Safety guaranteeing method and apparatus for vertical ship lift with counterweight

A vertical ship lift and safety assurance technology, applied in the field of ships crossing dams, can solve problems such as increasing the difficulty of operation control, and achieve the effects of convenient operation control, good application prospects, and improved operation safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

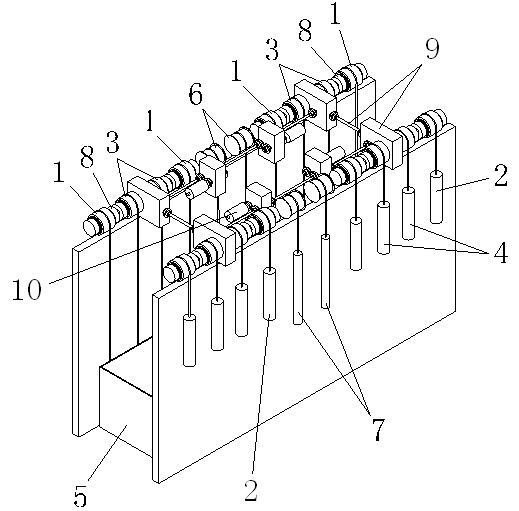

example 1

[0024] Suppose the weight of the ship compartment 5 is 1000 tons, the design weight of the water body in the ship compartment 5 is 2400 tons, 4 fixed pulleys 6 are installed on the vertical lifting frame, and steel wire ropes are all wound on each fixed pulley 6, and one end of the 4 steel wire ropes Connect with the cabin 5 respectively, the other end of each wire rope all connects a gravity weight 7 of 250 tons, and the total weight of 4 gravity weights 7 is equal to the weight 1000 tons of the cabin 5. 8 torque drums 3 are installed on the vertical lifting frame, and steel wire ropes are wound on each torque drum 3. One end of the 8 steel wire ropes is respectively connected with the cabin 5, and the other end of each steel wire rope is connected with a torque drum. Weight 4; 8 safety reels 1 are also installed on the vertical lifting frame, and steel wire ropes are all wound on each safety reel 1, and one end of the 8 steel wire ropes is connected with the cabin 5 respect...

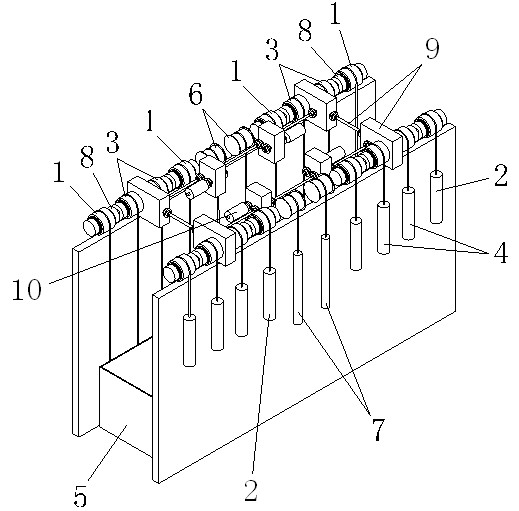

example 2

[0026] Suppose the weight of the ship compartment 5 is 1600 tons, the water body design weight in the ship compartment 5 is 3200 tons, 4 fixed pulleys 6 are installed on the vertical lifting frame, and steel wire ropes are all wound on each fixed pulley 6, and one end of the 4 steel wire ropes Connect with the cabin 5 respectively, the other end of each wire rope all connects a gravity weight 7 of 400 tons, and the total weight of 4 gravity weights 7 is equal to the weight 1600 tons of the cabin 5. 8 torque drums 3 are installed on the vertical lifting frame, and steel wire ropes are wound on each torque drum 3. One end of the 8 steel wire ropes is respectively connected with the cabin 5, and the other end of each steel wire rope is connected with a torque drum. Weight 4; 8 safety reels 1 are also installed on the vertical lifting frame, and steel wire ropes are all wound on each safety reel 1, and one end of the 8 steel wire ropes is connected with the cabin 5 respectively, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com