Contact image sensor, multi-angle optical characteristic detection method and device

A technology of optical features and detection devices, which is applied in the direction of instruments, character and pattern recognition, and banknote authenticity inspection, etc., can solve the problems of large size of CMOS or CCD camera, affect the recognition effect of color-changing ink, and increase equipment design requirements, etc., to achieve Small size, convenient equipment assembly, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The embodiment of the present invention provides two detection methods of multi-angle optical features, which can detect and identify multi-angle optical features on banknotes, bills or other printed matter.

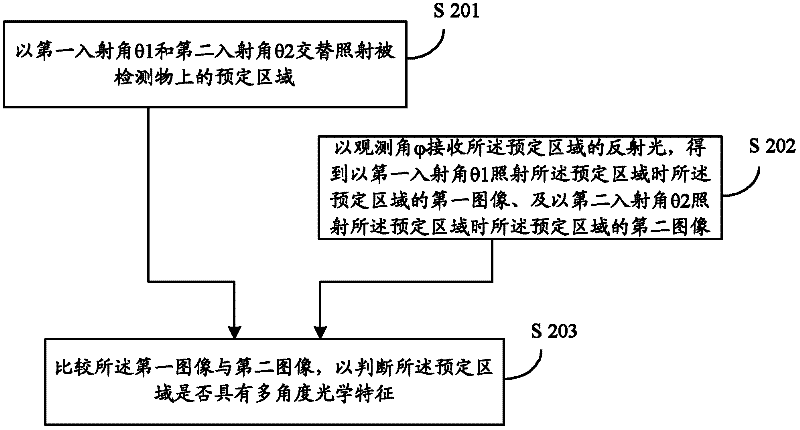

[0062] refer to figure 2 , the first multi-angle optical feature detection method provided in Embodiment 1 of the present invention includes the following steps:

[0063] S201. Alternately irradiate a predetermined area on the object to be detected with a first incident angle θ1 and a second incident angle θ2; the first incident angle θ1 and the second incident angle θ2 are not equal.

[0064] S202. Receive the reflected light of the predetermined area at the observation angle φ, and obtain the first image of the predetermined area when the predetermined area is irradiated with the first incident angle θ1, and when the predetermined area is irradiated with the second incident angle θ2 A second image of the predetermined area.

[0065] The above-mentioned first ...

Embodiment 2

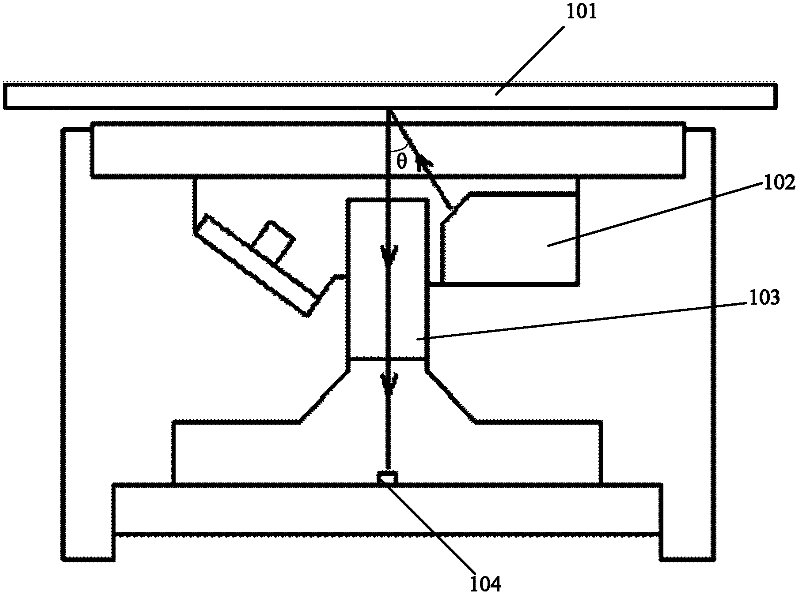

[0080] Figure 4 It is a schematic structural diagram of the multi-angle optical feature detection device provided in Embodiment 2 of the present invention.

[0081] Such as Figure 4 As shown, the multi-angle optical feature detection device includes a CIS and a recognition unit ( Figure 4 Not shown in ), wherein the CIS includes alternately lit light sources 302a, 302b, lenses 303 and photoelectric conversion chips 304.

[0082] The light source 302a and the light source 302b are arranged on both sides of the lens 303 .

[0083] The light source 302a illuminates a predetermined area on the object to be detected 301 at a first incident angle θ1 when turned on.

[0084] The light source 302b illuminates a predetermined area on the object to be detected 301 at the second incident angle θ2 when turned on.

[0085] In the second embodiment, the first incident angle θ1 and the second incident angle θ2 are not equal.

[0086] In order to enable the predetermined area on the d...

Embodiment 3

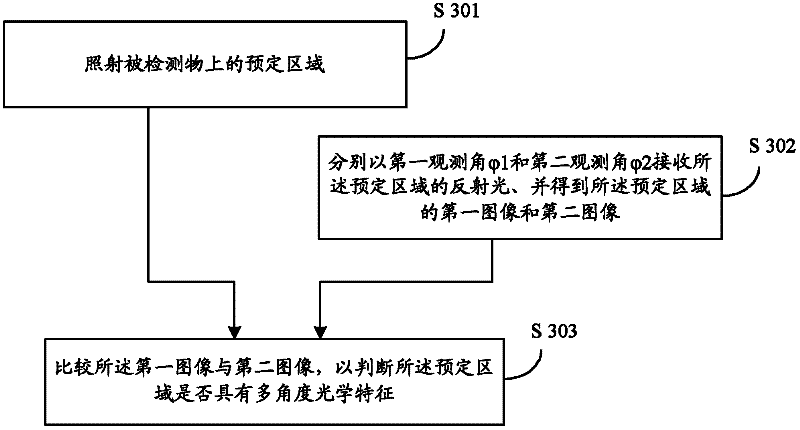

[0093] Figure 5 It is a schematic structural diagram of another multi-angle optical feature detection device provided in Embodiment 3 of the present invention.

[0094] Figure 5 The difference between the shown CIS and the multi-angle optical feature detection device in Embodiment 2 is that in the multi-angle optical feature detection device provided in Embodiment 3, the two light sources 402a and 402b in the CIS are arranged on the same side of the lens 403, The lens 403 receives the reflected light in a predetermined area at an observation angle φ, and guides it into the photoelectric conversion chip 404, where the observation angle φ is greater than 0 degrees, that is, the lens 403 and the photoelectric conversion chip 404 are arranged obliquely to the plane of the detected object 401 .

[0095] The two light sources 402a and 402b are installed on the same side of the lens 403, which allows the lens 403 to have a certain inclination angle, so that the light reflected by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com