Automatic lamp filament feeding device of filament stretching machine

A filament stretching machine and filament technology, which is applied in the direction of machines with sequentially arranged working positions, can solve the problems of unable to pick and inspect filaments, and low work efficiency, and achieve the effects of automatic operation, improved production efficiency, and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

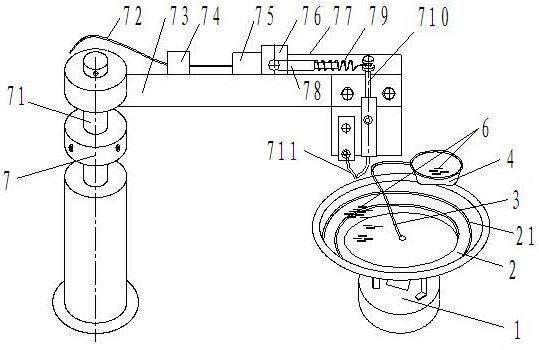

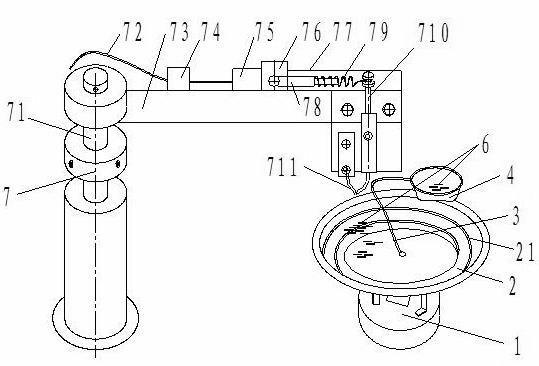

[0011] Such as figure 1 As shown, an automatic filament feeding device for a wire stretching machine, wherein: the filter disc 2 is fixed on the support platform 1, and the disc wall has a spiral upward step 21; one end of the connecting rod 3 is fixed at the bottom of the filter disc 2, and the other end is It is fixedly connected with the filter screen 4, and by adjusting the connecting rod 3, the filter screen 4 is placed above the opening of the filter disc 2; the support table 1 has a built-in vibrating block, and the filament 6 placed in the filter screen 4 is vibrated by the vibration of the vibrating block. Insert it into the filter disc 2, and make the filament 6 spirally move upward along the step 21 to the mouth of the filter disc.

[0012] Manipulator 7 comprises column 71 and rotating arm 73, is provided with fixed block 74, travel switch 75, slide block 76 successively on rotating arm 73, and slide block 76 slides along slideway 77 under the control of travel swi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com