Machine inching control system and method and numerical control machine

A control method and machine tool technology, applied in the field of control, can solve problems such as inability to complete simultaneous JOG actions of multiple axes, complex parameter settings, and inability to realize continuous adjustment of JOG speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment firstly provides a jogging control system for a machine tool, and the specific scheme is as follows.

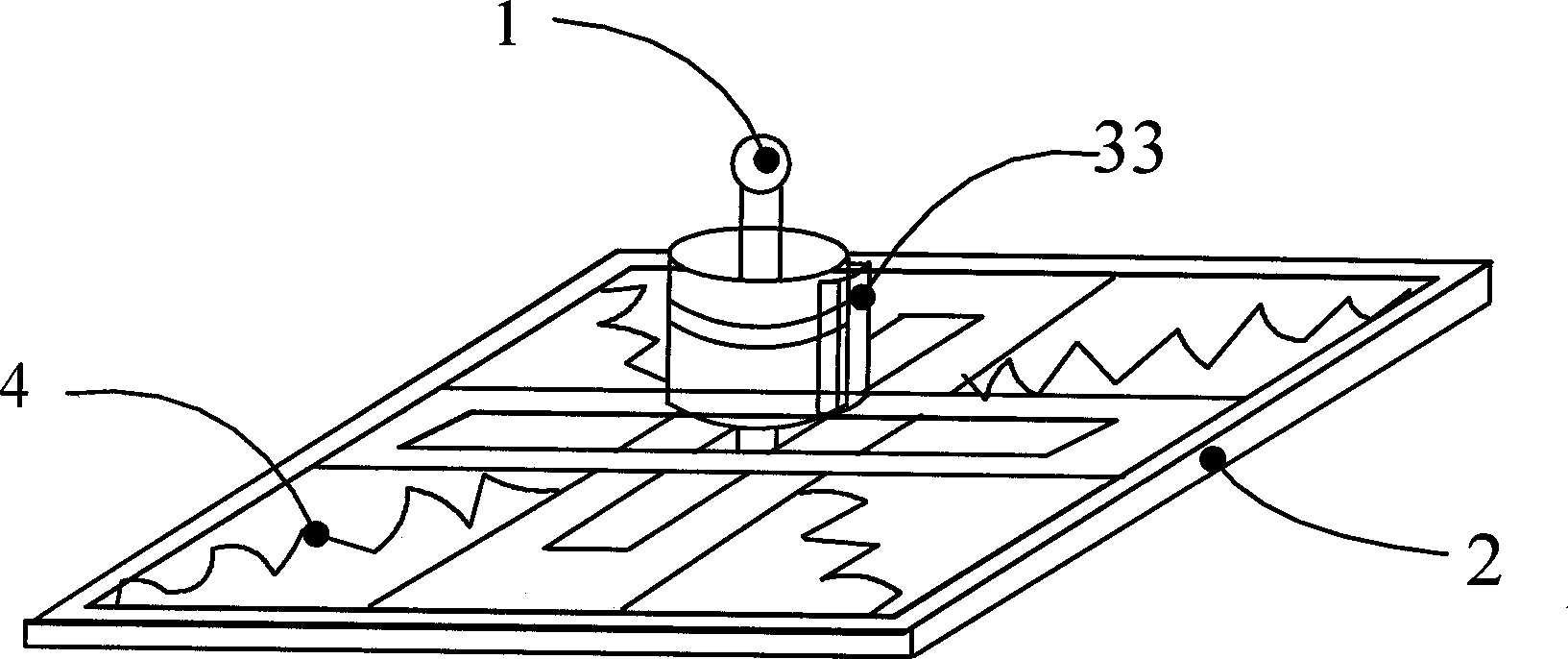

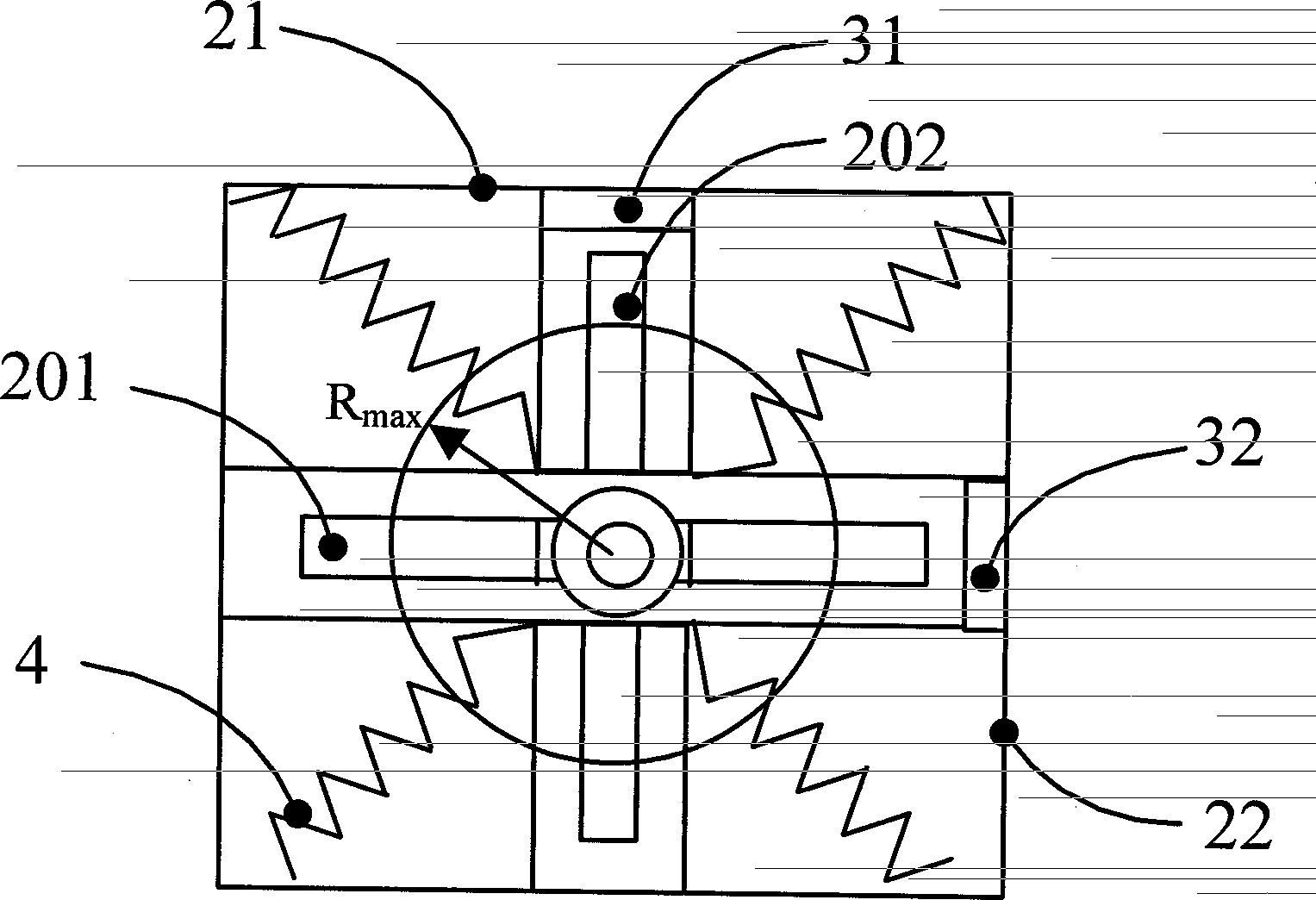

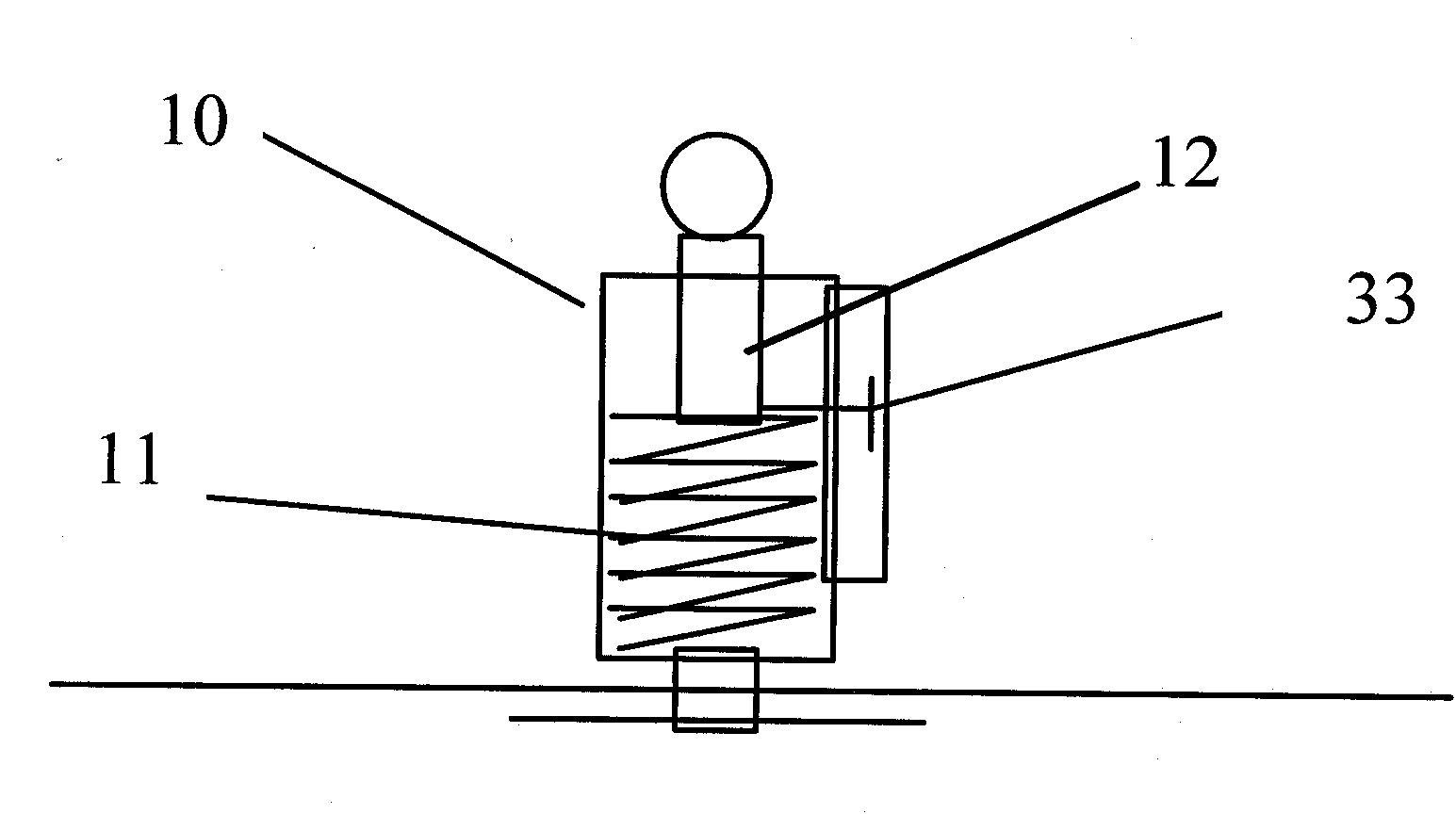

[0030] refer to figure 1 , figure 2 with image 3 As shown, the machine tool inching control system provided by this embodiment includes an operating head 1, an auxiliary mechanical structure, a position detection device and a control component; the operating head 1 moves and positions in three-dimensional space under the support of the auxiliary mechanical structure; The auxiliary mechanical structure is connected with the operation head to provide support for the movement of the operation head in three-dimensional space; the position detection device detects