Electric connector

A technology for electrical connectors and connecting grooves, which is applied in the direction of connection, circuit, fixed/insulated contact components, etc., and can solve problems such as inability to plug in two directions, damage to USB sockets, and difficulty in productization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

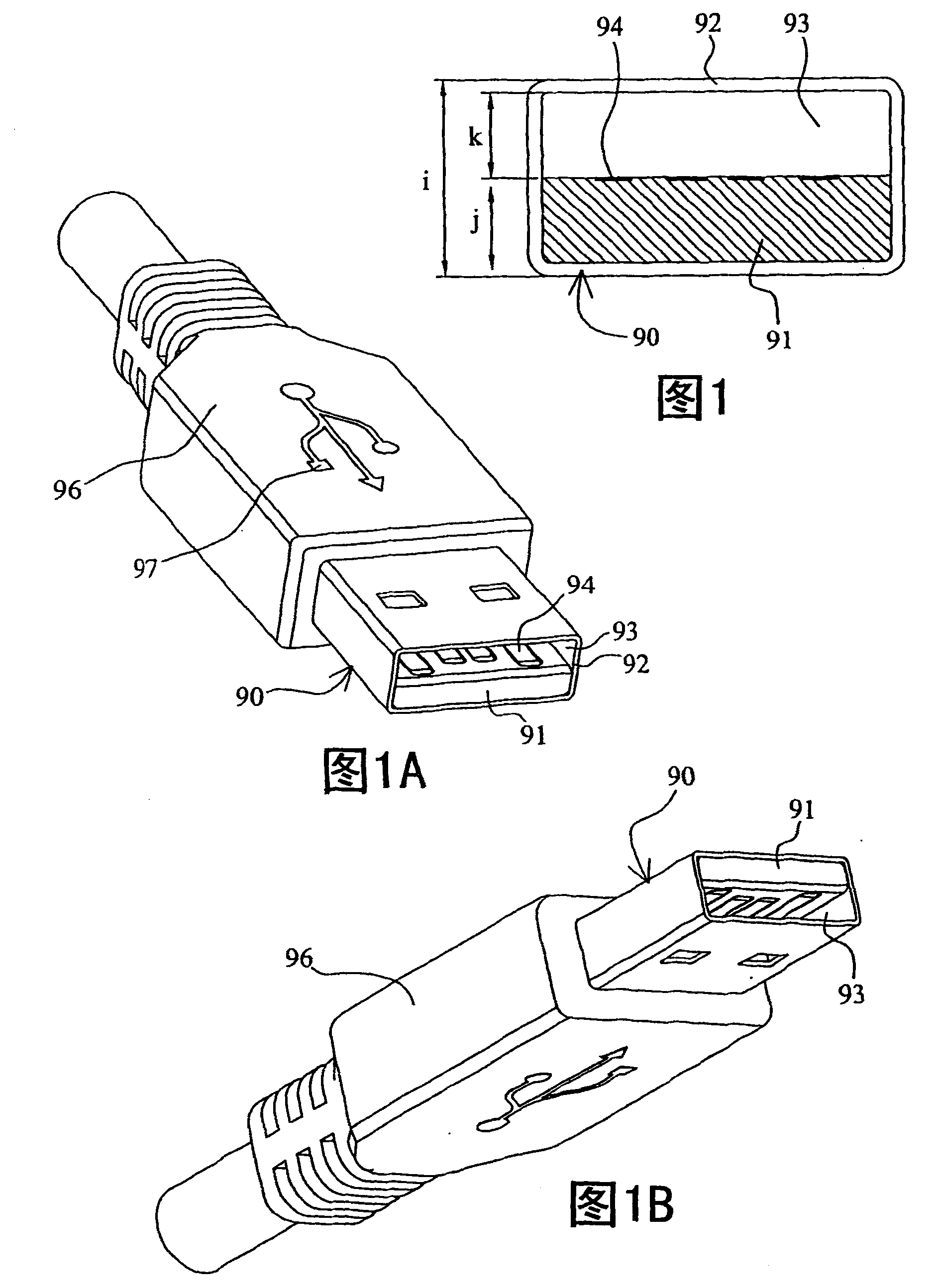

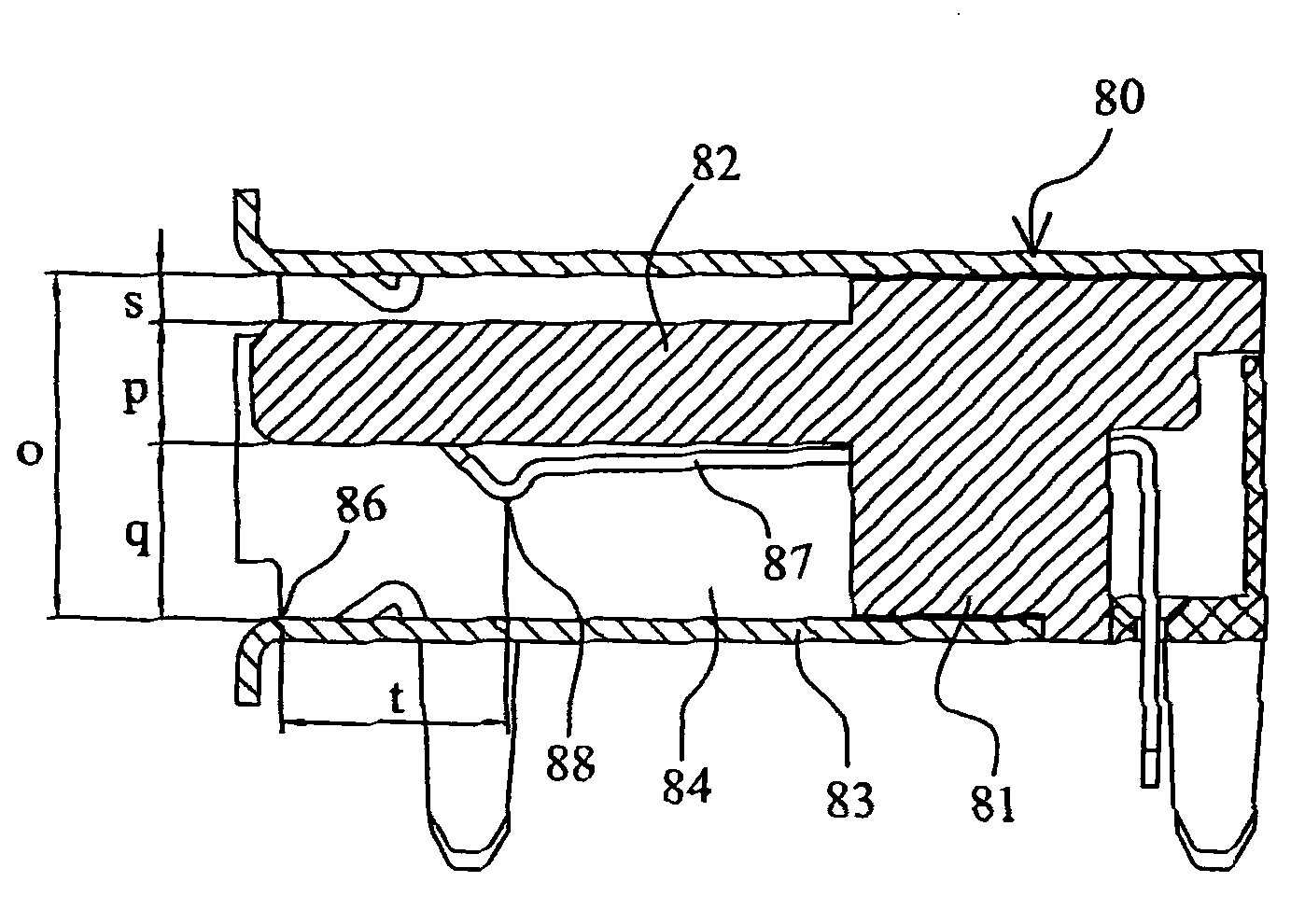

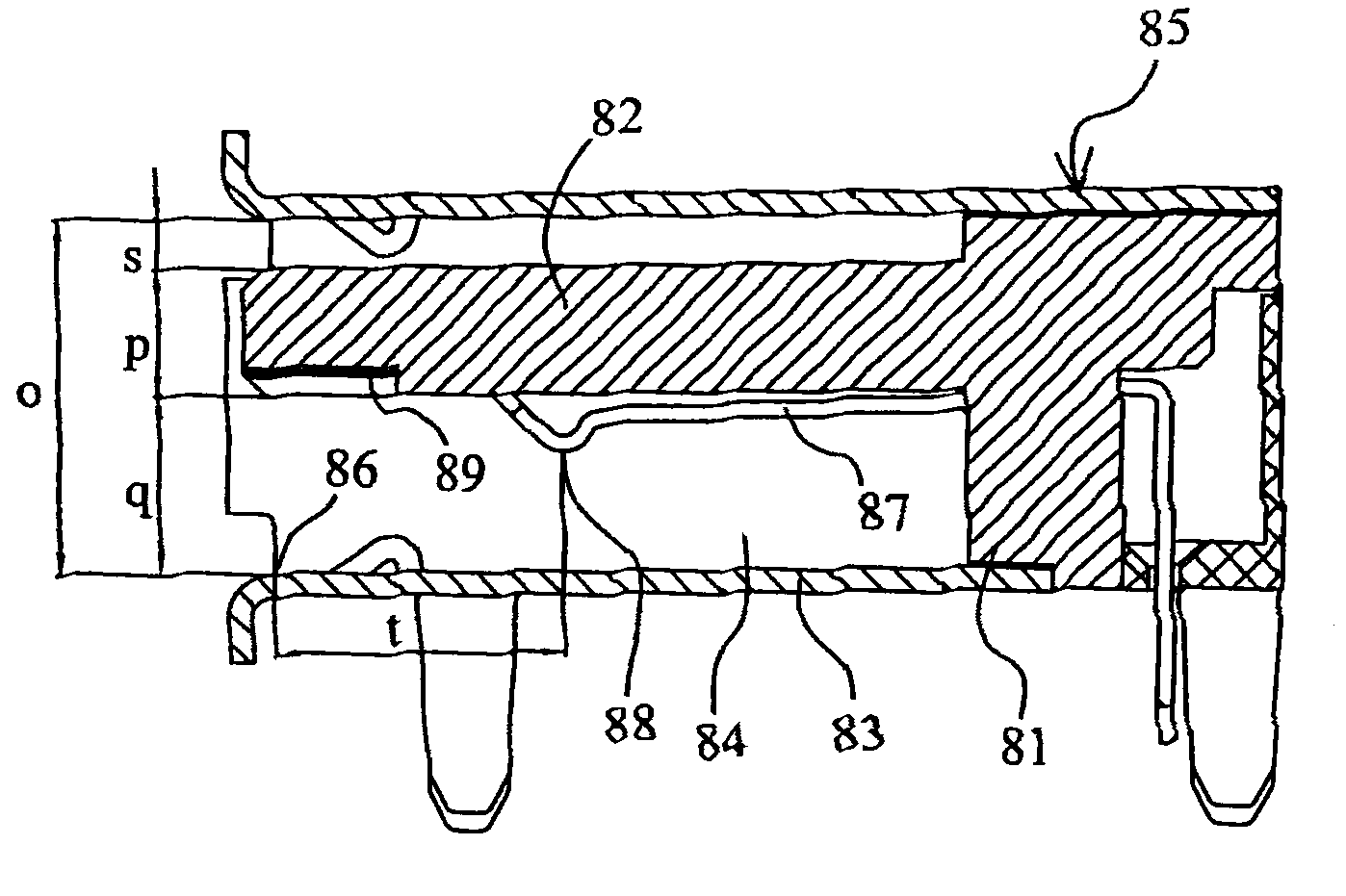

[0071] see image 3 , Figure 4 ,and Figure 5 , is the first embodiment of the present invention, which is a USB2.0 socket, which can be connected to the aforementioned USB2.0 male head 90, which includes a plastic seat 10, a tongue piece 20, a metal shell 30 and two rows of first Terminal 40, where:

[0072] The tongue 20 protrudes integrally at the front end of the plastic seat 10. The front end is thinner and the rear end is thicker. It is tapered from front to back, so that the tongue is firm and not easy to break.

[0073] A connecting groove 31 is formed in the metal shell 30, the metal shell 30 is arranged on the front end of the plastic seat 10 and covers the tongue piece 20 inside, the top surface and the bottom surface of the rear section of the connecting groove 31 are provided with a concave surface 32, so that The height of the back section of the connection groove 31 is larger than that of the insertion opening, and the front end of the connection groove 31 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com