Air conditioner for machine room

A technology for air conditioners and computer rooms, applied in air conditioning systems, applications, refrigerators, etc., can solve problems such as equipment condensation, difficulty in judging whether the air quality meets the requirements, corrosion, etc., and achieve the effect of avoiding condensation and air quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

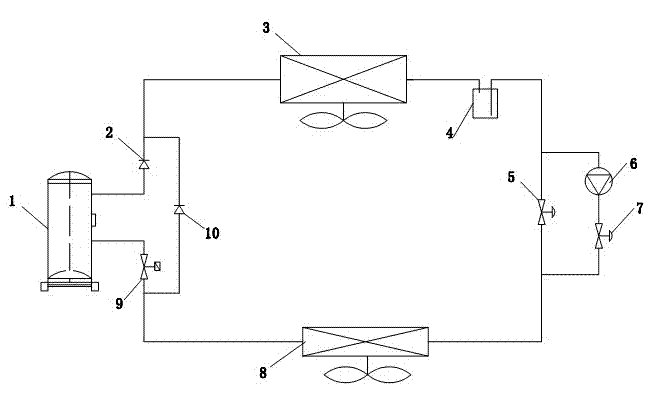

[0013] Such as figure 1 As shown, the air conditioner used in the machine room of the present invention includes a compressor 1, a first one-way control valve 2, a condenser 3, a liquid reservoir 4, a first throttling device 5, an evaporator 8, and an on-off control valve 9. Liquid pump 6, second throttling device 7 and second one-way control valve 10, wherein the outlet of compressor 1 is connected to the inlet of condenser 3 through the first one-way control valve 2, and the outlet of condenser 3 is connected to The inlet of the liquid reservoir 4, the outlet of the liquid reservoir 4 is connected to the inlet of the evaporator 8 through the first throttling device 5, the outlet of the evaporator 8 is connected to the inlet of the on-off control valve 9, and the outlet of the on-off control valve 9 Connected to the inlet of the compressor 1, the liquid pump 6 is connected in series with the second throttling device 7 and connected to both ends of the first throttling device ...

Embodiment 2

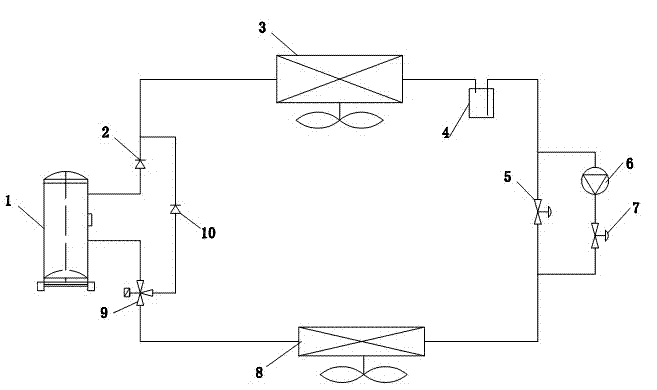

[0017] The difference between this embodiment and embodiment 1 is: as figure 2 As shown, the on-off control valve 9 is a three-way on-off control valve, the inlet of the three-way on-off control valve is connected to the outlet of the evaporator 8, one outlet is connected to the inlet of the compressor 1, and the other outlet is connected to the second one-way control valve 10. Entrance. In the energy-saving operation mode of this embodiment, the refrigerant is powered by the liquid pump 6, throttled by the second throttling device 7, evaporates in the evaporator 8, and then passes through the three-way on-off control valve 9 and the second one-way control valve in sequence. 10 to the condenser 3 to condense, and then return to the liquid pump 6 after passing through the liquid reservoir 4, so that the energy-saving mode refrigeration can be realized in such a cycle. Other structures and working principles are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com