Sliding block deviation correction mechanism of hydraulic press

A hydraulic press and deviation correction technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of large system flow, complex structure, low precision, etc., and achieve the effect of simple system structure, fast response speed, and reduced energy consumption of the host

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

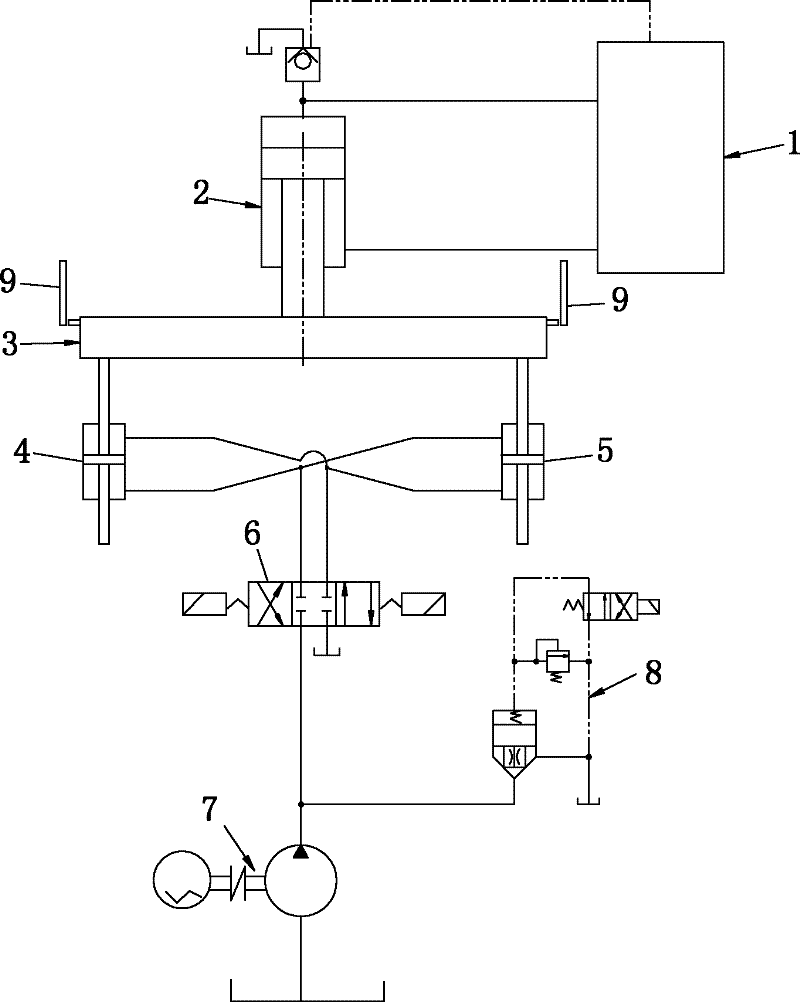

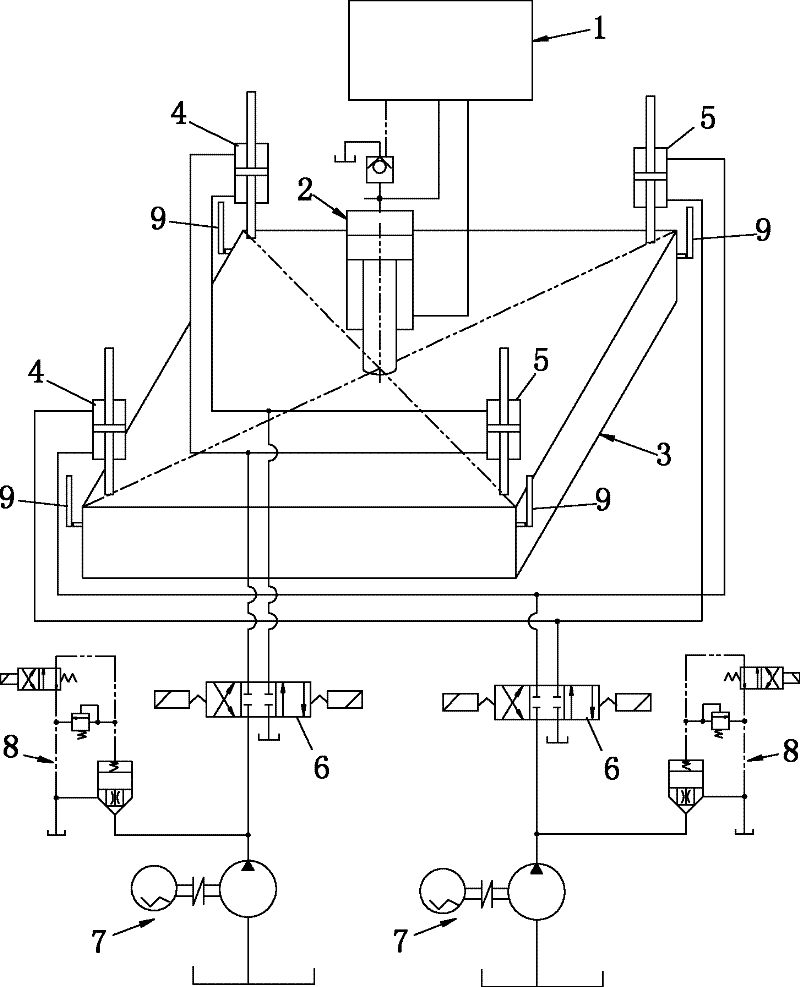

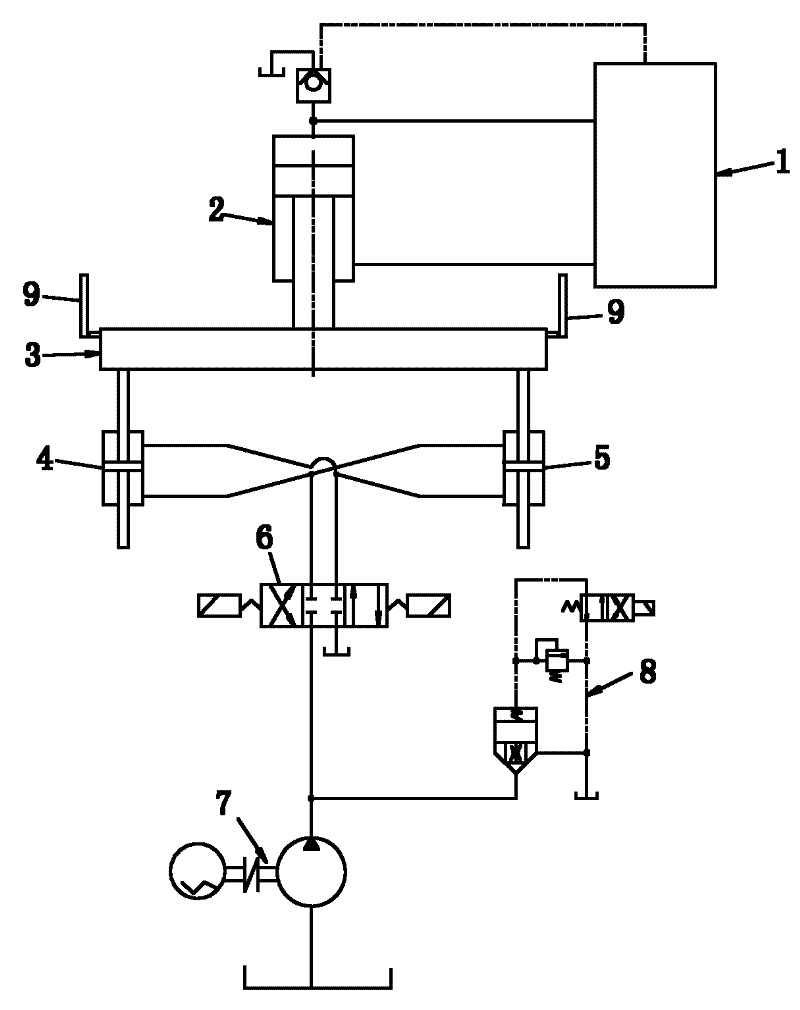

[0018] refer to figure 1 , using a double-cylinder form of correction mechanism, the correction mechanism is suitable for the slider 3 action surface of the long distance is greater than the width of the situation. Its specific structure: the slider 3 of the hydraulic machine is connected with a group of correction cylinders, the first correction cylinder 4 and the second correction cylinder 5 are connected to the left and right ends of the slider 3 with the main oil cylinder 2 as the center according to the symmetrical structure, the first correction cylinder The lower chamber of the cylinder 4 is connected with the upper chamber of the second deviation-correcting cylinder 5, the upper chamber of the first deviation-correcting cylinder 4 and the lower chamber of the second deviation-correcting cylinder 5 respectively through pipelines, and both pipelines are connected and controlled by the controller The proportional servo valve 6, the proportional servo valve 6 is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com