Three level power converting device

A power converter and power conversion technology, which is applied to output power conversion devices, electrical components, and AC power input to DC power output, etc., can solve problems such as size increase, device price increase, and significant problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

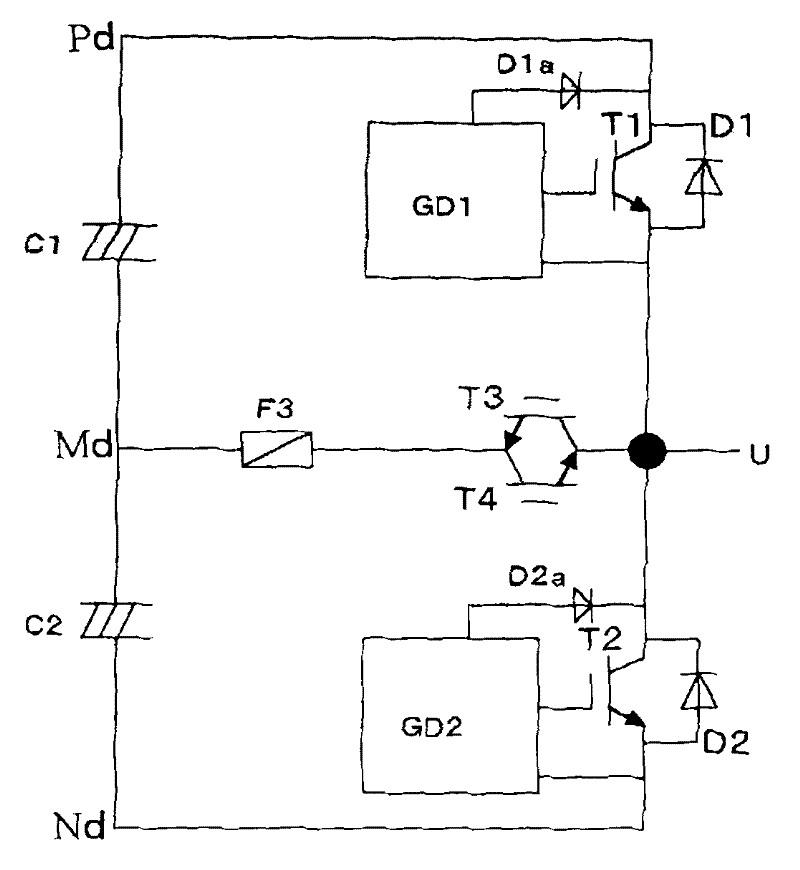

Embodiment 1

[0053] figure 1 A first embodiment of the invention is shown in . It is a circuit configuration of a voltage-type three-level power converter having a DC power supply, a first IGBT T1, a second IGBT T2, and a bidirectional switching element as one phase, and the DC power supply is configured with two capacitors C1 and C2 connected in series As a DC power supply, and has a positive pole, an intermediate electrode, and a negative pole; the collector of the first IGBT T1 is connected to the positive pole of the DC power supply, and the first IGBT T1 is connected in antiparallel to the diode D1; the emitter of the second IGBT T2 connected to the negative pole of the DC power supply, and the second IGBT T2 is connected in antiparallel with the diode; The connection point of the emitter of the first IGBT T1 and the collector of the second IGBT T2 is connected to the intermediate electrode of the DC power supply. Although a single-phase circuit is shown in the figure, a single-pha...

