Fully-spherical projection objective

A projection objective lens, a global technology, applied in optics, instruments, optical components, etc., can solve the problems of complex objective lens structure, long conjugate distance, high price, etc., and achieve high lithography efficiency, high object telecentricity, and reduced The effect of production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

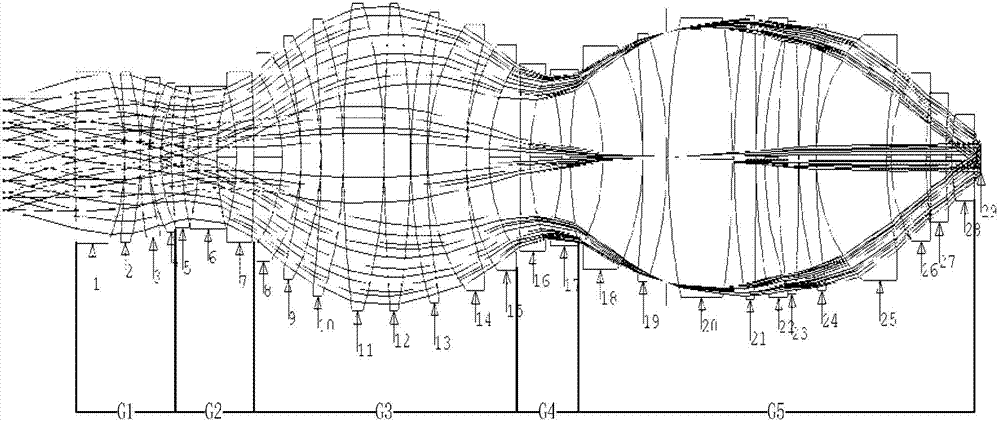

[0023] figure 1 It is a schematic diagram of the layout of the spherical projection objective lens of the present invention, 28 pieces of spherical lenses form the first lens group G1, the second lens group G2, the third lens group G3, the fourth lens group G4 and the fifth lens group G5, which are sequentially incident from the light beam The direction is set to form a double waist structure as a whole.

[0024] The first lens group G1 includes a first positive lens 1 , a second positive lens 2 , a first negative lens 3 and a first meniscus lens 4 . , the first lens group G1 has positive refractive power and converges the incident light beam. Wherein, the first positive lens 1 converges the light onto the second positive lens 2, the second positive lens 2 continues to converge the light, and the light reaches the firs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com