Energy-saving fan-series model for circulating fluidized bed boiler

A circulating fluidized bed and boiler technology, applied in the direction of mechanical equipment, machines/engines, liquid fuel engines, etc., can solve the problems of high motor power, low maximum efficiency, and lost opportunities for bidding, and achieve small dynamic pressure difference, The effect of easy processing and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

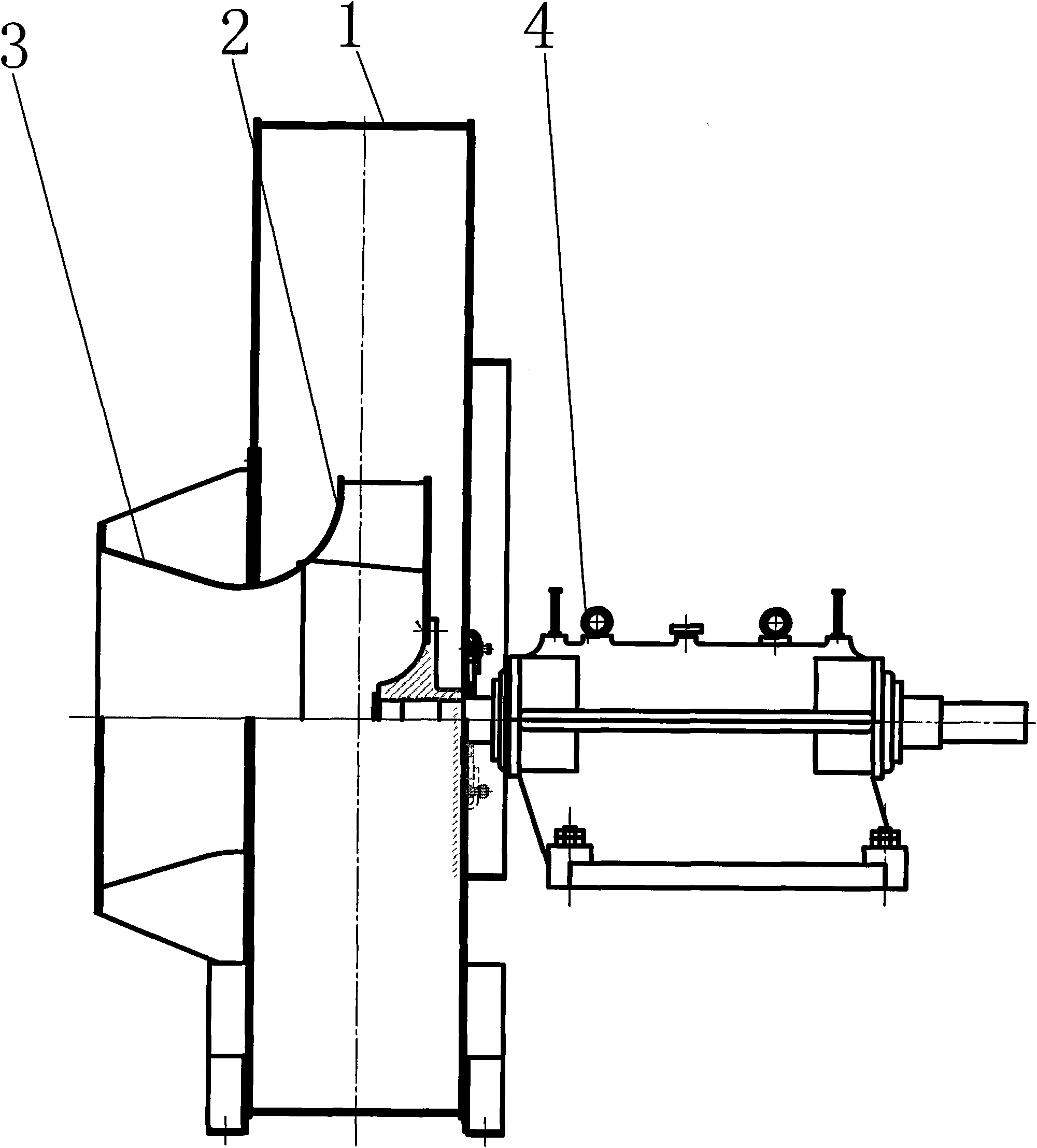

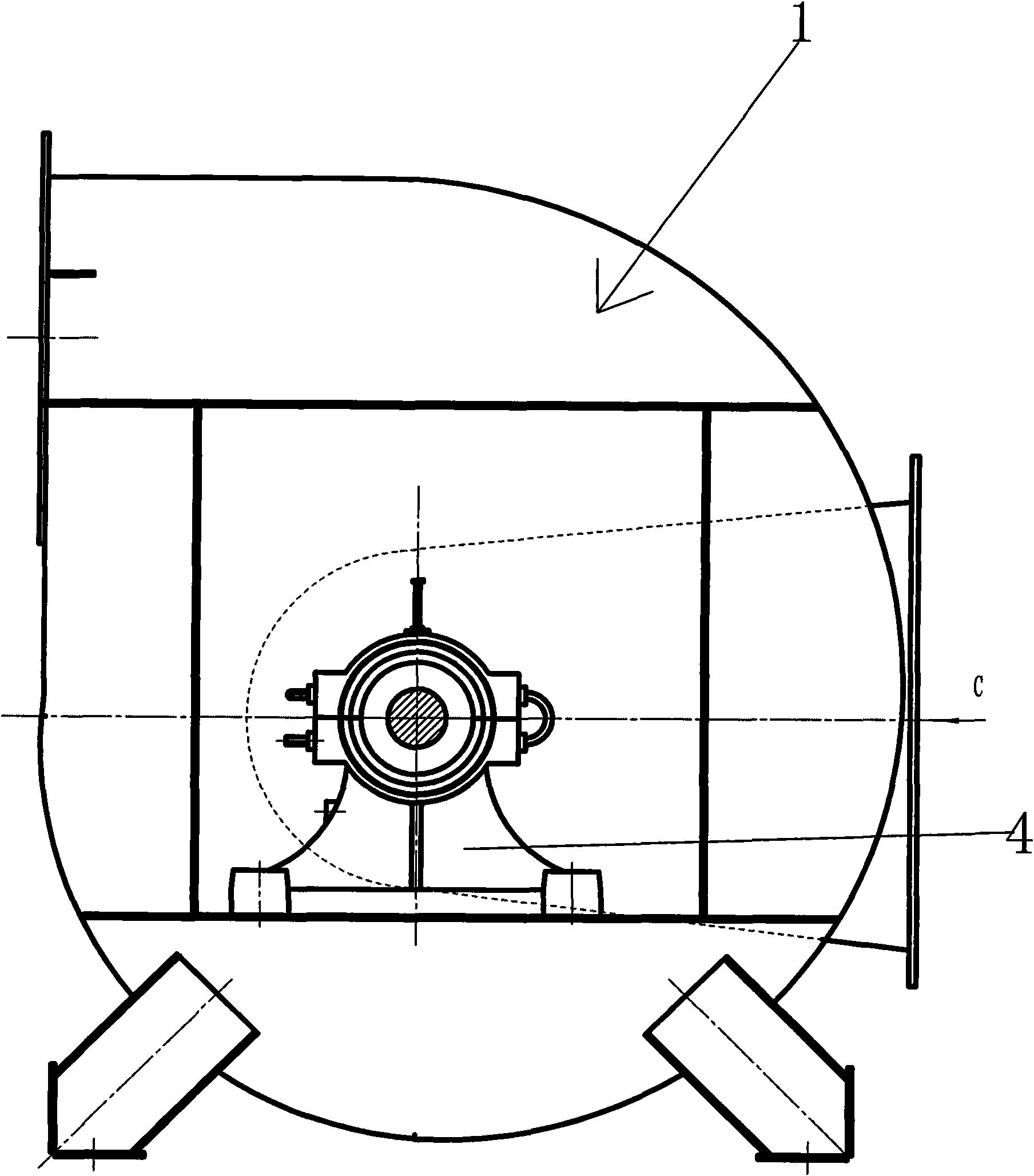

[0031] A series model of a circulating fluidized bed boiler energy-saving fan, including a casing 1, an impeller 2, an air inlet 3 and a transmission group 4. The transmission group includes a main shaft, a bearing box, etc., which is a known technology.

