Hanging basket cantilever method construction method of large-span continuous rigid beam sidespan cast-in-place beam section

A rigid-frame beam and cast-in-place technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of difficult erection of supports, inconvenient surrounding environment, and high safety risks, so as to reduce the intensity of aerial work and shorten the construction period. , the effect of low security risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The hanging basket hanging construction method of the side span cast-in-place beam section of the long-span continuous rigid frame beam is realized by the following steps:

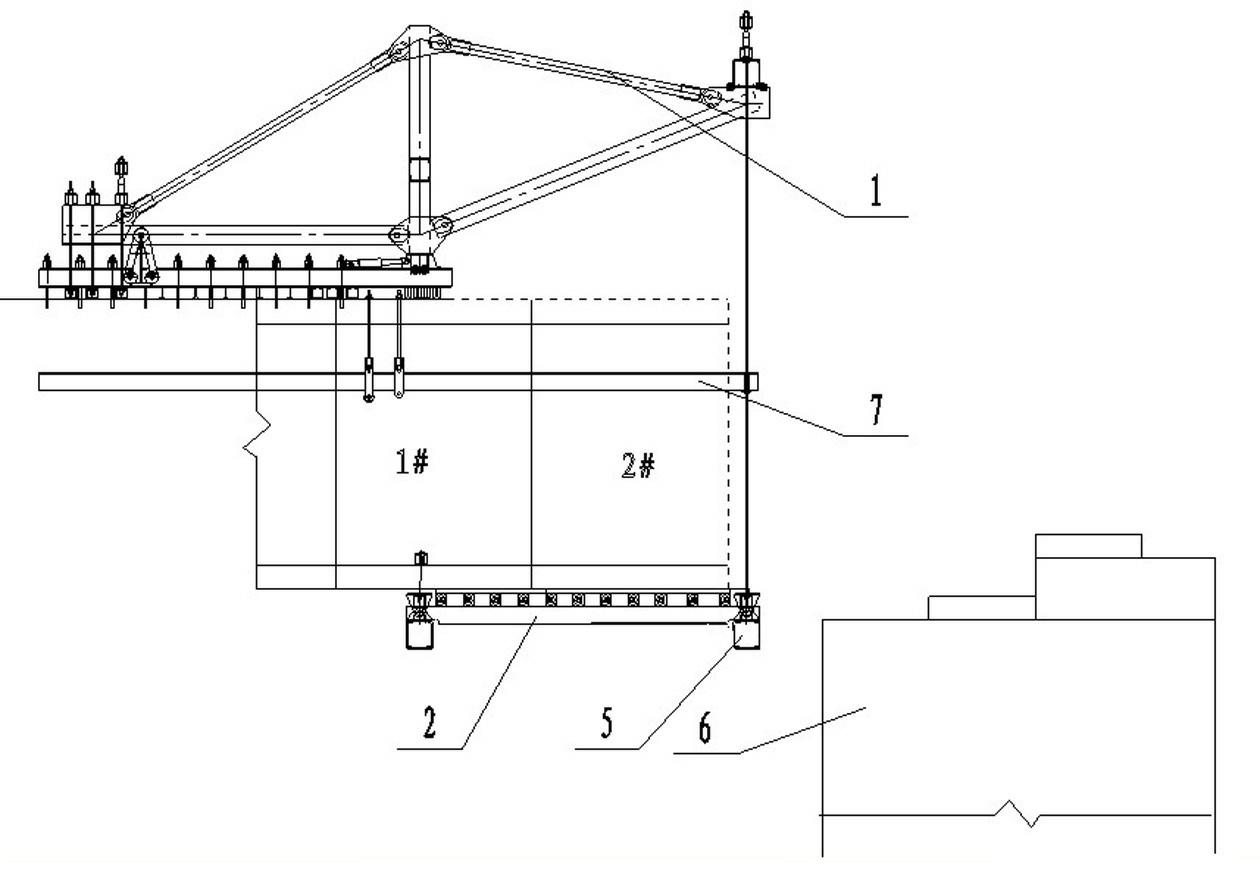

[0024] (1) After the middle span of the rigid frame beam is closed, move the hanging basket on one side of the side span forward, adjust the center line of the hanging basket, perform steel bar binding and prestress installation, and use the side-span hanging basket to cantilever one side of the outer side of the transition pier For # and 2# cast-in-place sections, the concrete reaches the design tensile strength and modulus of elasticity and then tensions the prestressed steel strands. At this time, the hanging basket is located on the 1# and 2# completed beam sections;

