Method and equipment for forming and testing series-connected and monitored batteries

A technology of battery formation and series connection of battery packs, applied in battery circuit devices, measuring electricity, current collectors, etc., can solve the problems of single battery overcharging, time-consuming and unreliable, large footprint, etc., and achieves a small number of equipment used. , Time-saving and reliable operation, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

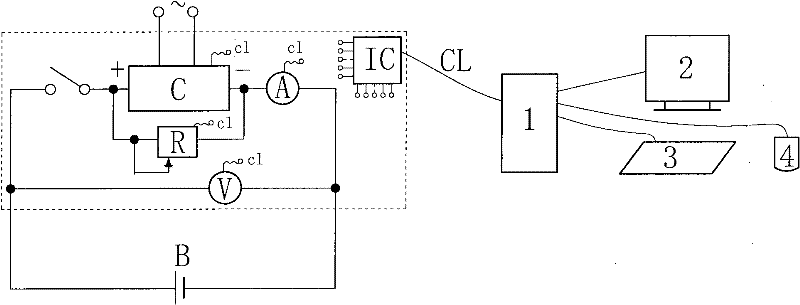

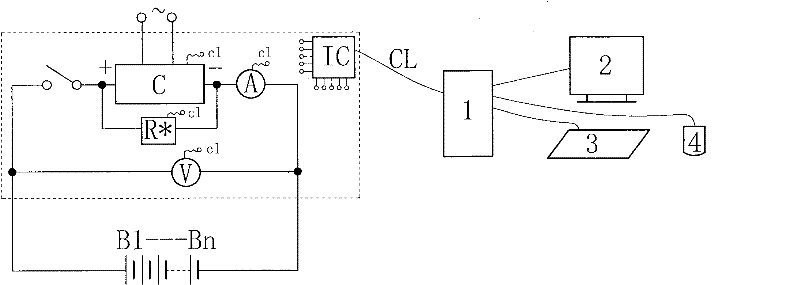

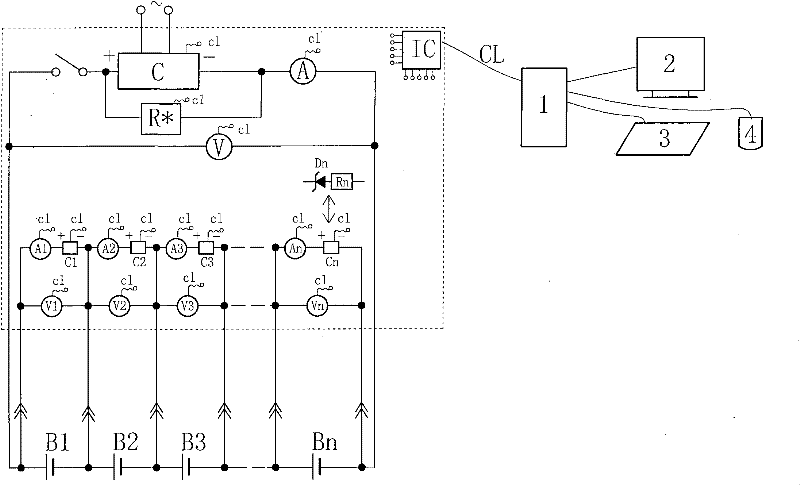

[0013] Such as image 3 Shown, the present invention is as a kind of battery forming (or testing) method, and it comprises to be formed (or testing) battery B1, B2, B3, ... Bn, the battery that is made up of main charger C, discharger R* etc. Formation (or testing) machine (in the dotted line box, including ammeter A, voltmeter V, internal signal line cl, signal converter IC, etc.), external signal line CL, control computer 1, display 2, keyboard 3. Mouse 4, etc., similar to figure 2 , the whole machine is connected to the control computer 1 through the internal signal line cl, the signal converter IC, and the external signal line CL, so that the control computer 1 can communicate with the whole machine, program the operation of the whole machine, obtain the current and voltage signals of the circuit, and draw The charge and discharge curve of a single battery is used to calculate its charge and discharge capacity. Its different feature is that it connects the batteries B1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com