Design method of seven-segment type straight claw rotor

A design method, seven-stage technology, applied in computing, special data processing applications, instruments, etc., can solve problems such as high precision and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

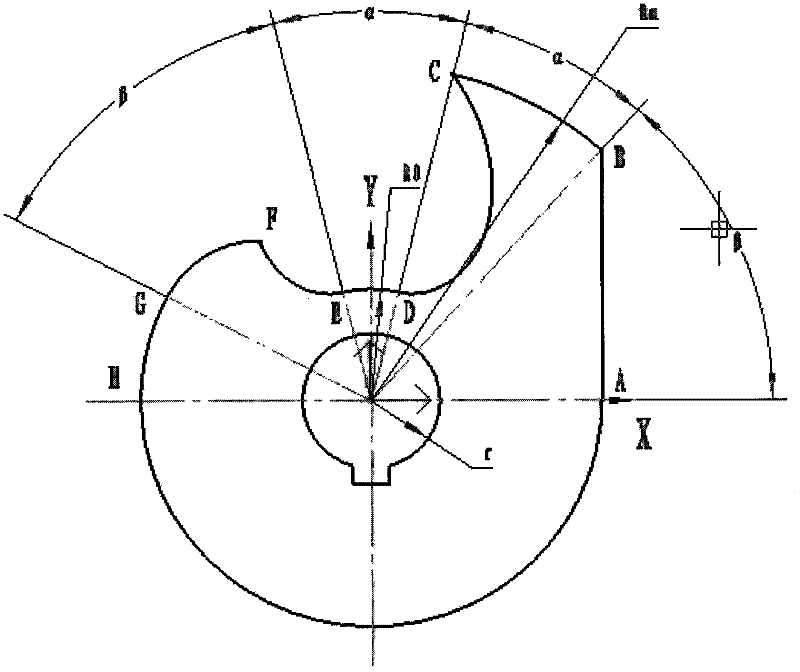

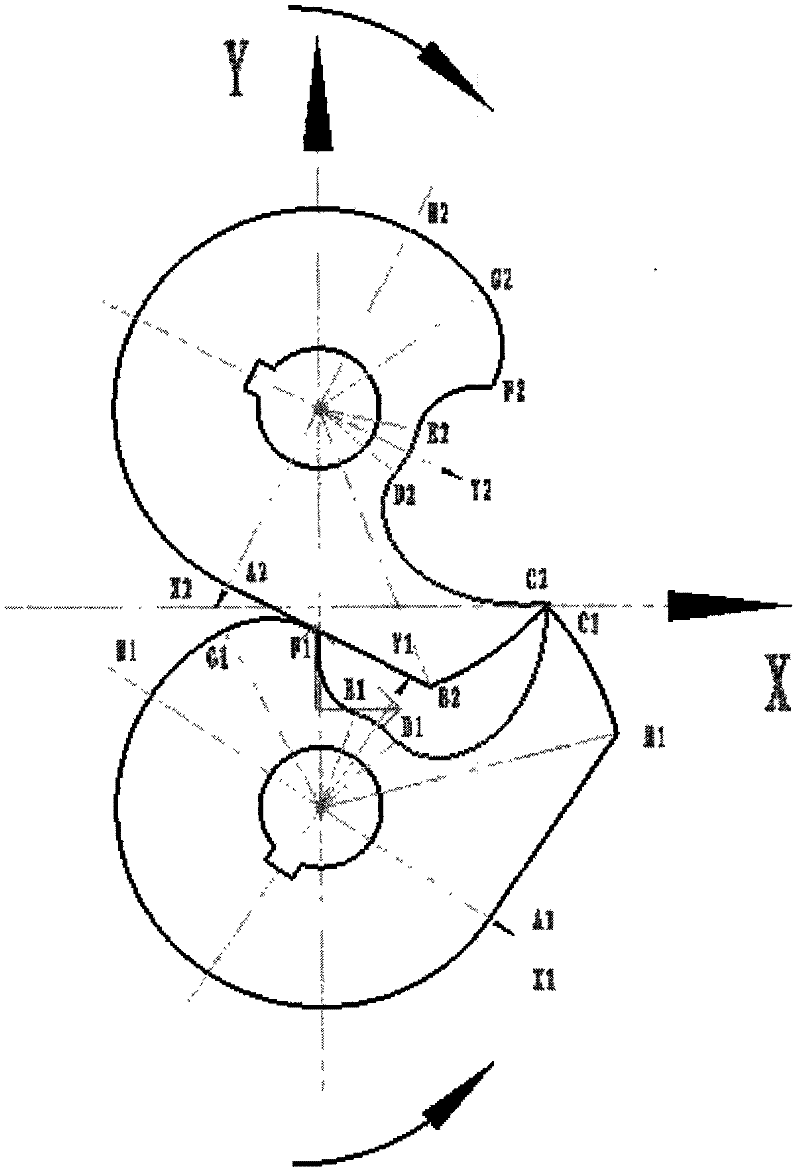

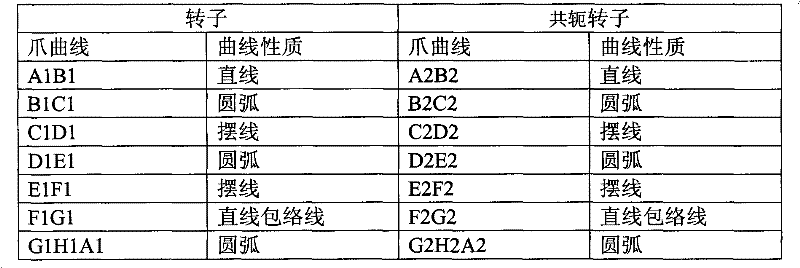

[0061] Such as Figure 1-2 As shown, a schematic diagram of the appearance of the rotor and the conjugate rotor formed by a seven-segment straight-claw rotor design method described in the embodiment of the present invention. The rotor formed by the seven-segment straight claw rotor design method described in the embodiment of the present invention includes the following curve segments: A1B1, B1C1, C1D1, D1E1, E1F1, E1G1, G1H1A1, connecting the above curves to form the outer shape curve of the rotor, The generation mechanism of each segment of the curve:

[0062] A1B1 is produced by F2G2 conjugation on the conjugated rotor;

[0063] B1C1 is a circular arc, which is produced by the conjugate of D2E2 on the conjugated rotor;

[0064] C1D1 is a cycloid, which is generated by the conjugate point C2 on the conjugated rotor;

[0065] D1E1 is a circular arc, which is produced by the conjugate of B2C2 on the conjugated rotor;

[0066] E1F1 is a section of cycloid, which is produce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com