Rotary damping buffering meshed type automobile motor

A technology of rotation damping and toothing, which is applied in the directions of stepless relays, engine components, engine starting, etc. It can solve the problems of gears not meshing and teeth breaking, etc., and achieve the effects of rapid starting, weight reduction and broad market prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

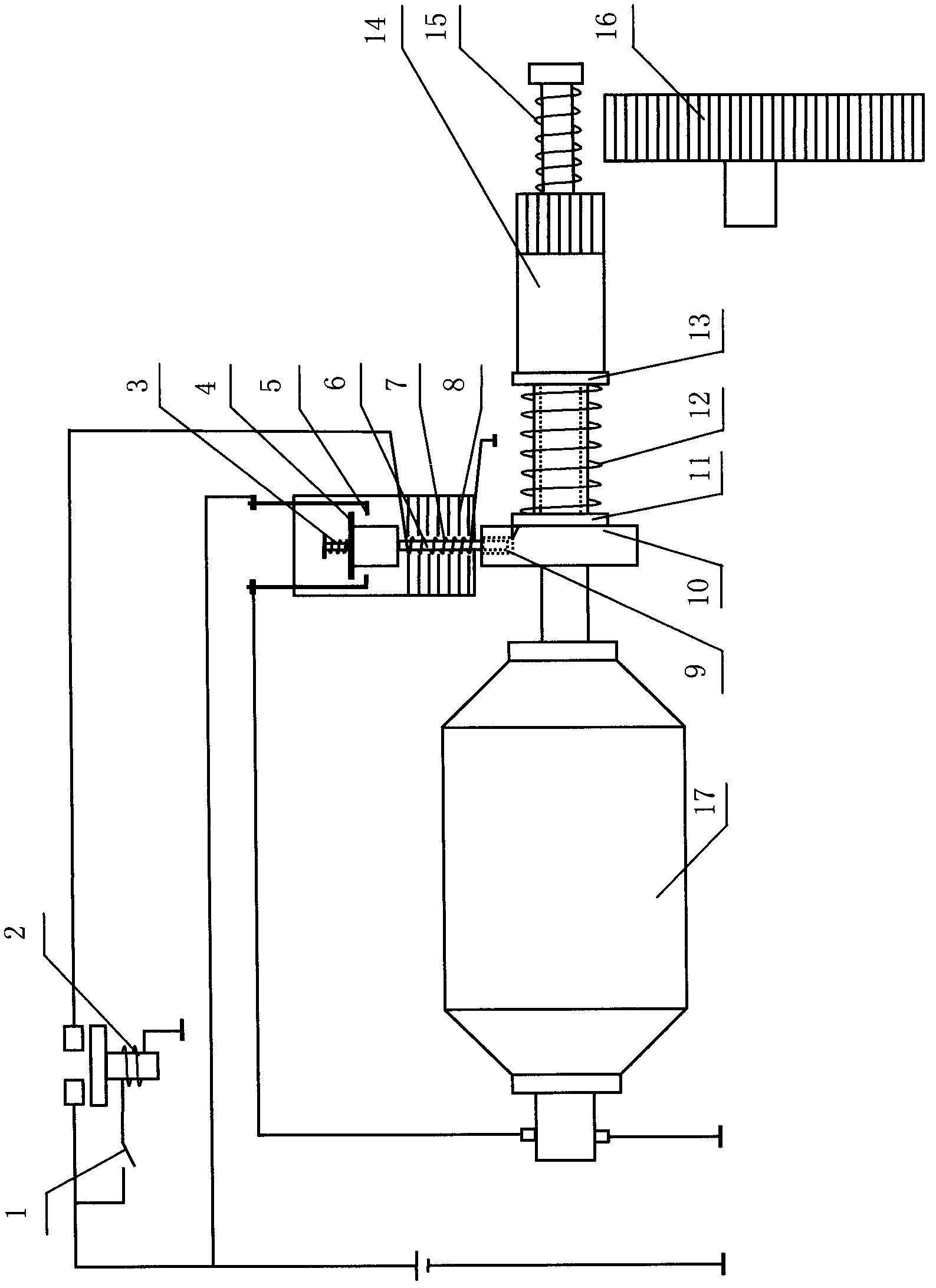

[0014] Such as figure 1 As shown, the present invention includes a transmission device, an electromagnetic switch, a motor rotor, and the like.

