Gas detection alarm

A gas detection and alarm technology, applied in alarms, instruments, fuel testing and other directions, can solve the problems of people's lives, property safety loss, single alarm form, easy to cause fire or explosion accidents, etc., to save early warning time, improve The effect of the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

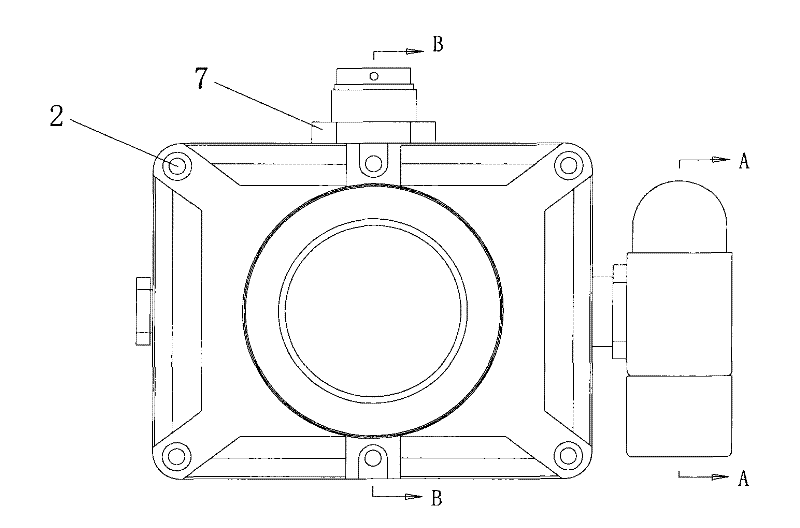

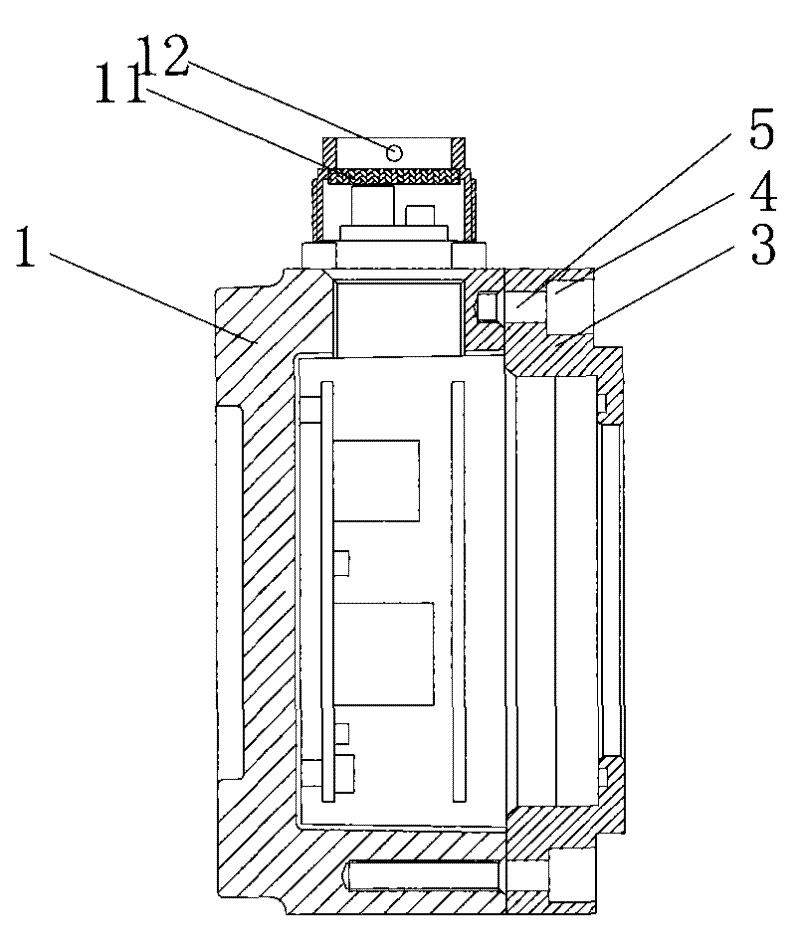

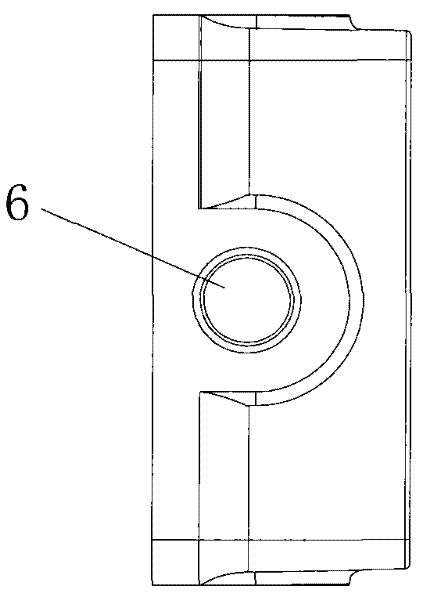

[0021] Such as Figure 1-8 As shown, a cuboid without a top surface is used as the lower shell 1 of the gas detection alarm, and the four side connecting parts of the lower shell 1 are rounded, and the thickness direction of the side is provided with a threaded hole 2 perpendicular to the bottom surface of the lower shell, The threaded hole 2 is set at the rounded corner of the side of the lower shell 1 and the middle part of a pair of opposite sides. Above the lower shell 1, an upper cover 3 matching the shape of the lower shell 1 is provided, and an upper cover 3 is provided on the edge part. There is a threaded through hole 4 corresponding to the position of the threaded hole 2 of the lower case 1. On the contact surface between the lower case 1 and the upper cover 3, epoxy resin is also applied. The bolt 5 passes through the threaded through hole 4 of the upper cover and is connected to the lower case. The threaded hole 2 of the shell 1, and the bolt 5 is screwed into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com