Segment transporting device and shield tunneling machine using same

A technology for a transport device and a segment assembling machine, which is applied in the field of shield tunneling machines, can solve the problems of easily damaged rails, small reserved space for segment assembling, and failure of the segment assembling machine to work normally.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

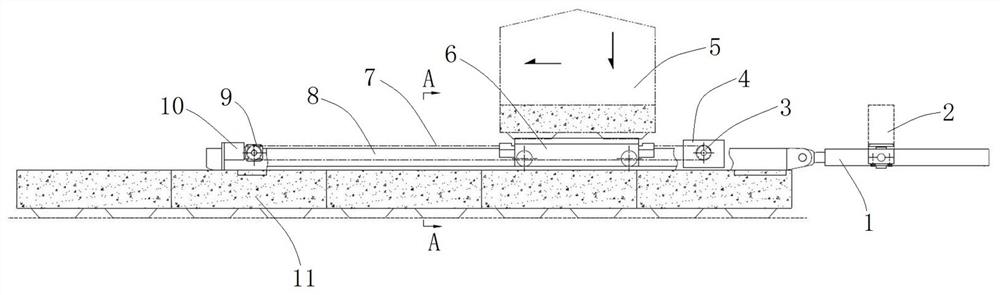

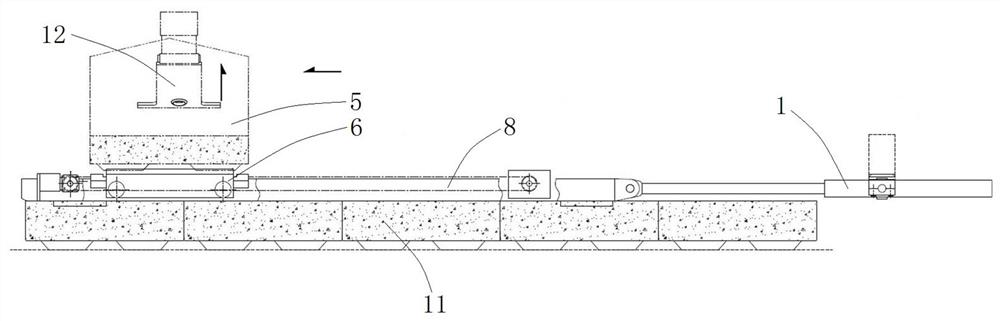

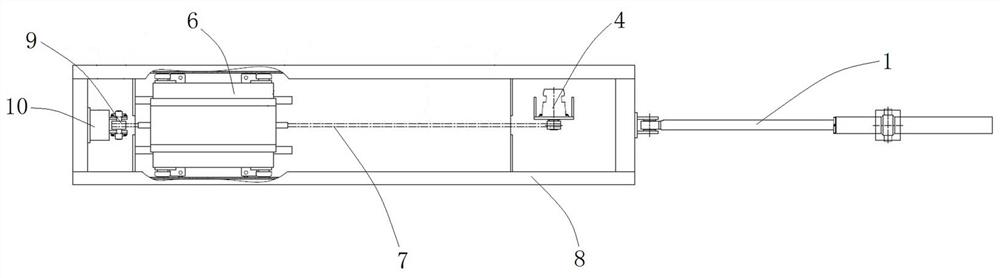

[0046] Such as Figure 1 to Figure 5 As shown, the segment transportation device is arranged between the segment assembly machine and the trailer, and can transport the segment 5 to be transported to the grabbing device 12 of the segment assembly machine, wherein the trailer is connected to the segment assembly machine through a drag cylinder, Move forward step by step with the segment assembly machine.

[0047] For the convenience of description, it is defined that the segment assembly machine, the segment transport device, and the trailer are arranged sequentially from front to back. The segment transport device will transport the segment 5 to be transported forward and return it back without a load. In this embodiment, The segment transport device is arranged on the segment 11 that has been laid. The segment transportation device includes an outer frame 8 placed on the laid segment 11, and the outer frame 8 is a structure with an open top and a closed perimeter and bottom....

specific Embodiment

[0063] The shield machine includes a segment assembly machine and a trailer connected to the rear of the segment assembly machine. The trailer is connected to the segment assembly machine through a drag cylinder, and a segment transportation device between the segment assembly machine and the trailer is installed on the trailer. Wherein, the structure of the segment conveying device is the same as that of the above embodiments of the segment conveying device, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com