Sports washing machine with counterweight and shock absorption function

A washing machine and sports technology, applied in the field of washing machines, can solve the problems of large vibration, high maintenance rate and easy damage of washing machines, and achieve the effects of facilitating maintenance, improving performance and reducing vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

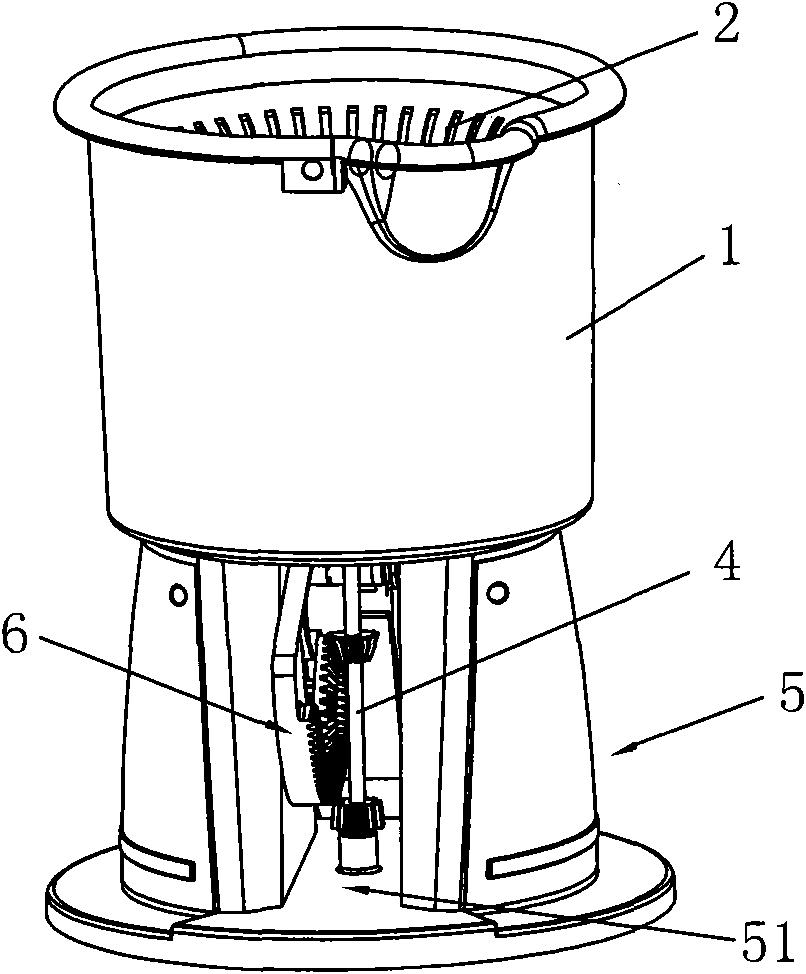

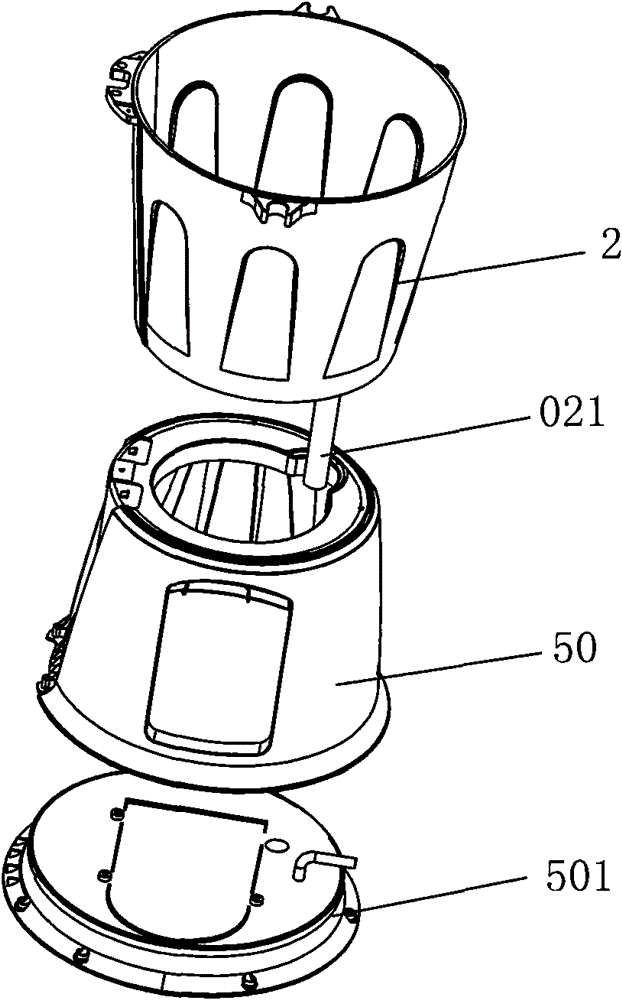

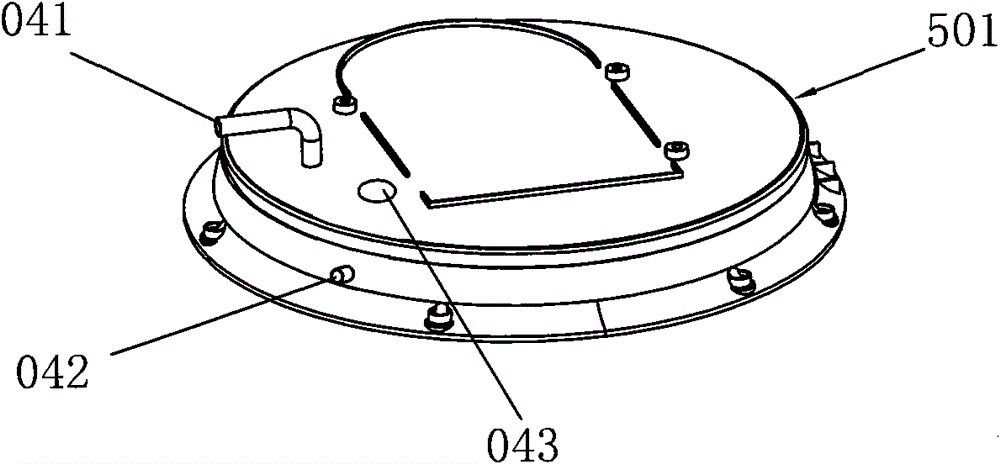

[0046] Such as image 3 , 4 , 5, there is an emptying port 041 and a drain port 042 on the base 501 of the washing machine. The drain port 041 is located on the upper surface of the base, and the drain port 042 is located at the lower end of the base. When the hollow water storage chamber 044 of the base 501 is filled with water, if the drain port 042 is opened, the water in the base can be completely drained .

[0047] The water inlet 043 on the washing machine base 501 communicates with the drain outlet at the bottom of the barrel body 1 through a water inlet pipe 021, so that the water injected into the washing machine barrel body 1 can enter the hollow water storage cavity 044 of the base 501 through the water inlet pipe 021.

[0048] The lower end of the emptying pipe 08 is connected with the emptying port 041, and the upper end can be fixed on the hook 022 outside the washing machine by the hook 081, and the height of the upper end is higher than the maximum water leve...

Embodiment 2

[0054] Such as Figure 6 As shown, the output shaft 4 described in the embodiment of the present invention is fixedly installed with the inner tub 2. Preferably, a pulsator is provided at the bottom of the inner tub 2. The pulsator and the inner tub are integrally structured, and the output shaft drives the inner tub to rotate for both washing and dehydration.

Embodiment 3

[0056] Such as Figure 7 to Figure 9 As shown, a rotatable pulsator 3 is arranged inside the inner barrel 2 according to the embodiment of the present invention, and the output shaft 4 is fixedly connected with the pulsator 3. The bottom of the inner barrel 2 is provided with an inner spline 21, corresponding to the output shaft 4. The outer splines 22, the inner splines 21 and the outer splines 22 are separated during washing, and meshed during dehydration so that the inner tub 2, the pulsator 3 and the output shaft 4 are integrated.

[0057] The output shaft of the sports washing machine of the present invention is provided with a transmission gear, including a washing bevel gear 41 and a dehydration bevel gear 42 arranged on the output shaft 4, and a one-way bearing 43 is arranged between the dehydration bevel gear 42 and the output shaft 4, The washing bevel 41 is located below the dehydration bevel 42, and the distance between the washing bevel 41 and the dehydration beve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com