 are provided on the inner side of the cage 8 corresponding to the support portion 5.1, and oblique rollers 4 are provided on the outer side corresponding to the support portion.

[0027] The above-mentioned guide rails have a symmetrical structure up and down. The upper slide rail 2 and the lower slide rail 6 are both in the shape of a frame with openings. Flange 2.2. The middle slide rail 5 is formed by bending sheet metal, and the thickness of the middle part of the middle slide rail is two she...

no. 2 example

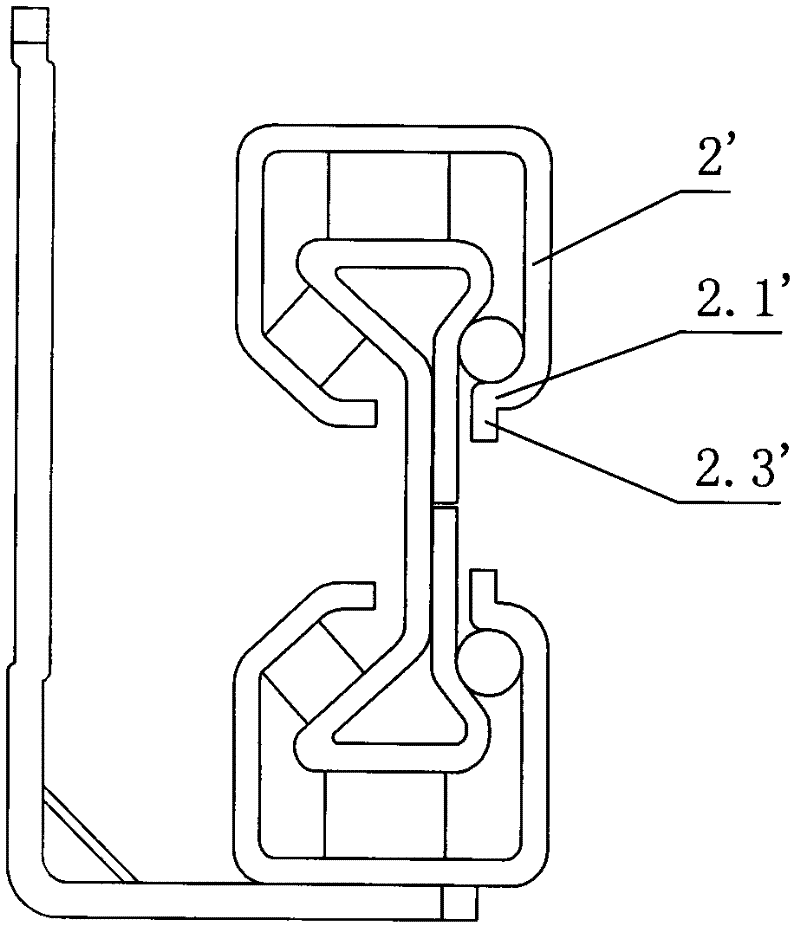

[0029] see Figure 4 The above-mentioned guide rails have a symmetrical structure up and down. Both the upper slide rail 2' and the lower slide rail are frame-shaped with openings. Oblique flanging; the end of the ball bearing flanging 2.1' is also provided with a vertical flanging 2.3'. Other unmentioned parts are the same as the first embodiment.

no. 3 example

[0031] see Figure 5 , the guide rail is left and right, up and down symmetrical structure, and the cage corresponds to the left and right sides of the middle slide rail 15 supporting portion to be provided with balls 9, and the upper slide rail 12 and the lower slide rail both sides are respectively provided with ball bearing flanging 12.1 corresponding to the balls. Other unmentioned parts are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com