the position information of the operation head in three-dimensional space in real time and feeds back to the control part; the control The component receives the position information of the operation head fed back by the position detection device, and controls the movement of the machine tool o...

Embodiment 2

[0063] This embodiment provides a method for machine tool jog control. This method can be implemented by using the machine tool jog control system described in Embodiment 1. Of course, a device with a similar structure can also be used. The machine tool point of this embodiment will be described in detail below. motion control method.

[0064] The machine tool inching control method of the present embodiment includes the following steps:

[0065] S10: the position detection device detects in real time the position information of the operation head supported by the auxiliary mechanical structure in the three-dimensional space and feeds back to the control component;

[0066] S20: The control component receives the position information of the operation head fed back by the position detection device;

[0067] S30: Select the way to control the movement of the drive shaft as single-axis drive, double-axis linkage or three-axis linkage;

[0068] S40: The control component convert...

Embodiment 3

[0095] This embodiment provides a CNC machine tool, which includes a machine tool with at least three drive shafts, the machine tool is provided with a machine tool jog control system, and the structure and functional principles of the machine tool jog control system are the same as those described in Embodiment 1 Or similar, to manually control the JOG movement of the machine tool spindle. The JOG movement is realized by the corresponding drive shaft, which can be carried out in single-axis drive, double-axis linkage and three-axis linkage.

[0096] In addition, the above machine tool jog control system can be wirelessly connected to the machine tool, so as to realize the remote control of the CNC machine tool. In addition, in the jog control system of the machine tool, a wireless connection can also be used between the manipulation part 1 and the control part 2 .

[0097] The CNC machine tool of this embodiment adopts the above-mentioned structure, not only can realize the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com