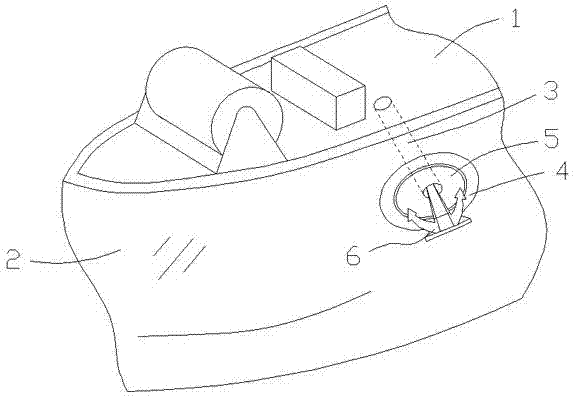

Method for designing and manufacturing circular anchor mouths and right circular conical anchor beds

A manufacturing method and conical surface technology, which is applied in shipbuilding, ship parts, ships, etc., can solve the problems of long processing time, high processing difficulty, unfavorable production activities, etc., and achieve the effect of improving production efficiency and optimizing production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

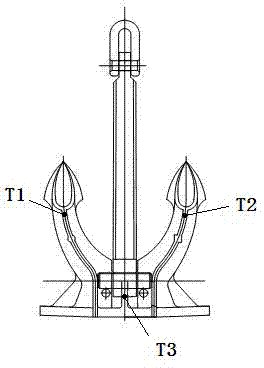

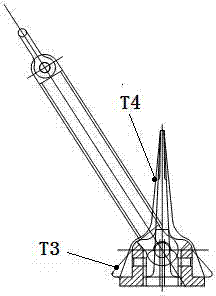

[0066] Embodiment 2: Design and manufacture of the anchor lip 4 of the M-shaped anchor see Figure 6 to Figure 9 , there is no protruding tendon in the middle of the anchor 6, so this kind of anchor 6 is always in contact with the anchor lip 5 through four anchor points. On the left and right anchor teeth below the rotation axis of anchor 6; the other two positioning points M1 and M2 are selected at a certain position on the upper part of the left and right anchor teeth. And M3, M4 should be symmetrically selected on the anchor teeth, generally 30~50mm below the widening part of the anchor teeth. In addition, in order to reduce the bending stress of the anchor teeth, the positioning points M1, M2 of the upper part of the anchor teeth and the positioning points of the lower part of the anchor teeth The distance between points M3 and M4 should not be too large, and at the same time, the design size of the anchor lip 5 is optimized to save costs.

[0067] Since the selected four...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com