Device for measuring precision cold rolling thickness of single plate

A thickness measurement and precision technology, which is applied in the field of thickness measurement devices for precision cold rolling of single sheets, can solve the problems of low automatic control precision and rarely install thickness gauges, etc., and achieve the effect of accurate thickness measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

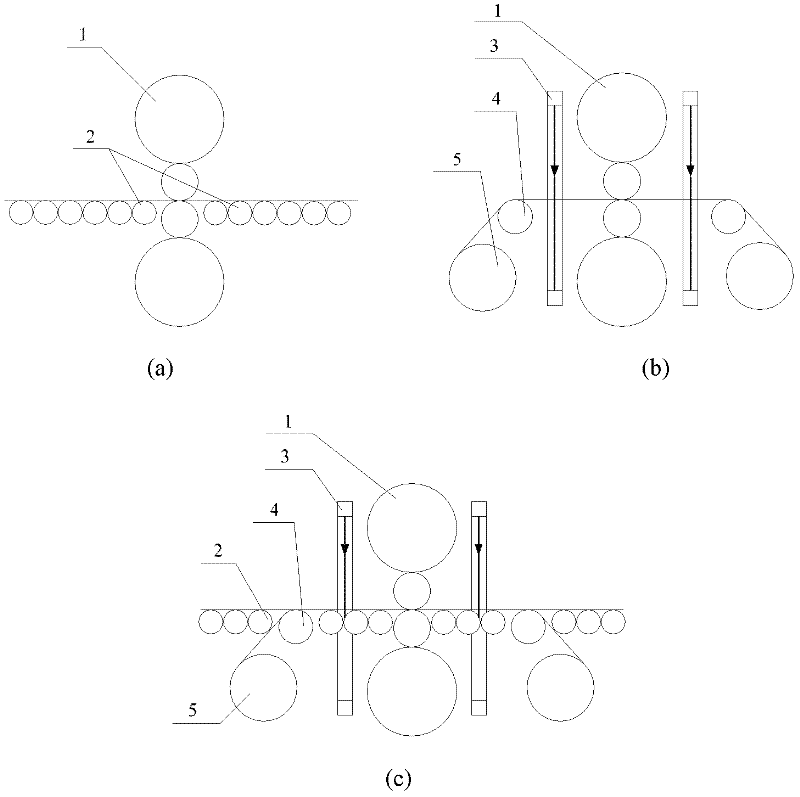

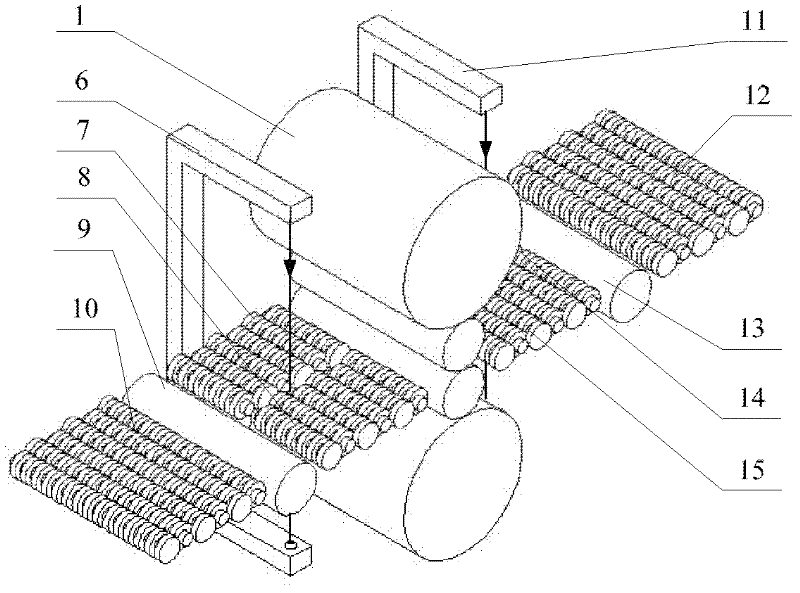

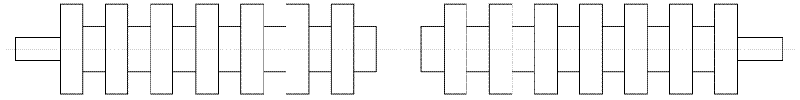

[0019] A precision cold-rolled plate thickness measuring device for a single sheet, the device includes: a four-roll or six-roll reversing cold rolling mill 1, a front thickness gauge 6, a rear thickness gauge 11, an outer machine front roller table 10, an outer machine The rear roller table 12, the internal machine front roller table, the internal machine rear roller table, the front turning roller 9, and the machine rear turning roller 13; along the rolling direction, the outer machine front roller path 10, the machine front turning roller 9, The front roller table of the internal machine, the four-high or six-high reversing cold rolling mill 1, the rear roller table of the internal machine, the turning roll 13 behind the machine, and the rear roller table 12 of the external machine; the front roller table of the internal machine and the rear roller table of the internal machine are respectively located In the envelope of the C-frame of the front and rear thickness gauges, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com