Equipment for detecting circuit board defects based on visual detection method

A defect detection and visual inspection technology, applied in the direction of optical testing defects/defects, sorting, etc., can solve the problems of inability to meet production, long inspection time, slow inspection speed, etc., to achieve short programming time, fast inspection speed, and adaptability improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings.

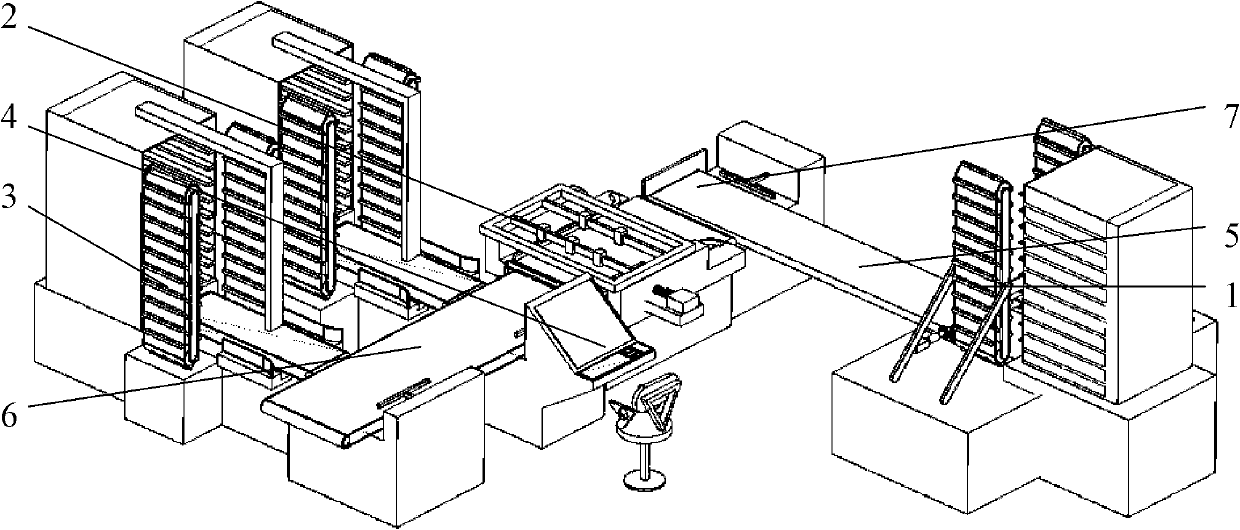

[0026] refer to Figure 1 to Figure 7 , a circuit board defect detection device, comprising a feeding module 1, a detection function module 2, a discharging module 3 and a control module 4, the feeding module is connected with a conveyor belt 5, and the feeding conveyor belt 5 is connected to the circuit board positioning mechanism 7 The detection function module 2 is connected, the detection function module is connected with the discharge module 3 through the discharge conveyor belt 6, and the control module controls the work of all the modules.

