Large opposite-running perfect offset press

An offset printing machine and double-sided technology, applied in printing presses, rotary printing machines, lithographic rotary printing machines, etc., can solve problems such as dot deformation, cumulative error, easy deformation, etc., to improve transmission accuracy, reduce ghosting, and reduce errors Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

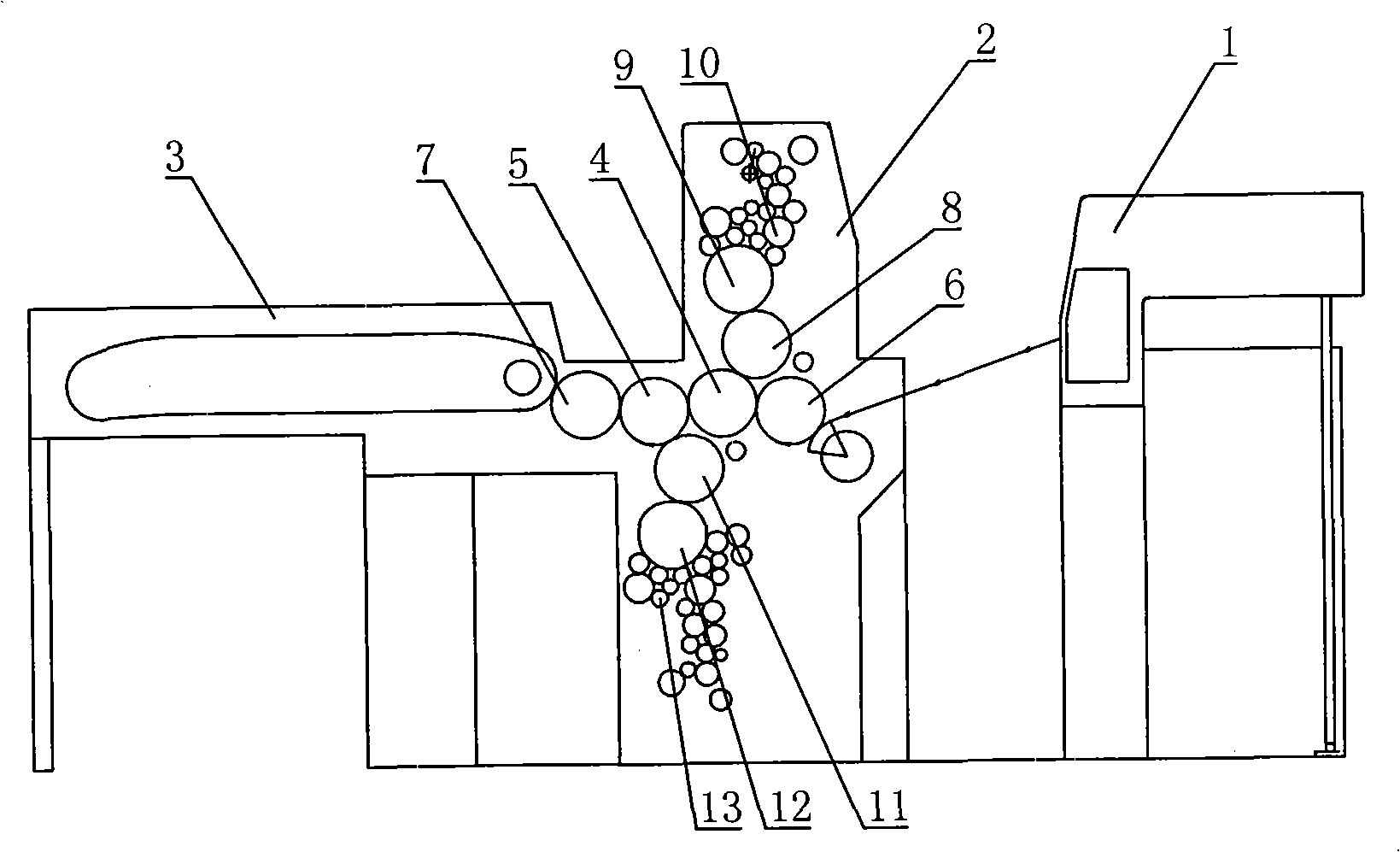

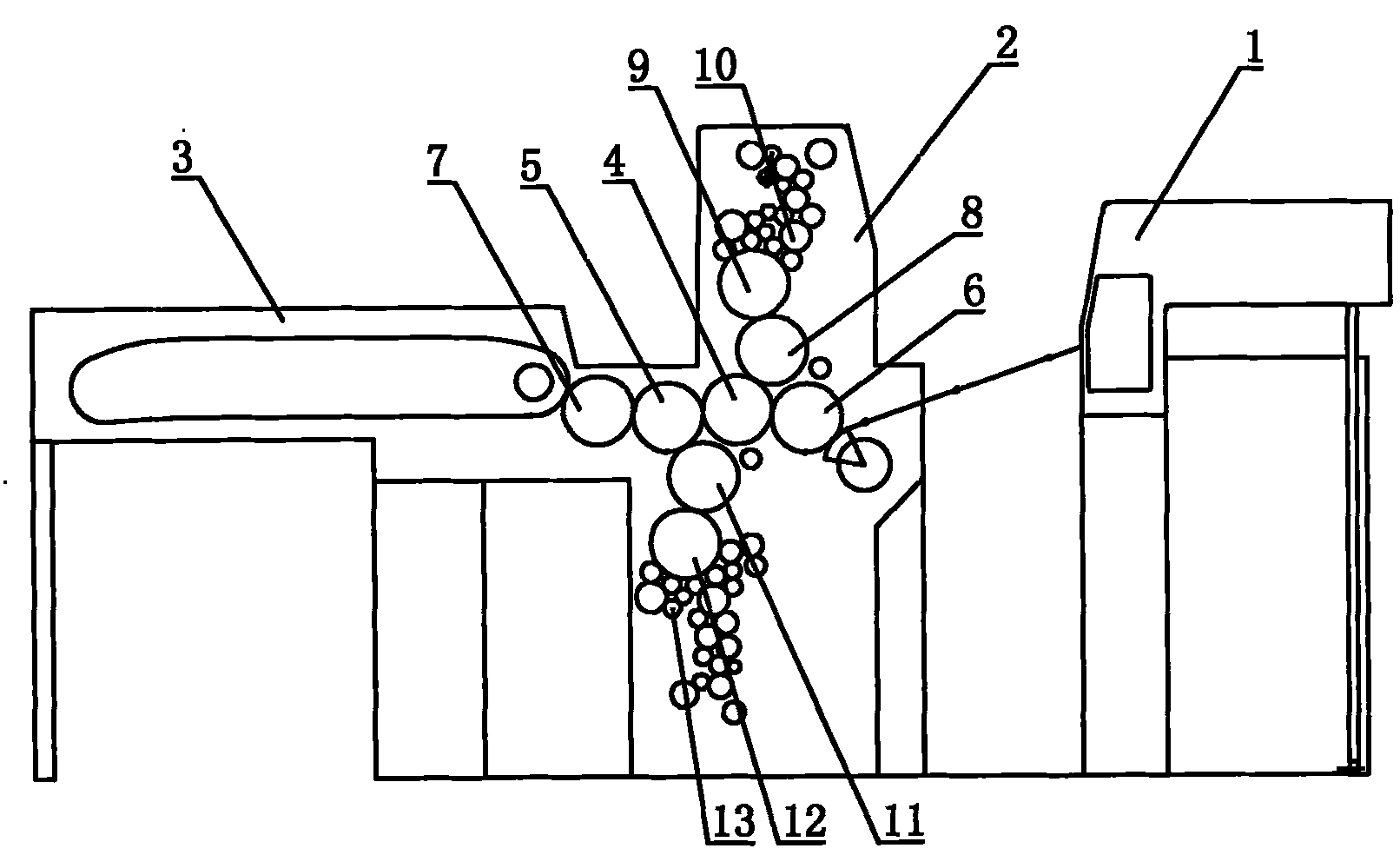

[0007] As shown in the accompanying drawings, the present invention relates to a large folio double-sided offset printing machine, which includes a paper feeding mechanism 1, a printing frame 2, a paper delivery mechanism 3, a front impression cylinder 4, a back impression cylinder 5, and a front paper transfer cylinder. 6. Rear transfer cylinder 7, transfer cylinder I 8, printing plate cylinder I 9, inking unit I 10, transfer printing cylinder II 11, printing plate cylinder II 12 and inking unit II 13.

[0008] The above-mentioned front impression cylinder 4, back impression cylinder 5, front paper transfer cylinder 6, rear paper transfer cylinder 7, transfer printing cylinder I 8, printing plate cylinder I 9, inking device I 10, transfer printing cylinder II 11, printing plate Both the cylinder II 12 and the inking device II 13 are installed on the printing machine frame 2, and the specific structure is: the front impression cylinder 4 and the back impression cylinder 5 are j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com