Beam type two-way pushing frame-assembling machine

A technology of two-way jacking and framing machine, which is applied in the direction of sustainable manufacturing/processing, electrical components, climate sustainability, etc. It can solve problems such as poor processing technology, increased misalignment of profile meshes, and unstable battery panel positions. , to achieve the effect of high machining precision and meet the requirements of dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

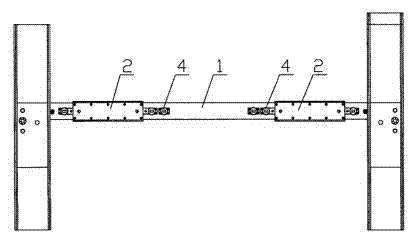

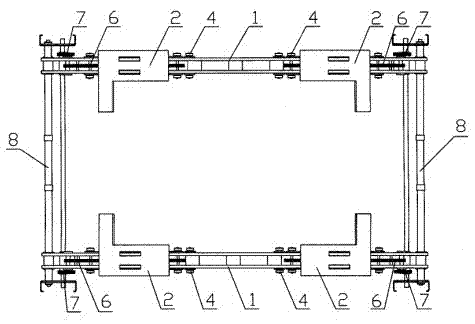

[0016] Such as Figure 1~4 As shown, a beam-type two-way pushing frame machine includes a basic frame composed of two elastic beams 1 and two sets of optical axes 8, and each set of optical axes 8 passes through one end of the elastic beam 1 respectively. For the through hole, the elastic beam 1 can move on the optical axis 8, and the optical axis 8 is installed on the peripheral frame. The pushing module 2 is provided with a U-shaped groove 3 inside the pushing module 2, and the combined bearing 4 matching the U-shaped groove 3 is arranged on the side of the elastic beam 1, and the pushing module 2 is connected with the driving motor through a transmission mechanism.

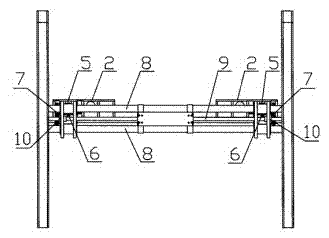

[0017] Such as image 3 , 4 As shown, there are two optical axes 8 in each g...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap