Method and device for treating landfill leachate thick water

A landfill leachate and treatment method technology, which is applied in the field of landfill leachate treatment, can solve the problems of reducing the service life of the membrane, affecting the membrane flux, and increasing the salt content of wastewater, so as to improve the service life, reasonable process technology, and smooth operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

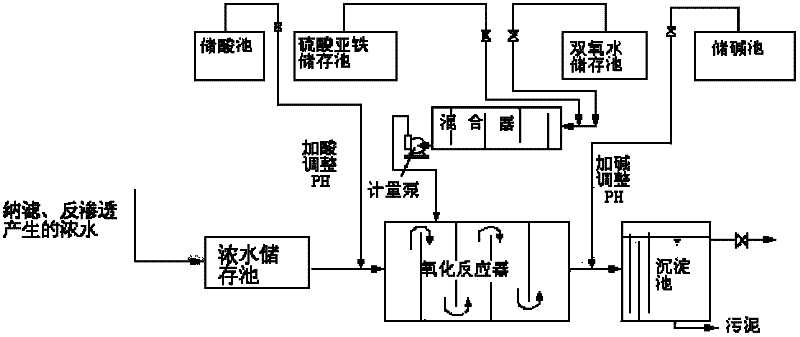

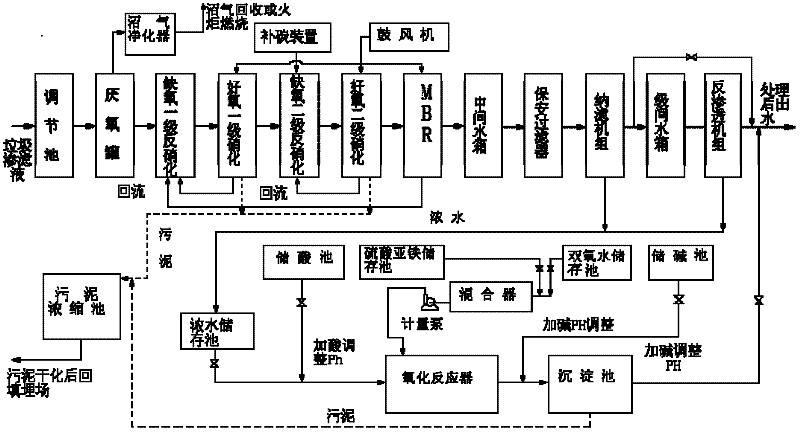

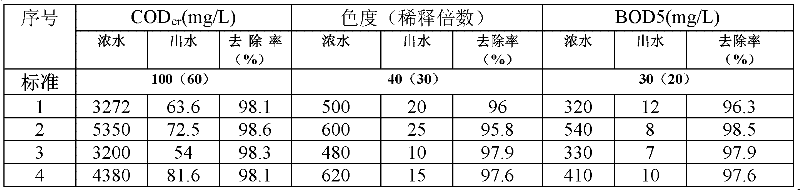

[0052] Embodiment 1, processing the concentrated water produced in the landfill leachate treatment process

[0053] The concentrated water produced in the landfill leachate treatment to be treated in this embodiment is the comprehensive concentrated water that is passed into the concentrated water storage tank respectively from the concentrated water generated in the treatment process of the landfill leachate nanofiltration membrane and the reverse osmosis membrane. The water quality is as follows: COD cr It is 3272mg / L, BOD 5 It is 320mg / L, the chromaticity is 500 times, and the pH value is 6.5.

[0054] This embodiment is carried out in the actual leachate treatment project: the Fenton's reagent used is made of H 2 o 2 and FeSO 4 ·7H 2 Composition of O, H 2 o 2 and FeSO 4 ·7H 2 The molar ratio of O is 3:1.

[0055] Pump out the above-mentioned concentrated water from the concentrated water storage tank at a rate of 625L per hour, pass hydrochloric acid into the pip...

Embodiment 2

[0057] Embodiment 2, processing the concentrated water produced in the landfill leachate treatment process

[0058] The concentrated water produced in the landfill leachate treatment to be treated in this embodiment is the comprehensive concentrated water that is passed into the concentrated water storage tank respectively from the concentrated water generated in the treatment process of the landfill leachate nanofiltration membrane and the reverse osmosis membrane. The water quality is as follows: COD cr It is 5350mg / L, BOD 5 It is 540mg / L, the chromaticity is 600 times, and the pH value is 7.

[0059] This embodiment is carried out in the actual leachate treatment project: the Fenton's reagent used is made of H 2 o 2 and FeSO 4 .7H 2 Composition of O, H 2 o 2 and FeSO 4 .7H 2 The molar ratio of O is 5:1.

[0060] Pump out the above-mentioned concentrated water from the concentrated water storage tank at a rate of 625L per hour, pass hydrochloric acid into the pipe...

Embodiment 3

[0062] Embodiment 3, processing the concentrated water produced in the landfill leachate treatment process

[0063] The concentrated water produced in the landfill leachate treatment to be treated in this embodiment is the comprehensive concentrated water that is passed into the concentrated water storage tank respectively from the concentrated water generated in the treatment process of the landfill leachate nanofiltration membrane and the reverse osmosis membrane. The water quality is as follows: COD cr It is 3200mg / L, BOD 5 It is 330mg / L, the chromaticity is 480 times, and the pH value is 6.5.

[0064] This embodiment is carried out in the actual leachate treatment project: the Fenton's reagent used is made of H 2 o 2 and FeSO4.7H20 composition, H 2 o 2 and FeSO 4 .7H 2 The molar ratio of O is 4:1.

[0065] Pump out the above-mentioned concentrated water from the concentrated water storage tank at a rate of 625L per hour, pass hydrochloric acid into the pipeline lea...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap