Fault detection method for one-class support vector machine based on density parameter optimization

A technology of support vector machine and fault detection, which is applied in computer components, electrical testing/monitoring, testing/monitoring control systems, etc., can solve the problems of not being able to reflect abnormal situations, and it is difficult to obtain abnormal samples, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0050] The inventive method comprises the following steps:

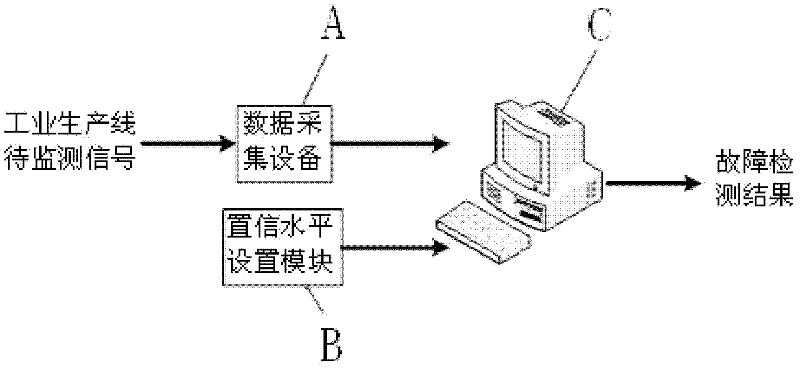

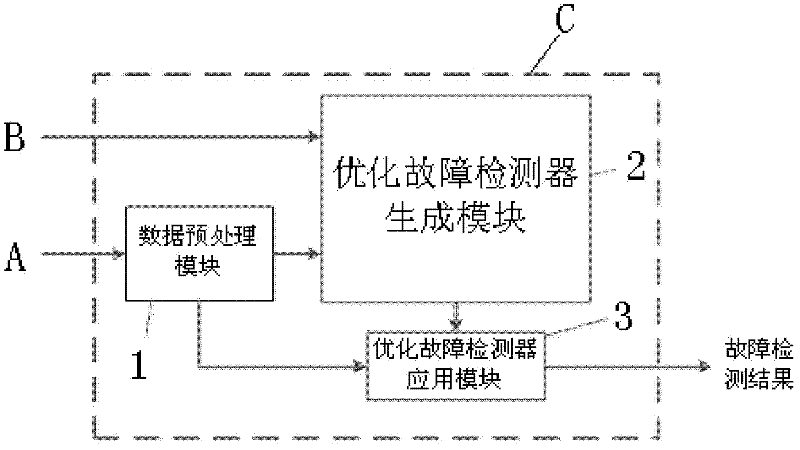

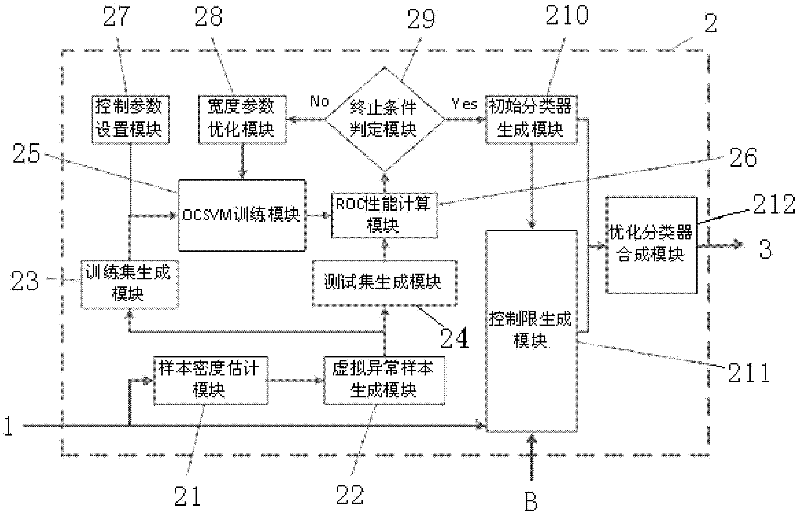

[0051] 1) if figure 1 As shown, a fault detection device including data acquisition equipment A, a confidence level setting module B and a monitoring computer C with a display screen is set up; the input end of the data acquisition equipment A is connected to each monitoring sensor in the industrial production line, and the output end is electrically connected to Monitoring computer C, the output end of confidence level setting module B is connected to monitoring computer C. Such as figure 2 As shown, a data preprocessing module 1 , an optimized fault detector generation module 2 and an optimized fault detector application module 3 are preset in the monitoring computer C. Such as image 3 As shown, the optimized fault detector generation module 2 includes the following submodules: sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com