Gate ejection structure of mould

A technology of ejection and mold, applied in the field of ejection gate structure of molds, can solve problems such as affecting mold output efficiency and increasing product rejection rate, and achieves reduction of cold spot probability, improvement of output efficiency, and increase of qualified rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

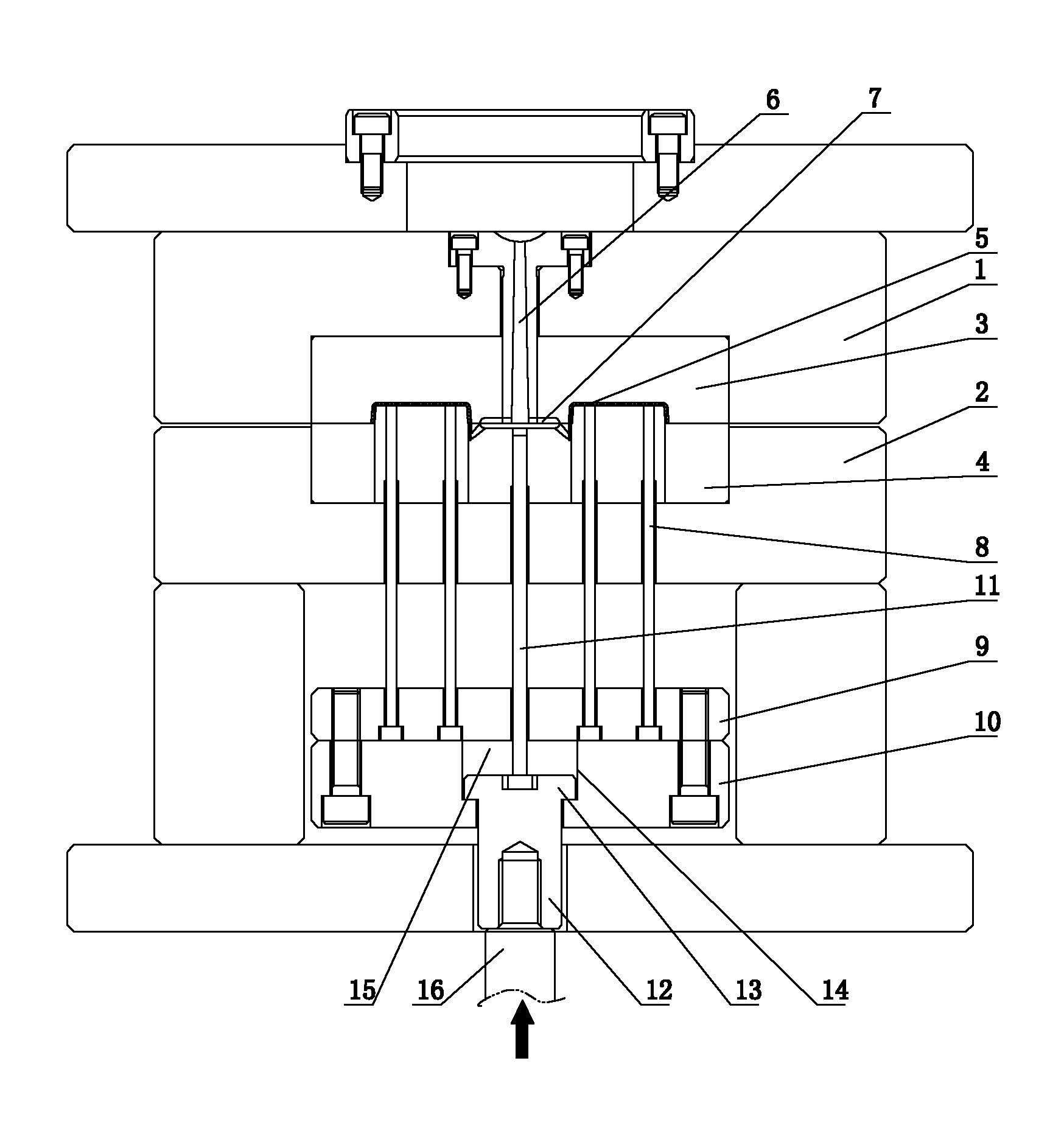

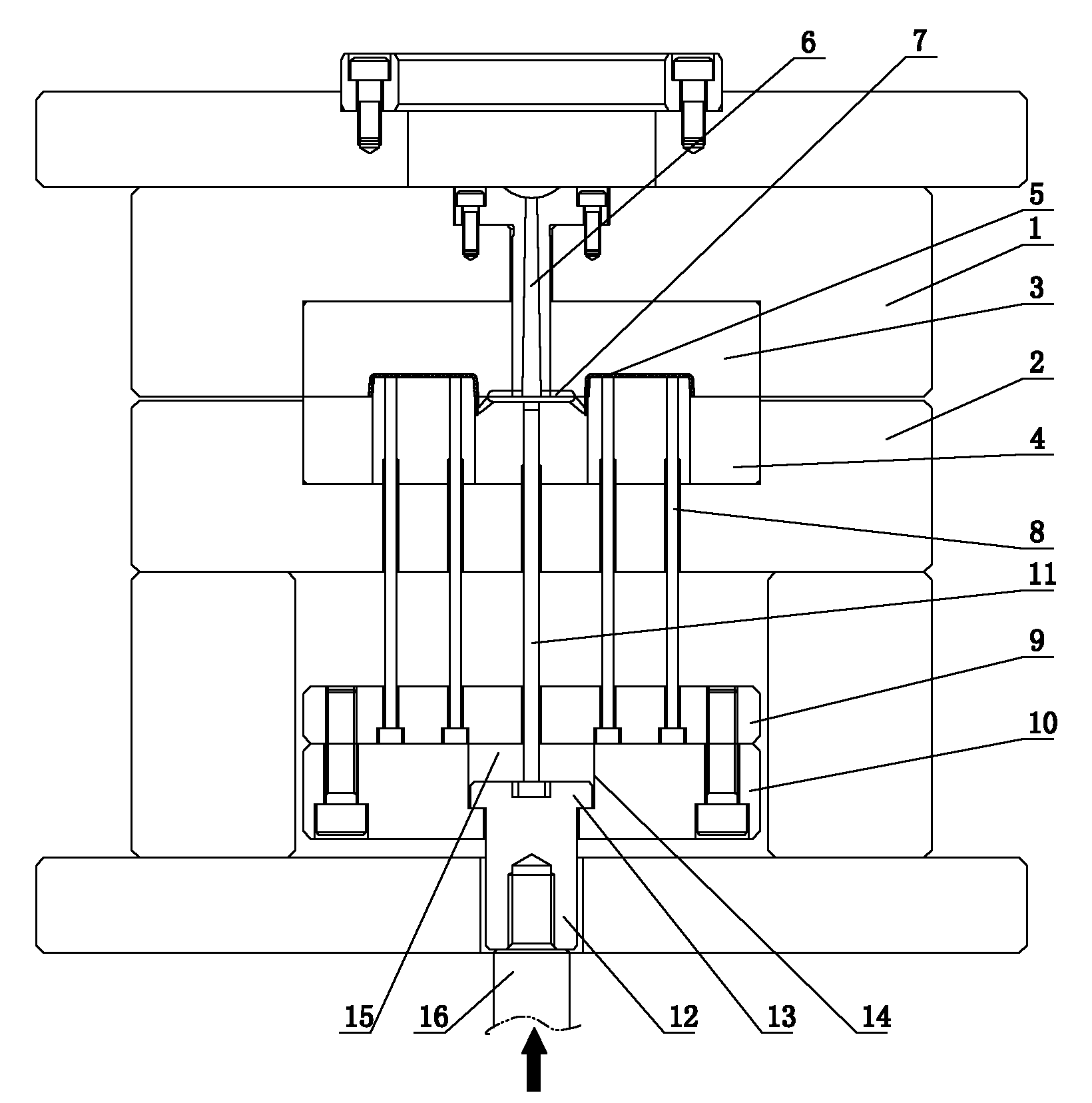

[0007] See figure 1 , which includes a front template 1, a rear template 2, a front mold core 3, a rear mold core 4, the cavity between the front mold core 3 and the rear mold core 4 is a mold cavity, and the product to be molded is located in the mold cavity 5, and the runner 6 After penetrating through the front model core 3, it is connected to the latent gate structure 7, and the latent gate structure 7 is connected to the cavity. The top end is mounted on the latent gate structure 7, the bottom end of the gate thimble 11 penetrates the face needle plate 9 and then fastens and connects the top boss 13 of the top block insert 12, and the bottom needle plate 10 is provided with a top with a large top and a small bottom. The block insert is installed through the groove 14, and the top boss 13 is installed on the upper groove body of the top block insert installed through groove 14, and there is a gap 15 between the bottom end surface of the needle plate 9 and the top surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com