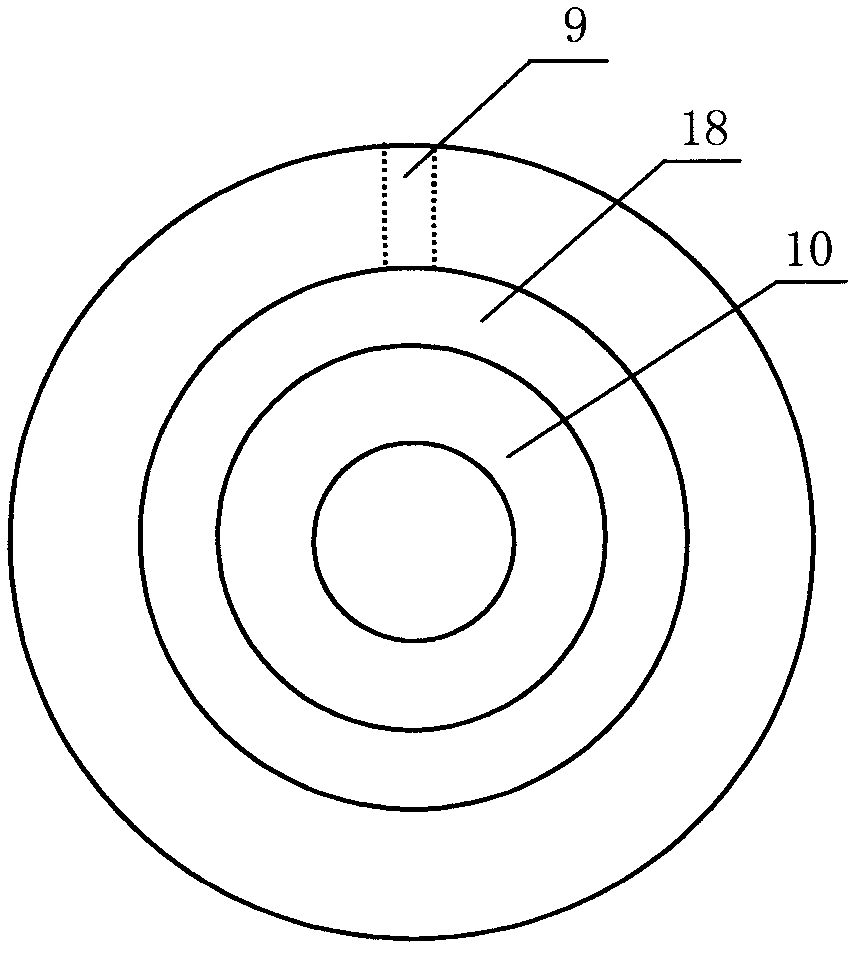

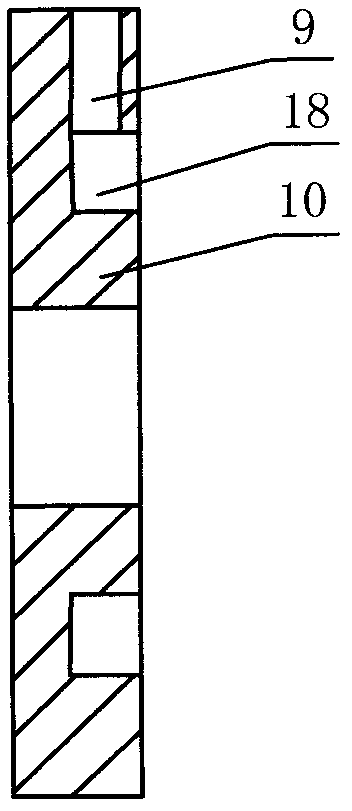

[0015] The transmission device includes a claw 11, a one-way spring 12, a round iron plate 13, a one-way clutch 14, a return thin spring 15, and the like. The one-way clutch 14 is an internal thread spring type, and plays the role of transmission engagement and disconnection when starting. Described claw 11 is provided with a protruding position on the disc, preferably triangular.

[0016] The left end of the one-way clutch 14 is fixed with a round iron plate 13, and a return thin spring 15 is arranged between the right end and the stop screw. The spring 12 of the one-way device adopts a counterclockwise direction spring, which is a kind of anti-spring, which becomes tighter and tighter when it encounters the resistance in the opposite direction, and plays the role of buffering and damping and fixing the iron plate as one. One end...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap