Self-formed ball seat sliding sleeve

A technology of ball seat type and sliding sleeve, which is applied in the direction of wellbore/well components, earthwork drilling, sealing/packing, etc. It can solve the problem of large sliding sleeve, achieve low accident rate, easy to use, and avoid misoperation of pitching Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

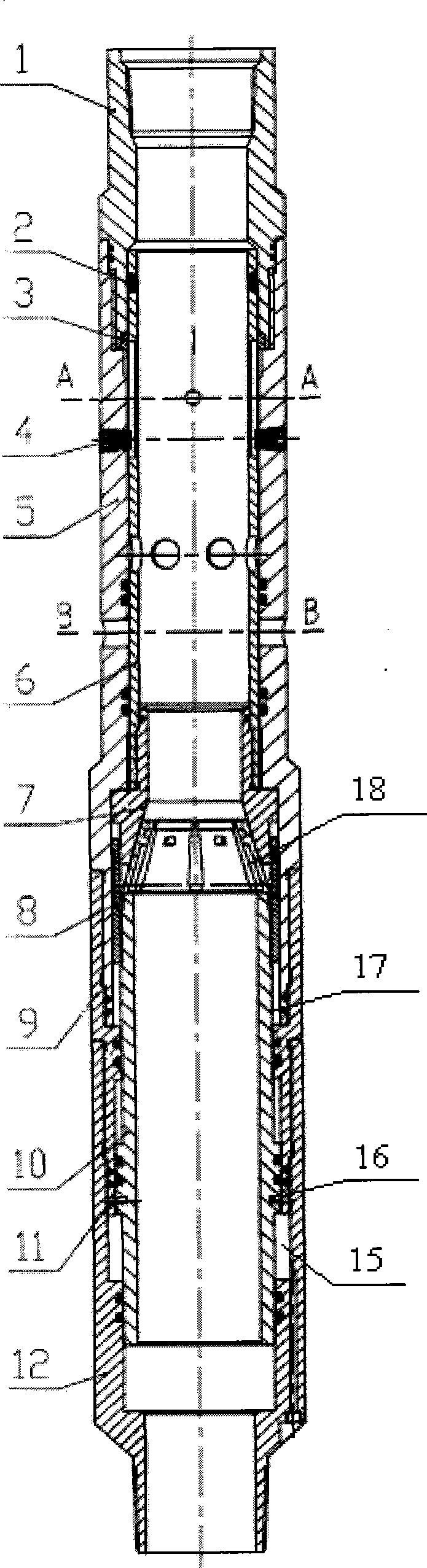

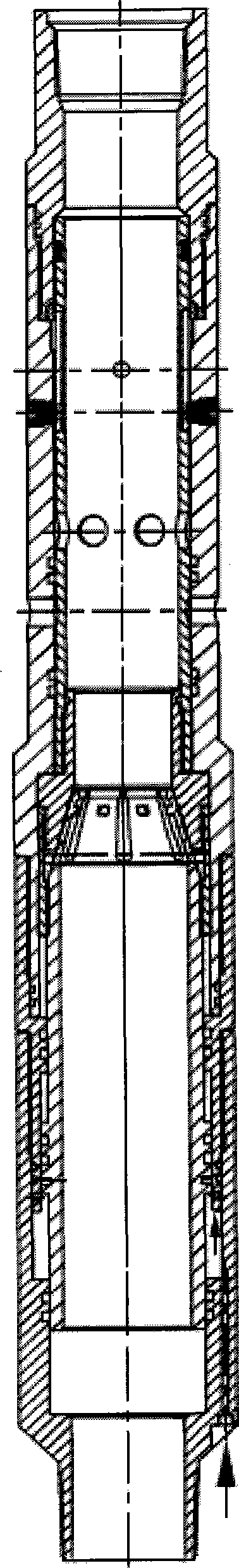

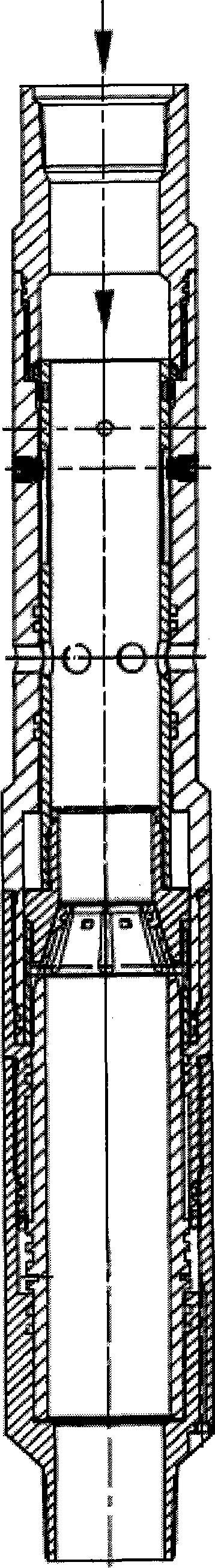

[0021] Such as Figure 1 The shown upper joint 1, split ring 2, retaining ring 3, plug-type sliding key 4, sliding key groove 13, outer cylinder 5, sliding sleeve 6, ball seat 7, self-locking sleeve 8, fixed sleeve 9, sliding mandrel 10. The way in which the shear pin 11 and the lower joint 12 are connected together completes the process of automatically generating the ball seat.

[0022] The specific working process is: connecting the upper joint 1 with the outer cylinder 5, the connecting sleeve 9, and the lower joint 12 in sequence to form the outer cover of the automatic ball seat; the internal structure has a sliding sleeve 6, a ball seat 7, a self-locking sleeve 8 and Sliding mandrel 10, one end of sliding sleeve 6 is inserted into the upper joint, and the other end is threadedly connected with ball seat 7. The claw at the front end of sliding mandrel 10 snaps into the bell mouth of ball seat 7, and connects with connecting sleeve 9 with shear pin 11 To be fixed together...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com