Motor locked-rotor protecting method of electric car electric driving system

An electric drive system, electric vehicle technology, applied in electric vehicles, control drive, electric energy management, etc., can solve the problems of cost increase, inability to completely avoid burnout, etc., and achieve the effect of reducing current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

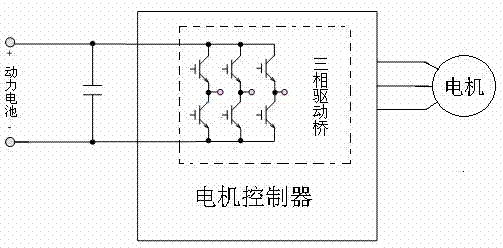

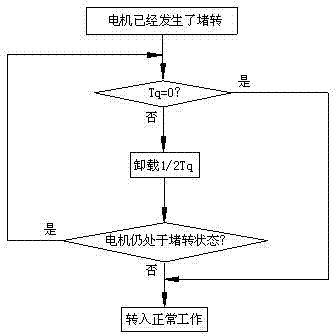

[0019] Such as figure 2 As shown, in the motor stall protection method of the electric drive system of the electric vehicle in this embodiment, the electric drive system of the electric vehicle is provided with a motor controller, and according to the torque demand of the accelerator pedal, the three-phase drive axle of the motor controller is used to drive the motor.

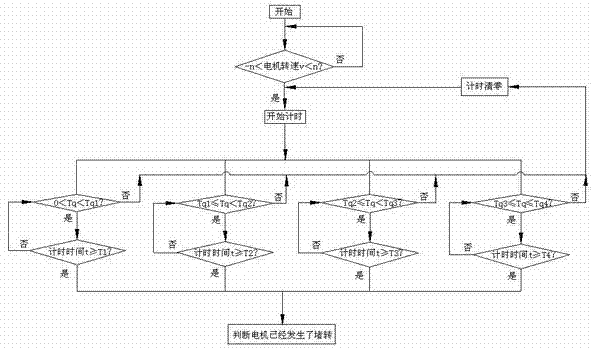

[0020] First, the motor controller detects the motor speed and torque in real time. When -nrpm<motor speed v<nrpm (n is a predetermined integer less than 100), the motor controller judges that the motor has stopped, and starts timing when the motor stops .

[0021] The motor controller divides the motor torque range from low to high into four intervals (0, Tq1), [Tq1, Tq2), [Tq2, Tq3), [Tq3, Tq4], among which the intervals (0, Tq1), [ The predetermined times T corresponding to Tq1, Tq2), [Tq2, Tq3), and [Tq3, Tq4] are sequentially T1, T2, T3, and T4, where T1>T2>T3>T4.

[0022] After the motor stops, the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com