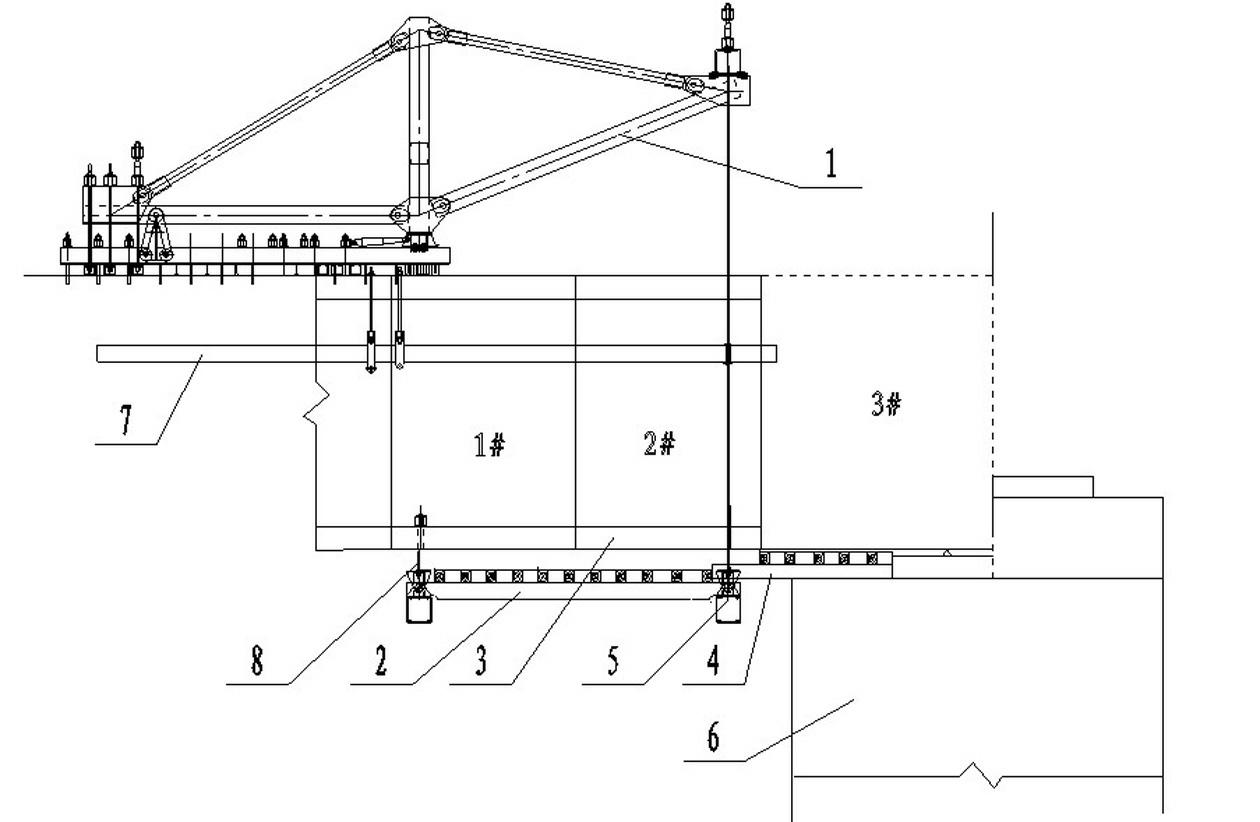

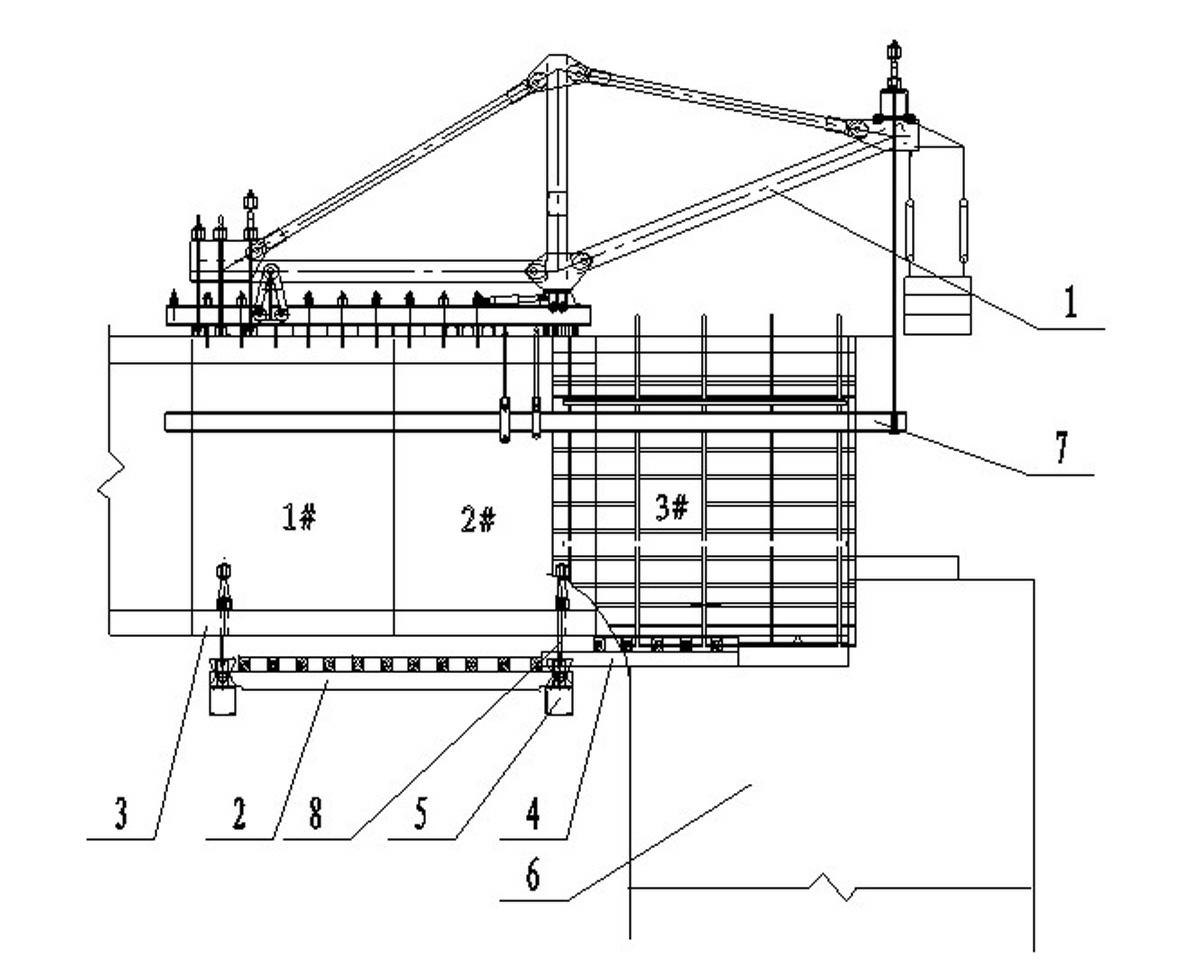

[0025] (2) Put the hanging basket on the pier, and carry out construction work on the 3# cast-in-place section:

[0026] Step 1: Release the hanging points of the inner and outer sliding beams, thereby separating the inner and out...

Embodiment 2

[0042] The hanging basket hanging construction method of the side span cast-in-place beam section of the long-span continuous rigid frame beam is realized by the following steps:

[0043] (1) After the middle span of the rigid frame beam is closed, move the hanging basket on one side of the side span forward, adjust the center line of the hanging basket, perform steel bar binding and prestress installation, and use the side-span hanging basket to cantilever one side of the outer side of the transition pier For # and 2# cast-in-place sections, the concrete reaches the design tensile strength and modulus of elasticity and then tensions the prestressed steel strands. At this time, the hanging basket is located on the 1# and 2# completed beam sections;

[0044] (2) Put the hanging basket on the pier, and carry out construction work on the 3# cast-in-place section:

[0045] Step 1: Release the hanging points of the inner and outer sliding beams, thereby separating the inner and out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com