Electronic cam master controller

A master controller, electronic cam technology, applied in the field of electromechanical, can solve the problems affecting the normal operation of the equipment, complex mechanical structure, laborious operation, etc., to achieve the effect of convenient and quick adjustment, flexible operation and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

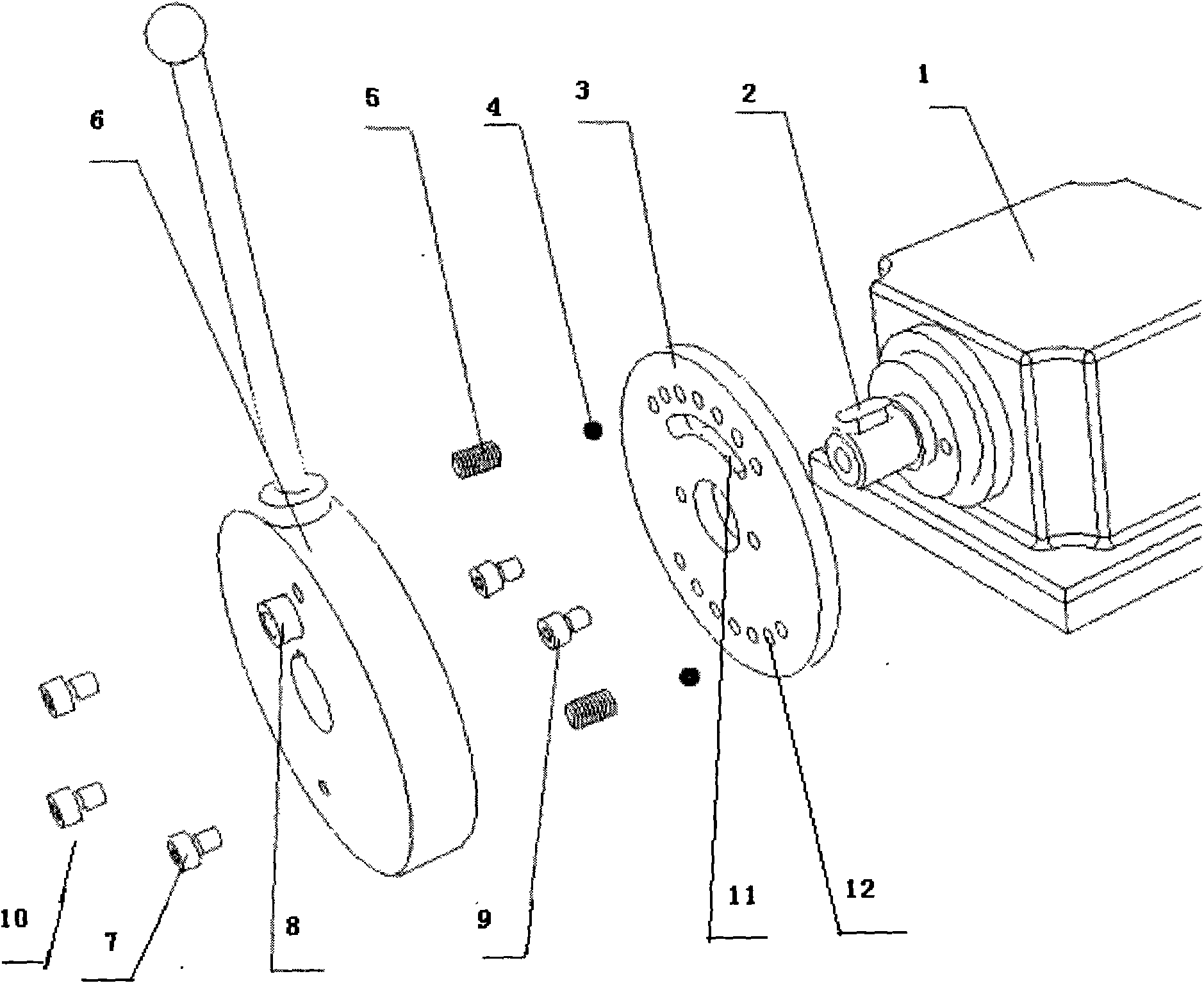

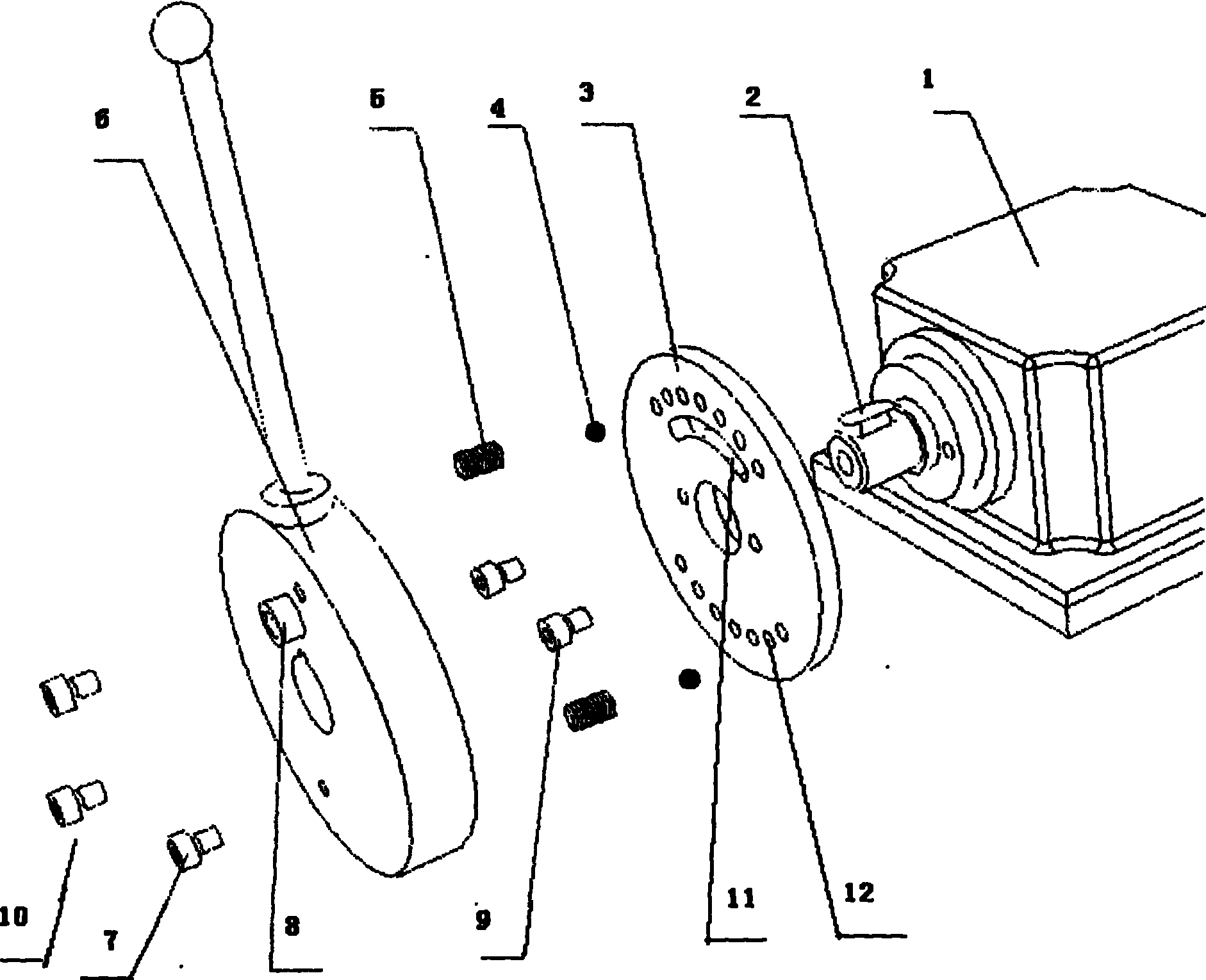

[0008] Example 1, see figure 1 , taking the handle forward by one gear, backward by five gears, and zero gear as an example, the standard electronic cam controller 1 is used. There is a key 2 on the electronic cam controller 1, and the positioning disc 3 is fixed with two positioning discs. 9 is fixed on the electronic cam controller 1. The positioning disc 3 has an annular groove 11 and a synchronous double row of positioning concave holes 12. The number of concave holes 12 on the positioning disc 3 can be determined by itself according to the number of required gears. The forward and backward operation of the handle 6 is not more than 180° as a standard. Of course, the length of the stop ring groove 11 on the corresponding positioning disc 3 also needs to be increased or decreased; The depth and diameter are determined by the size of the selected steel ball, and the steel ball can be embedded in the concave hole 1 / 2 as the benchmark. The steel ball of φ8.5mm is used in the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com