A small/micro pulsator washing machine

A pulsator-type, washing machine technology, applied in the field of washing machines, can solve the problems of large space occupied by the shock absorbing device, and the structure is not easy to shrink, and achieve the effects of saving fixed parts, reducing mechanical devices, and reducing centrifugal force and vibration force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

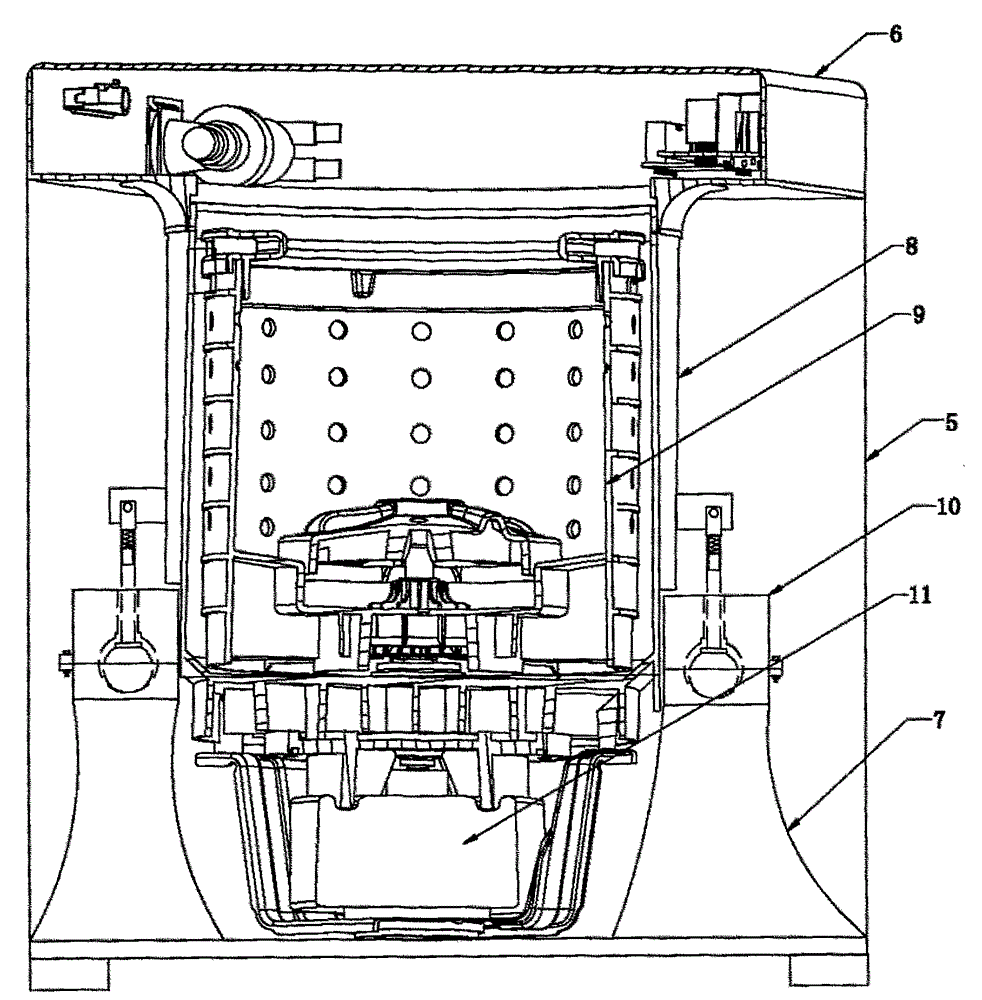

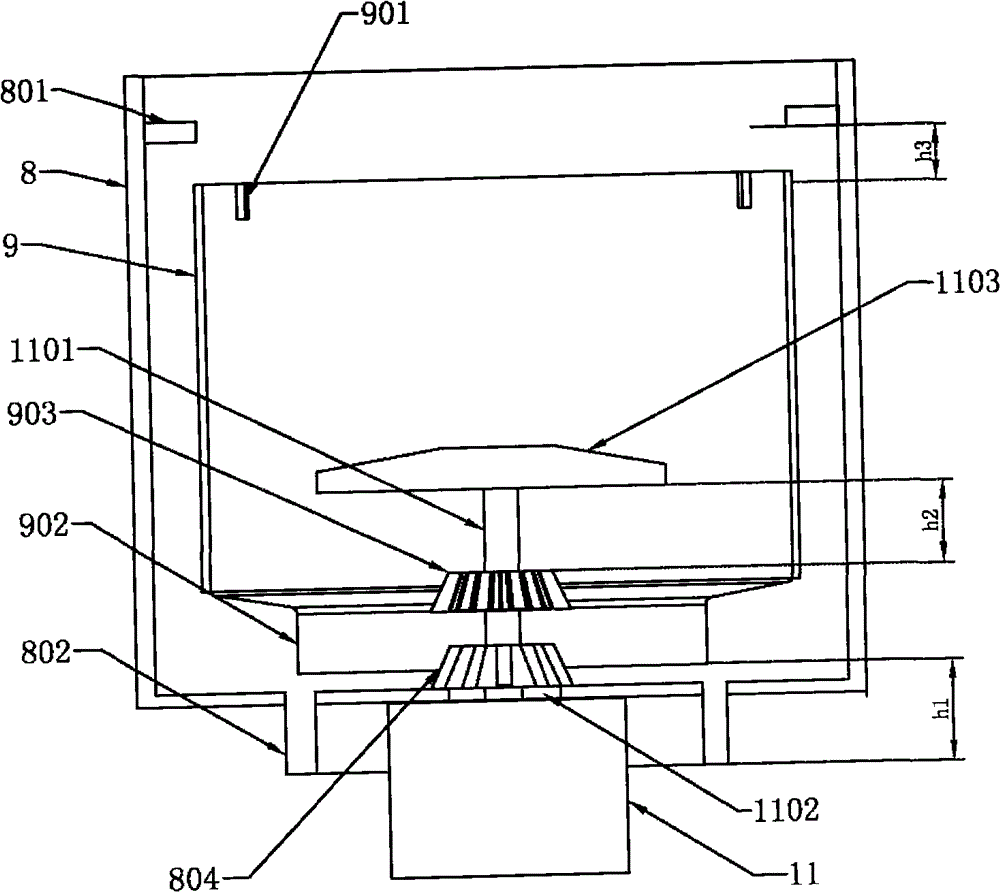

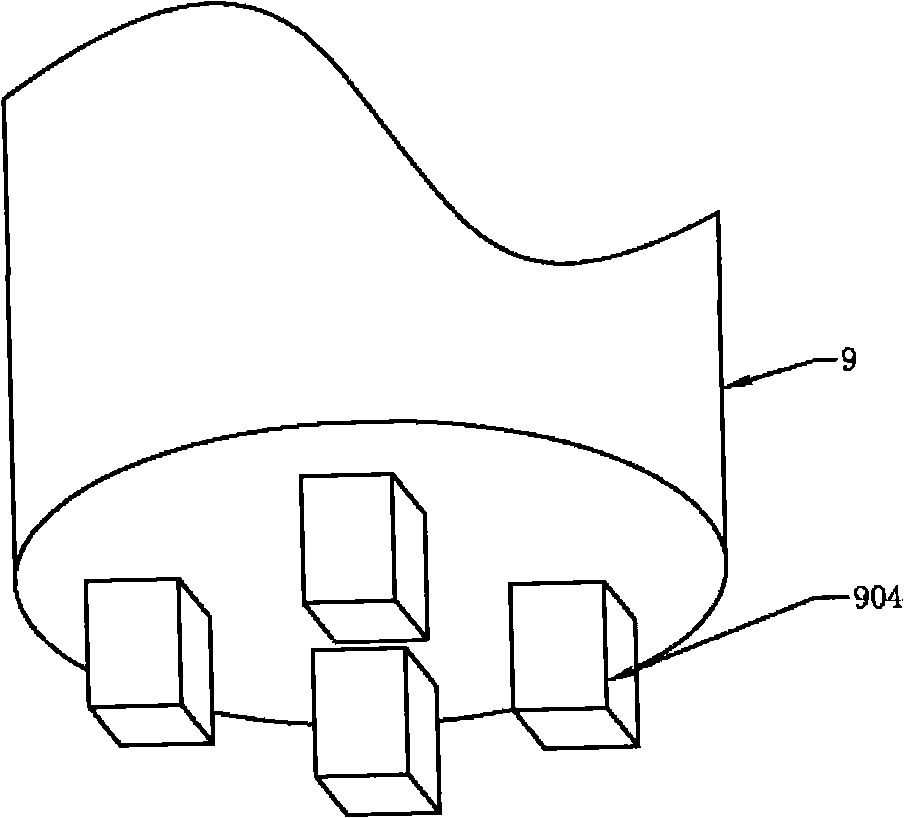

[0041] Example 1: When installing a small / miniature pulsator washing machine, install four sliding damping devices symmetrically between the washing machine box and the outer tub, first turn the small / miniature washing machine upside down, and connect the four outer tub connectors The two symmetrical arms on the connecting arm are fixed on the relative position of the outer barrel through pin shafts, the lower members of the four receiving seats are fixed on the base, and the cylinders of the four intermediate movable parts pass through the upper members of the receiving seats. After the hollow channel is inserted into the shock absorbing tube of the corresponding outer tub connector, the lower member and the upper member of the receiving seat are fixed together with bolts, and then the receiving seat and the base of the washing machine are fixed to complete the installation of a washing machine.

Embodiment 2

[0042] Embodiment 2: Another installation method of a small / miniature pulsator washing machine, install four sliding shock absorbers symmetrically between the washing machine cabinet and the outer tub, first turn the small / miniature washing machine upside down, and place the four outer tubs The two symmetrical arms on the connecting arm are fixed on the relative position of the outer barrel through the pin shaft, the left member of the four receiving seats is fixed on the base, and the cylinders and balls of the four middle movable parts are snapped into the left member Then buckle the right component of the receiving seat to the left component, enclose the cylinder and balls in the spherical cavity and hollow channel inside, and then fix the left component and the right component together with bolts to complete the installation of a washing machine .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com