Power battery module

A power battery and module technology, applied in the field of electric vehicle battery module design, can solve the problems of inability to accurately control the battery, poor cooling and fire extinguishing effect, and loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below.

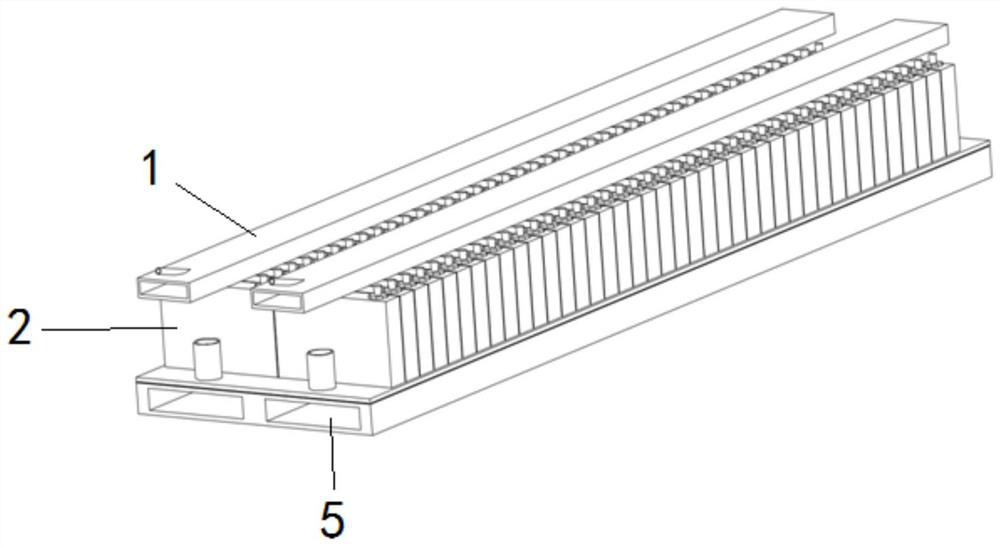

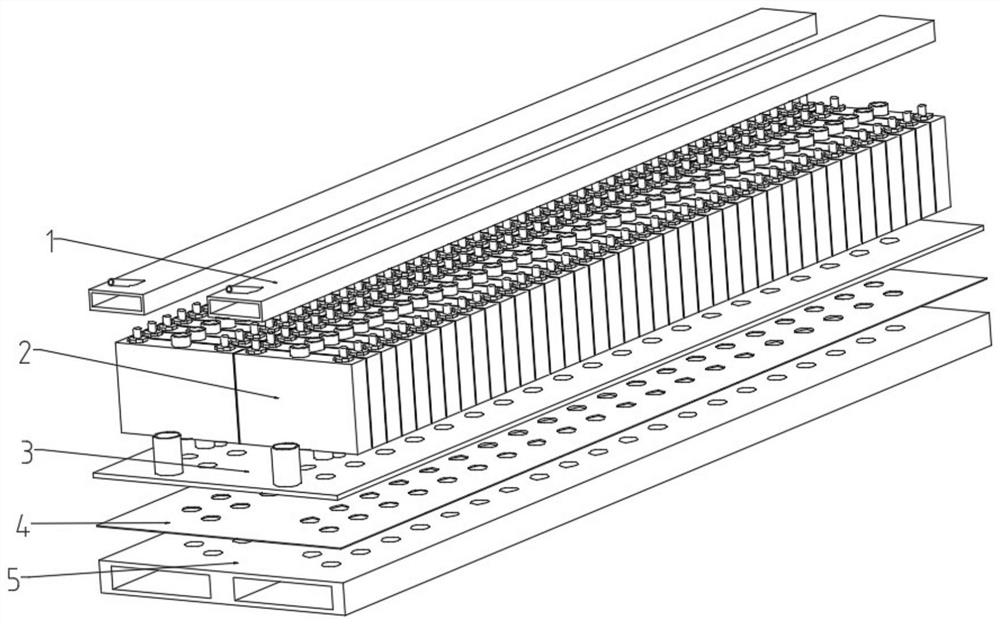

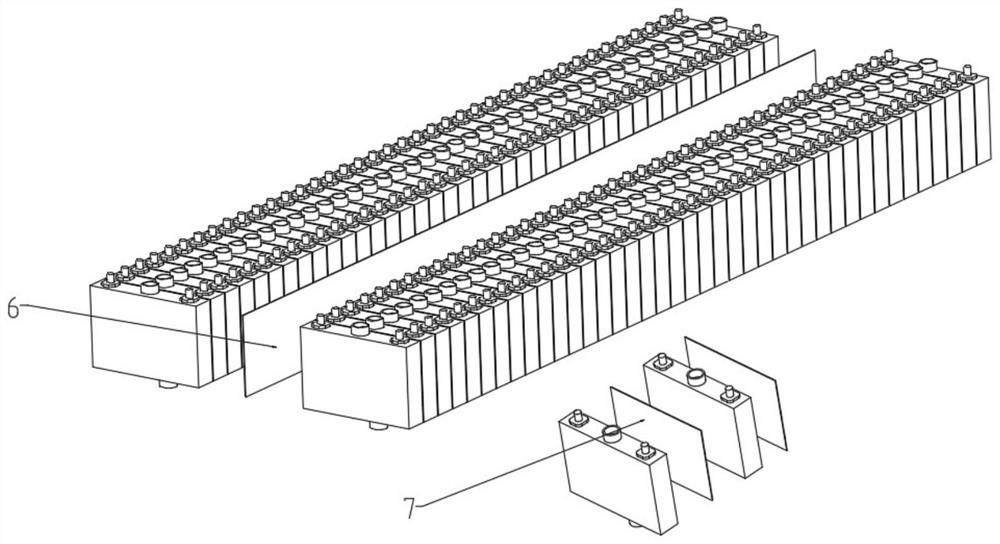

[0033] Such as Figure 1 ~ Figure 3 , Figure 5 , Figure 8 ~ Figure 10 As shown, a power battery module includes a top ventilation pipe 1 and a plurality of single cells 2, each of which is equipped with a top pressure relief valve 10, and the upper end of each top pressure relief valve 10 is connected to a Safety valve 13, the top ventilation pipe 1 is arranged above the safety valve 13, the upper end of the safety valve 13 communicates with the lumen of the top ventilation pipe 1, the top ventilation pipe 1 is provided with a sensing device and a coolant injection device, the sensing device is connected with A control device, the control device controls the action of the coolant spraying device.

[0034] Specifically, the top ventilation duct 1 serves as a channel for exhausting smoke above the unit battery 2 and a channel for injecting fire-fighting coolant. Its main structure is a rectangular duc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com