Concrete building block cutting device

A technology of concrete blocks and cutting devices, which is applied in the direction of ceramic molding machines and manufacturing tools, which can solve the problems of potential safety hazards, easy injury, and low efficiency, and achieve the effects of stable transportation, easy cutting, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

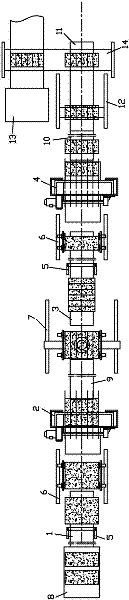

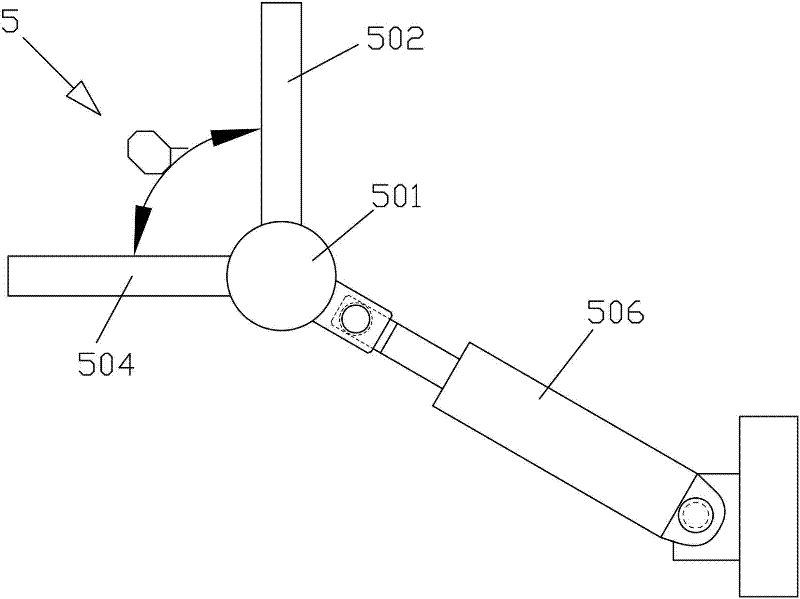

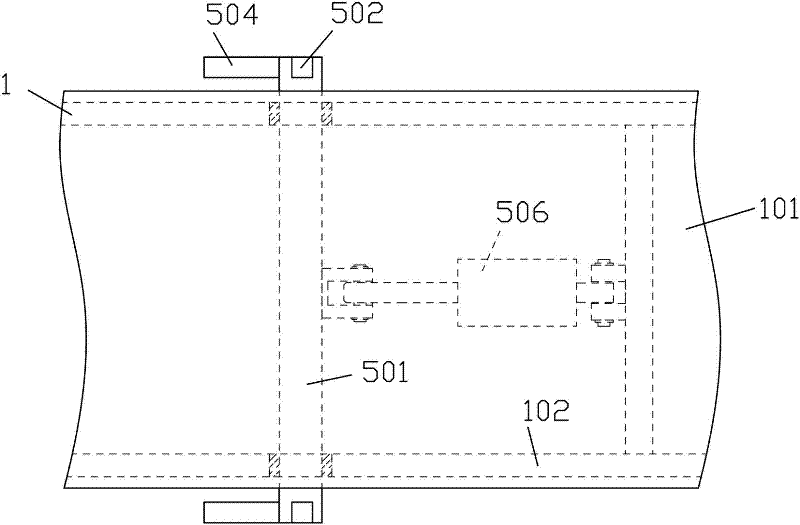

[0042] Examples, see attached figure 1 , 2, 3, 4, 5, 6, 7, 8, a concrete block cutting device, including the first conveyor belt 1, the first cutting machine 2, the second conveyor belt 3 and the second cutting machine 4, the first conveyor belt 1. The second conveyor belt 3 generally includes a deceleration motor, bracket and conveyor belt, etc., because it can be realized by those skilled in the art, so it will not be described in detail here. The block demoulding platform connected to the front end of the first conveyor belt 1 8. The block demoulding platform is used to place the block mold. The concrete blocks demoulded from the block mold are placed on the platform, and then transported to the first conveyor belt 1, where the first conveyor belt 1, Between the first cutting machine 2 and between the second conveyor belt 3 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com