A kind of cut-off equipment and cut-off method for H-shaped steel production

A technology of H-shaped steel and equipment, which is applied in the field of cutting equipment for H-shaped steel production, can solve the problems of cutting wheel human injury, etc., and achieve the effects of easy replacement, appropriate degree of tightness, and enhanced fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

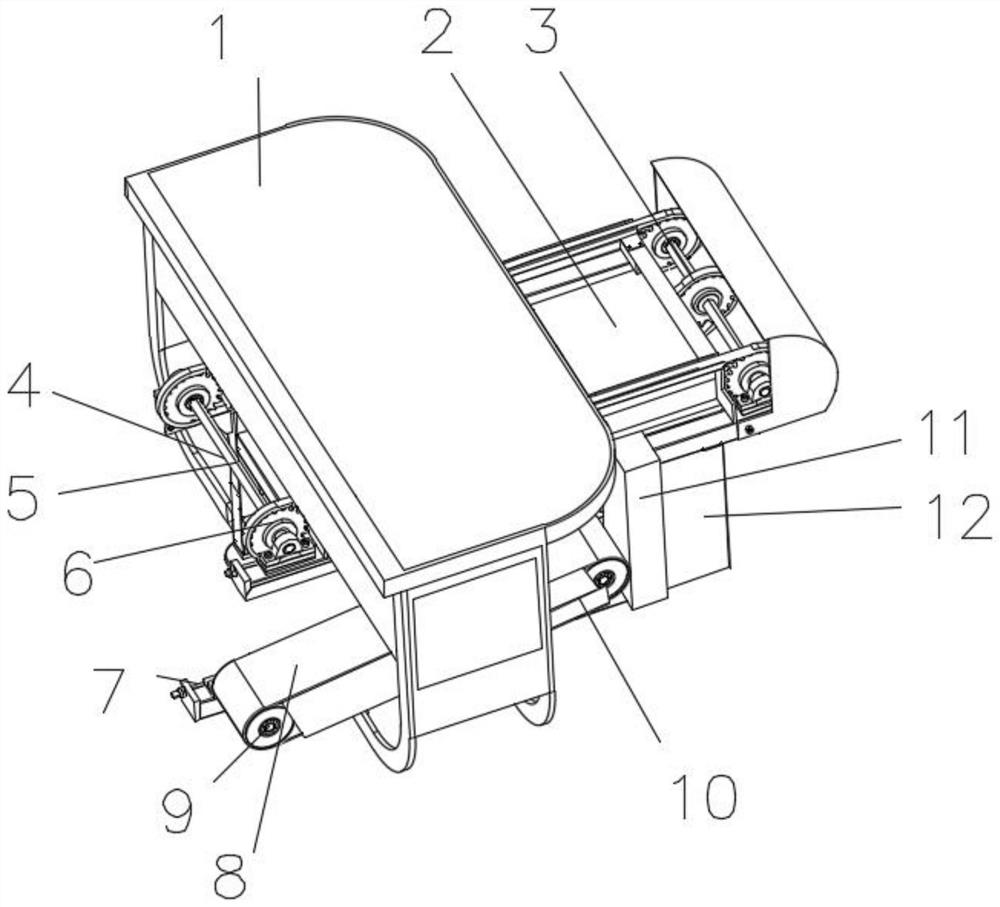

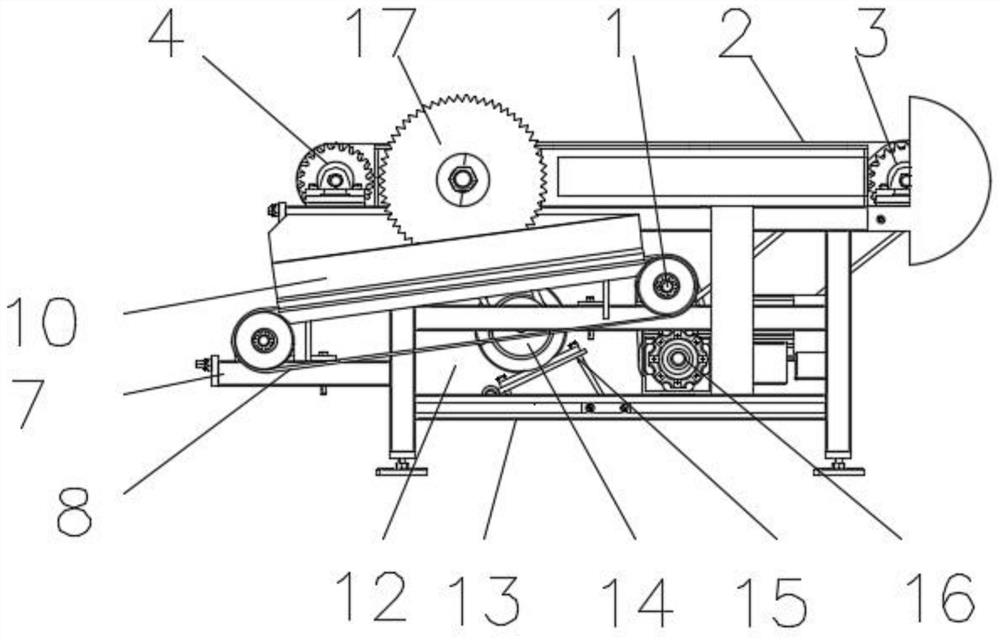

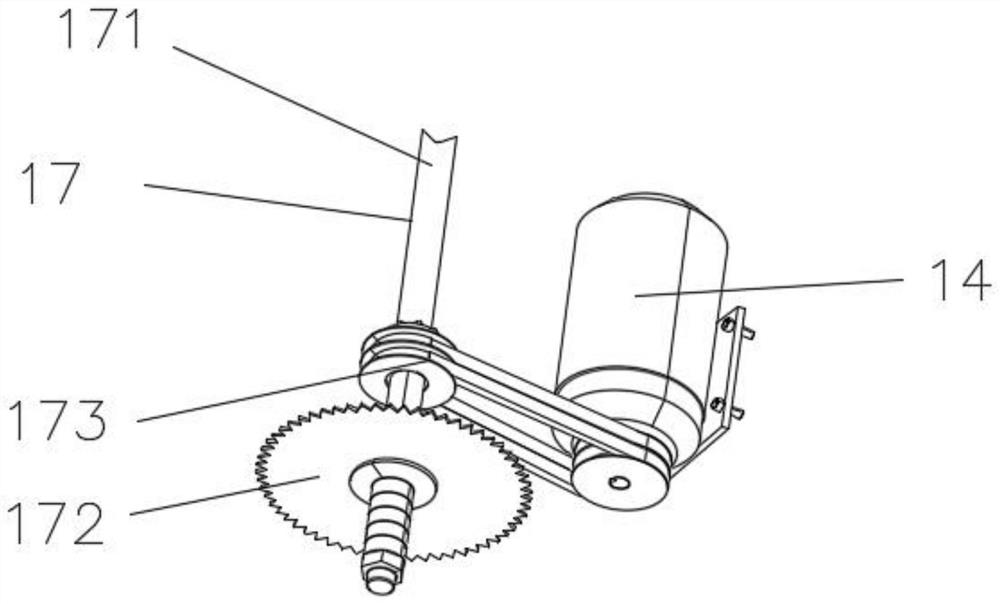

Embodiment 1

[0053] First pass the H-shaped steel workpiece through the steel passing through the window pane set on the J-shaped plate, then start the hydraulic cylinder 105 to drive the H-shaped steel workpiece to rise, fix the H-shaped steel workpiece inside the U-shaped fixed block, and loosen the slider 154 and the bolt between the horizontal plate 13, the slide block 154 slides laterally inside the chute 1 provided on the horizontal plate 13, drives the fixed seat 151 to lift, and then adjusts the tightness of the belt that is socketed on the outer surface of the two pulleys 173 Keep the belt tight, and finally tighten the bolts between the slider 154 and the horizontal plate 13, start the motor one 14, drive the two cutting wheels 172 to rotate, start the motor two 16, drive the shaft two 32 and the gear six 35 Rotate, then drive gear four 33 and shaft three 36 to rotate, and then drive one of the cylinders 9 to rotate and gear seven to rotate, finally drive the driven mechanism two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com