Rapid inflation gun

An inflatable gun, fast technology, applied in the direction of container filling method, gas/liquid distribution and storage, function valve type, etc., can solve the problems of difficult operation, low efficiency, increased operation time, etc., to achieve simple and convenient use, fast inflation speed , the effect of high inflation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

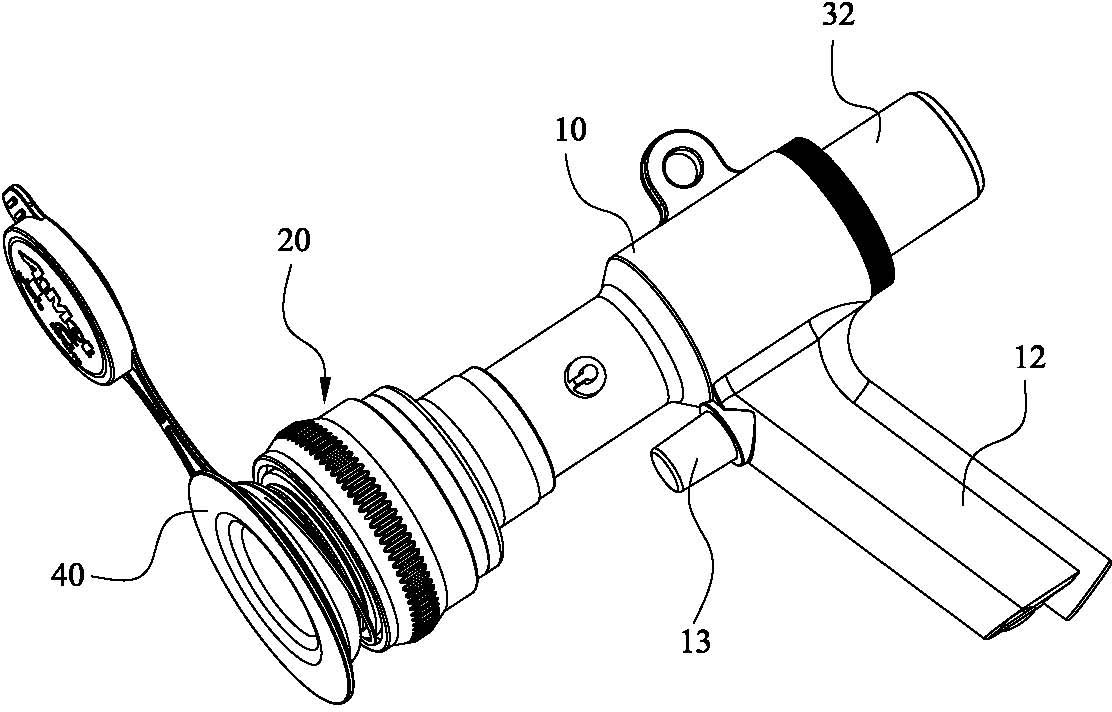

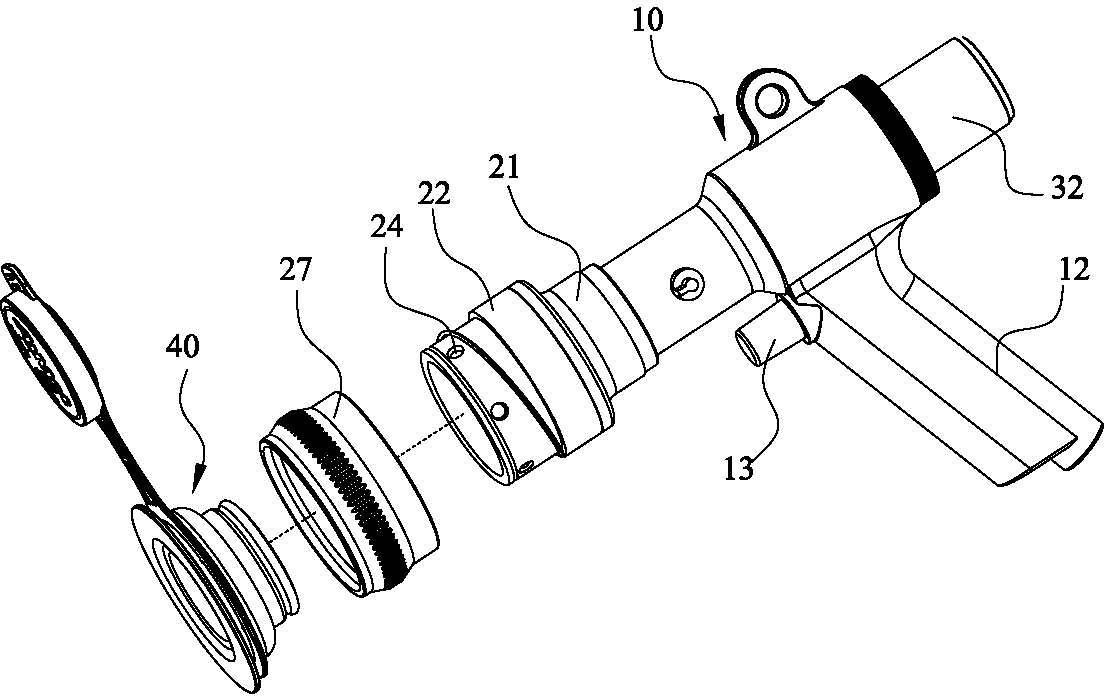

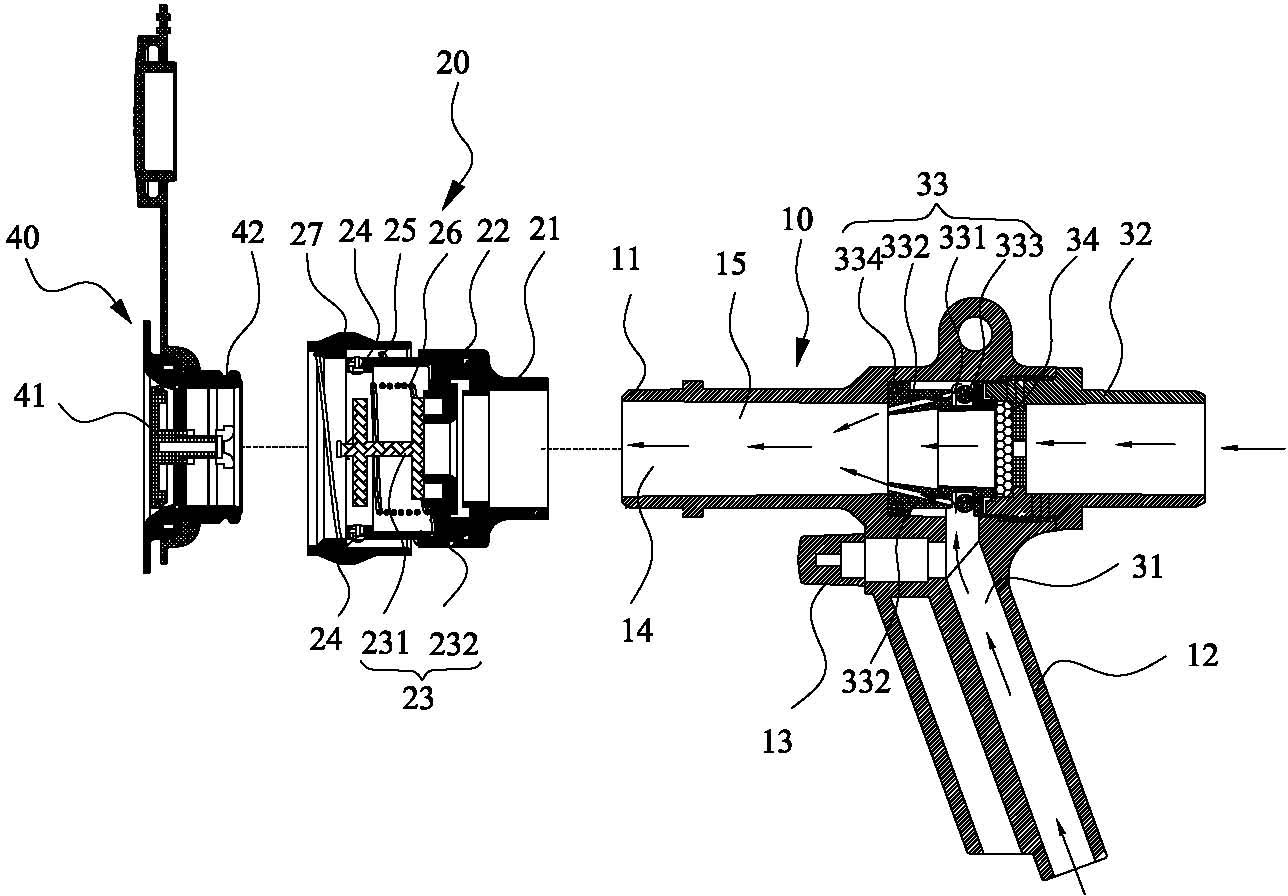

[0040] Please refer to Figure 1 to Figure 3 As shown, it shows the specific structure of the preferred embodiment of the present invention, which includes the gun body 10 of the air gun, the connector assembly 20 assembled on the muzzle 11 of the gun body 10 and the other end of the gun body 10 The first air intake pipe 31, the second air intake pipe 32 and the air source connector 33.

[0041] Specifically, the front end of the gun body 10 has a muzzle 11 for installing the connector assembly 20, the middle part has a hollow air channel 15 for the passage of the inflation air source, and the rear lower end has a handle 12 that is convenient to hold. , the outer side of the upper end of the handle 12 is provided with a switch button 13 for controlling the on / off of the inflation. The side of the air duct 15 near the muzzle 11 has an air outlet 14 .

[0042] The first air intake pipe 31 is arranged in the handle 12 of the gun body 10, and extends from the lower end of the ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com