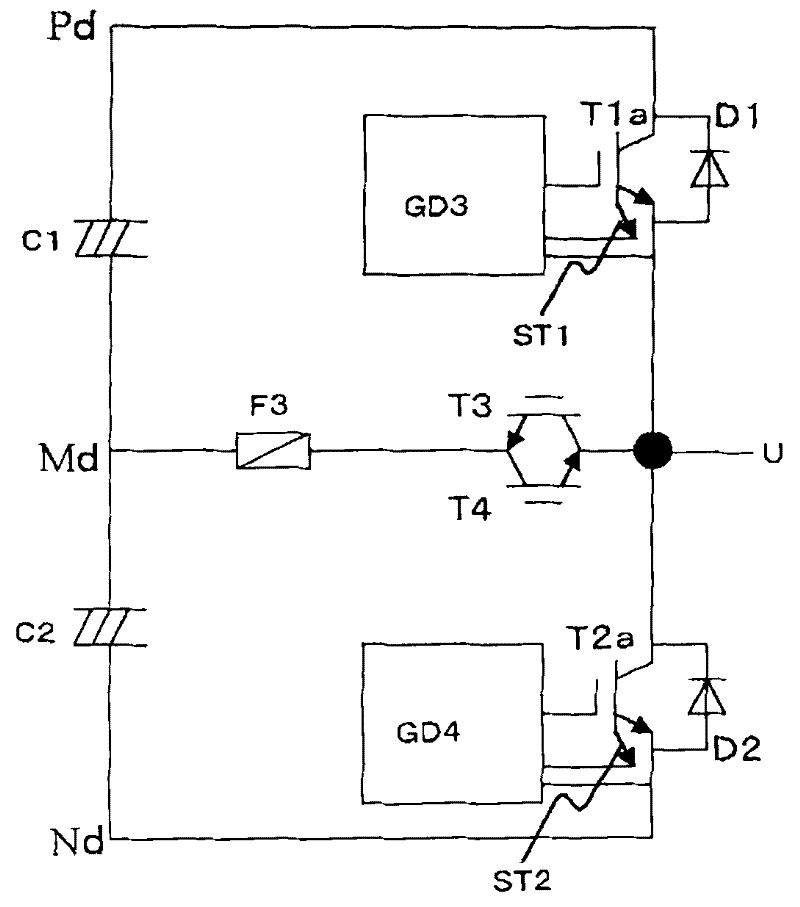

Embodiment 2

[0058] figure 2 A second embodiment of the present invention is shown. The difference from the first embodiment is that IGBTs with current sensing terminals for detecting current are used as IGBTs T1a and T2a, and the overcurrent shutoff unit detects overcurrent using the current sensing terminals and cuts off the gate signal. Since this overcurrent protection method is known from JP-A-4-79758 and the like, a detailed description is omitted. For this structure, the protection of each overcurrent path can also be realized in the same manner as in the first embodiment.

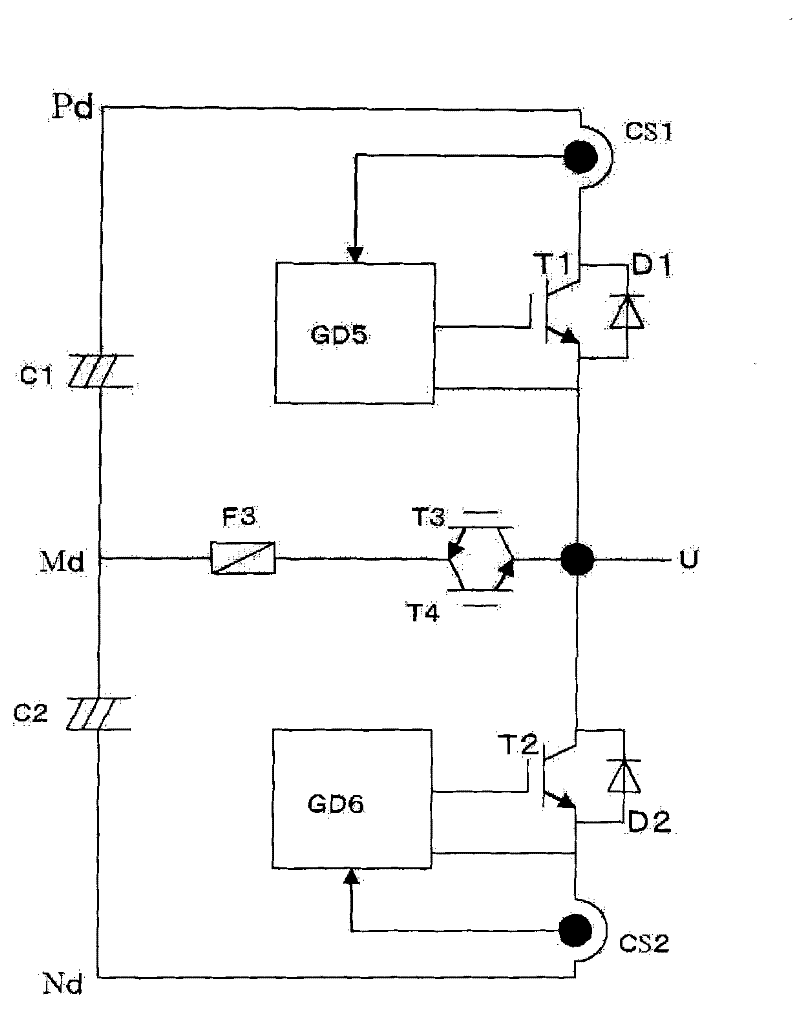

Embodiment 3

[0060] image 3 A third embodiment of the present invention is shown. The point of difference from the first and second embodiments is that current detectors CS1 and CS2 such as Hall CTs are used for overcurrent detection. When an overcurrent is detected, the ON signal of the gate drive circuit is cut off. For this structure, the protection of each overcurrent path can also be realized in the same manner as in the first and second embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com