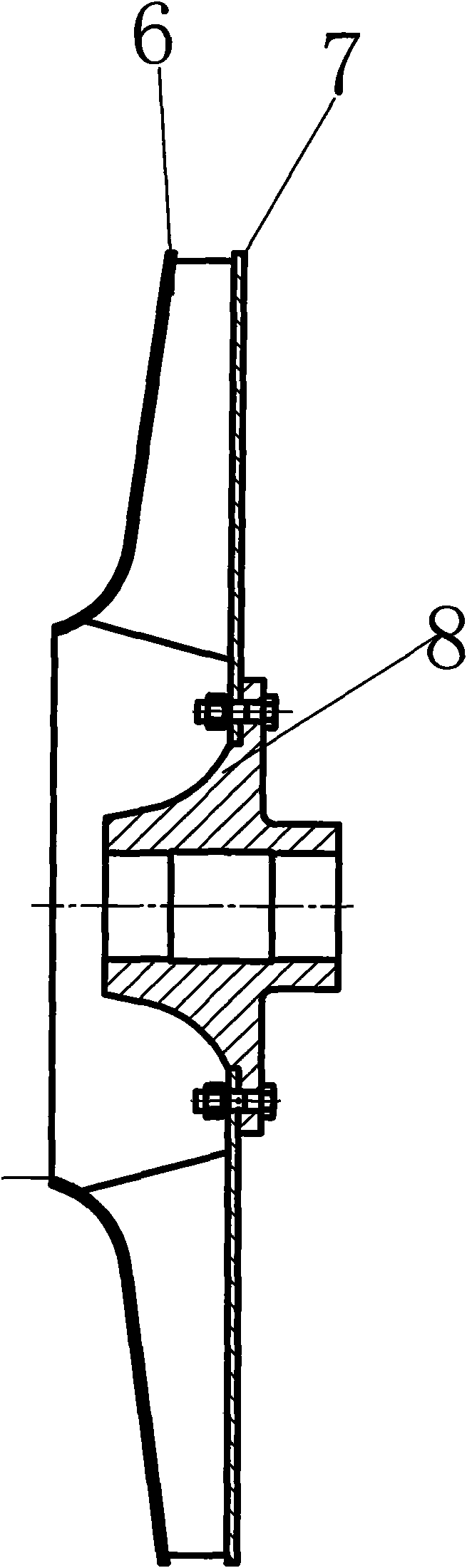

[0032] The impeller is composed of 16 backward plate-shaped blades 5, an arc-shaped wheel cover 6, a flat disc 7 and a hub 8. 16 backward plate-shaped blades 5 are evenly distributed along the circumferential direction, and are welded between the arc-shaped wheel cover 6 and the flat-shaped wheel disc 7, and assembled with the hub 8. The casing is a volute made of plates welded, the air inlet 3 is a welded structure, and its profile is a conical arc that converges in the axial direction.

[0033] The outlet diameter of the impeller 2 is 880 mm, the blade outlet diameter is 800 mm, the inlet diameter is 389 mm, the width is 151.9 mm, the outlet width is 77.5 mm, and the blade outlet angle is 68°.

[0034] The air inlet 3 has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com