Automatic charging and discharging device of die cutting machine

An automatic loading and unloading and die-cutting machine technology, which is applied in the direction of conveyor objects, transportation and packaging, etc., can solve problems such as high risk, and achieve the effect of guaranteeing work safety and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Specific implementation examples

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

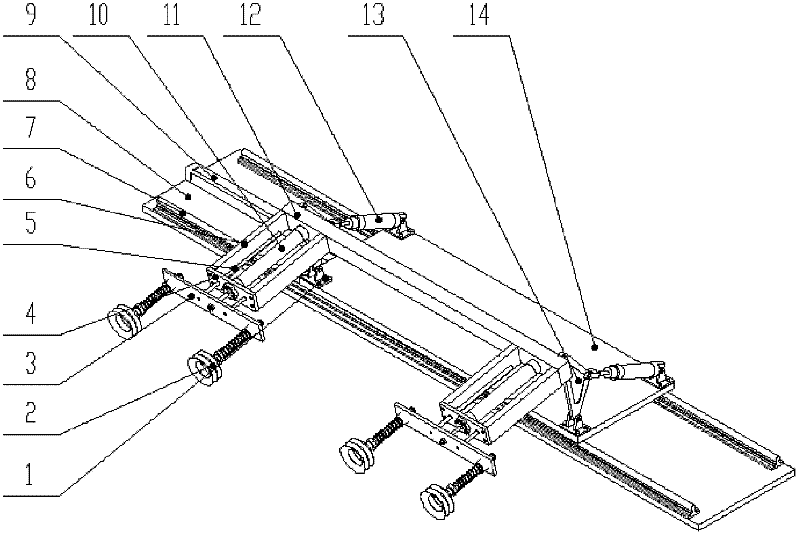

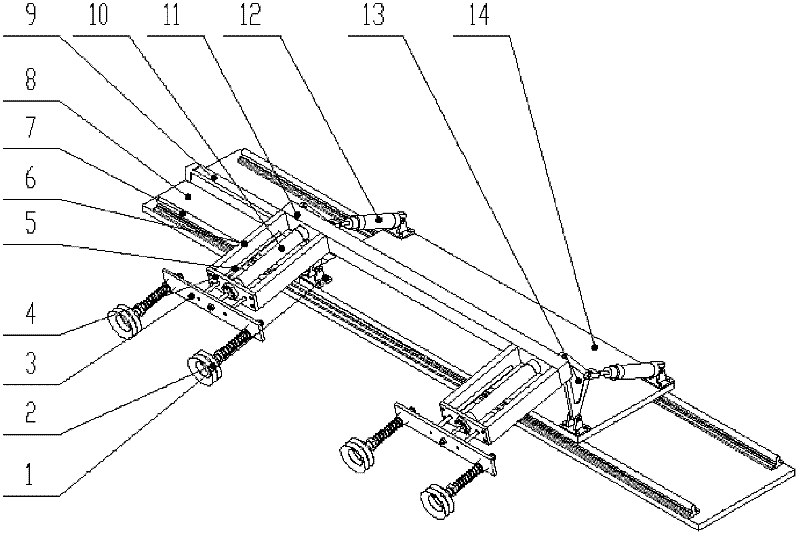

[0012] An automatic loading and unloading device for a die-cutting machine, including a twist support 1, a suction cup 2, a suction cup bottom plate 3, a cylinder top plate 4, a guide rod 5, a cylinder support block 6, a cylindrical guide rail 7, a guide rail bottom plate 8, an SU cylinder 9, small Cylinder 10, small cylinder bottom plate 11, rotary cylinder 12, connecting block 13, big moving plate 14, such as figure 1 As shown, wherein, the cylindrical guide rail 7 is symmetrically installed on both sides of the guide rail bottom plate 8; the large moving plate 14 is installed above the cylindrical guide rail 7; the SU cylinder 9 is installed on the upper side of the guide rail bottom plate 8 , the underside of the large movable plate 14; a pair of twisted supports 1 are symmetrically installed on one side of the large movab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com