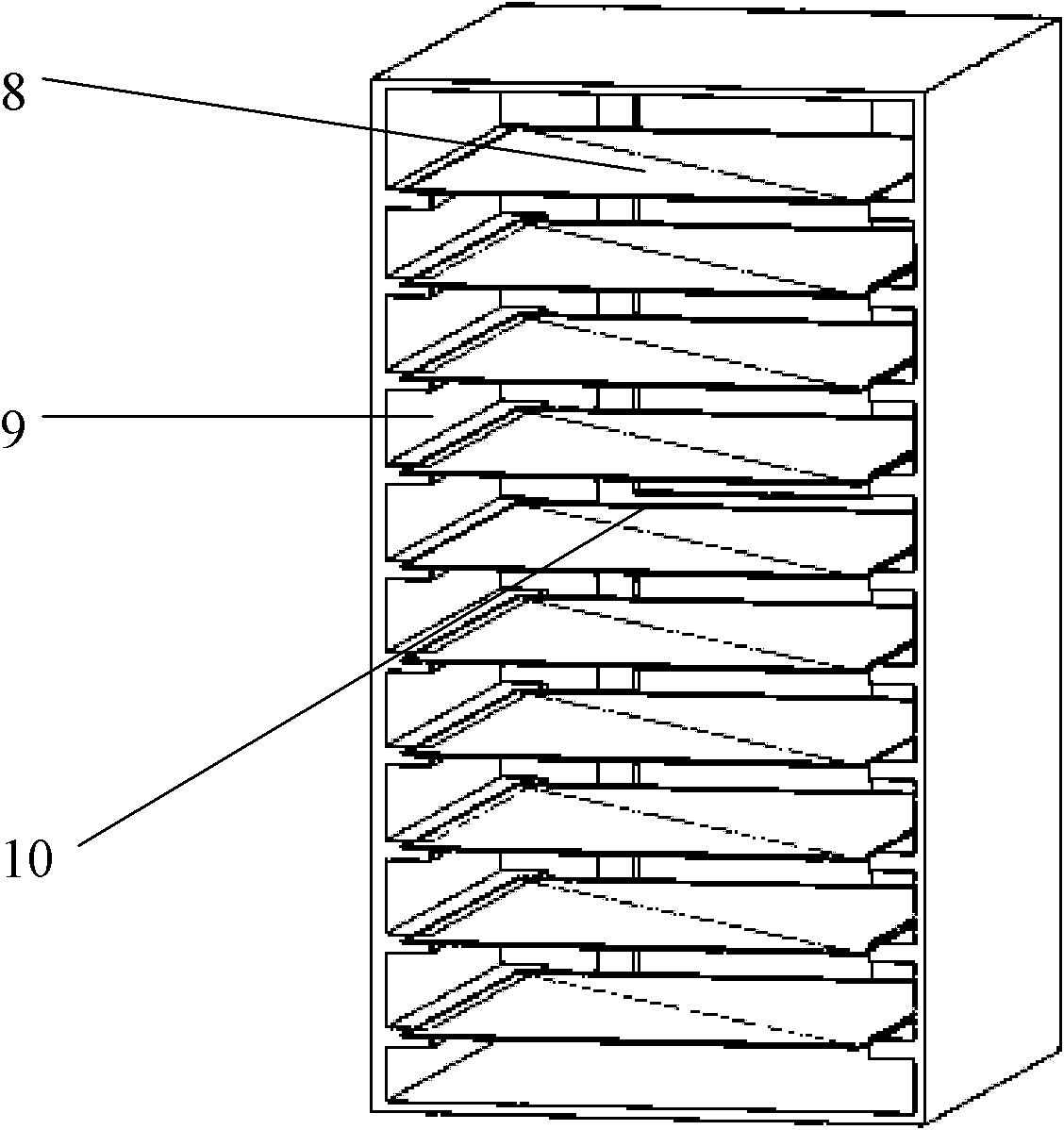

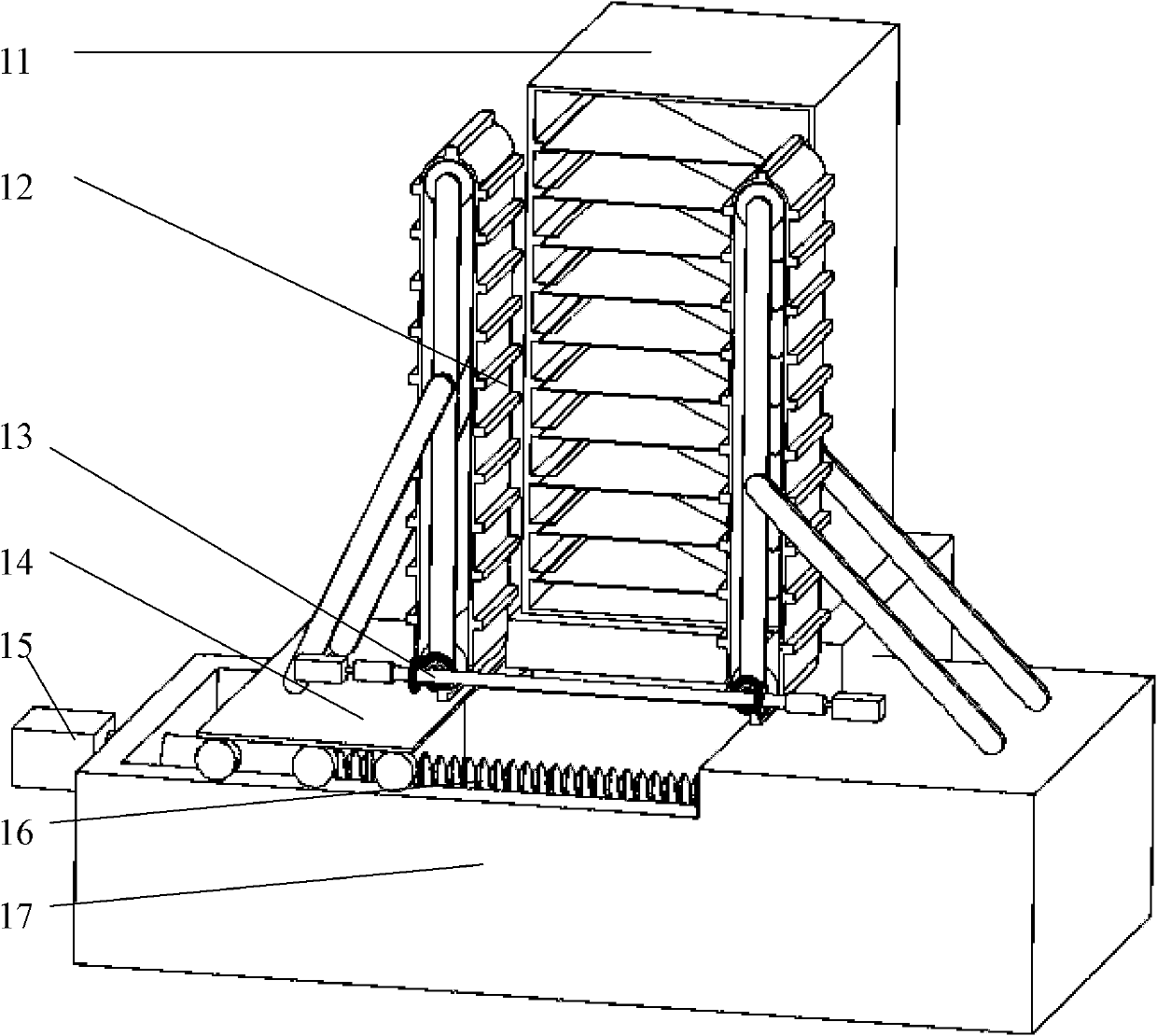

[0027] refer to figure 2 , when the loading frame 11 is fully loaded, it is composed of a loading frame shell 8, a loading frame push rod 9, and a circuit board to be detected 10, and corresponding equidistant material racks are installed on both sides of the inside of the loading frame shell. The push rod of the feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com