Quick-tightening device for chain saw and chain unit for same

A technology of tensioning device and chain unit, applied in chainsaws, sawing equipment, manufacturing tools, etc., can solve problems such as difficulty in adjusting the saw chain and re-tensioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

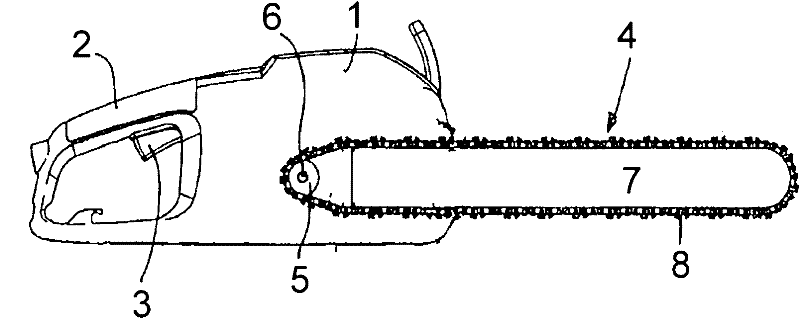

[0053] figure 1 By way of example, a main body 1 of a chain saw is shown schematically, which has a drive unit (not shown) for driving a saw chain 8 . On the body 1 there is a lever 2 with a switch 3 for switching the drive unit on and off. The main body 1 is shown without a housing cover covering the chain drive in operation, so that the chain unit 4 including the blade 7 , the saw chain 8 and the drive pinion 5 can be seen. The drive pinion 5 is connected to the drive unit via a drive shaft 6 for driving the saw chain 12 . The wedges and spacers mounted on the blade 7 are not shown in this illustration.

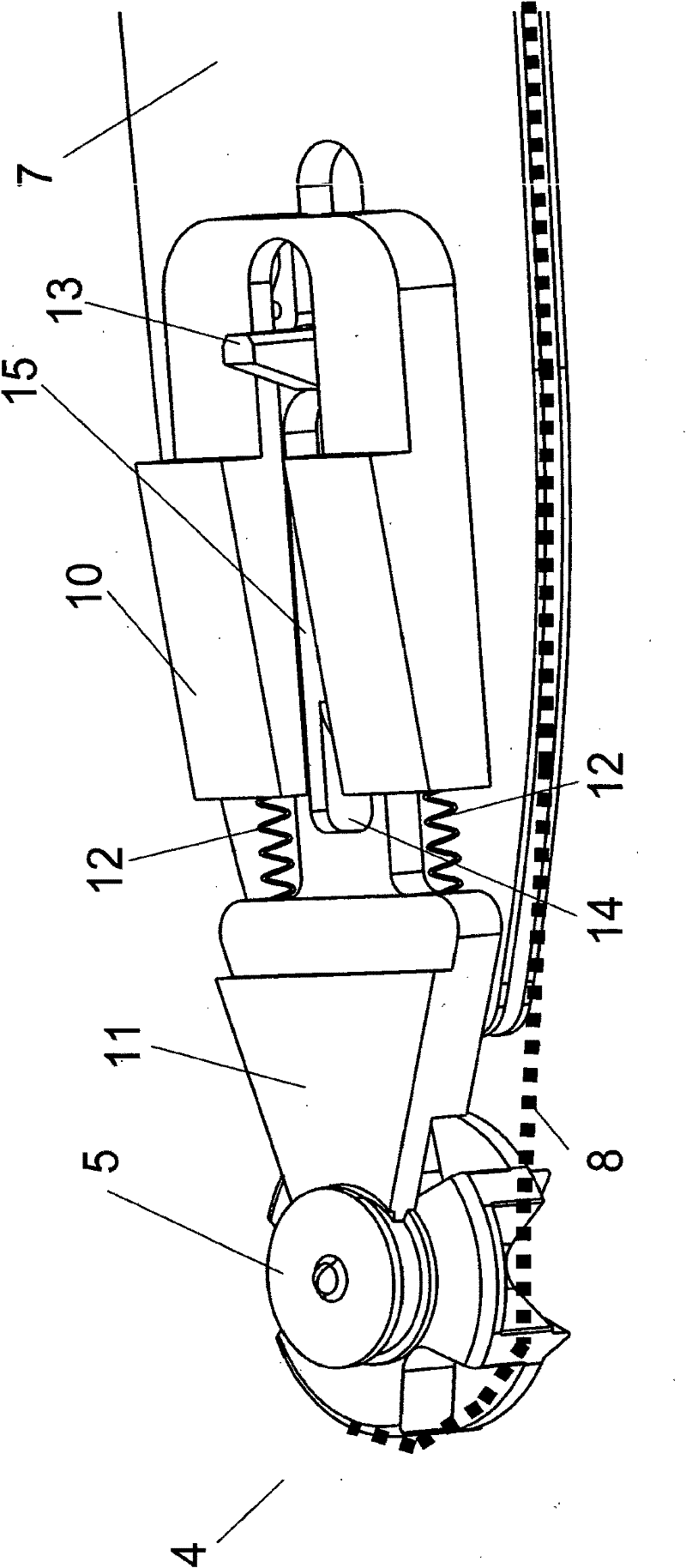

[0054] figure 2 A possible advantageous embodiment of the chain unit 4 is shown in . In order to better see the individual details of the chain unit 4 , only the saw chain 8 is sketched roughly here. The saw chain 8 runs around the drive pinion 5 and the blade 7 as usual. For this reason, and for the sake of clarity, the depiction of the saw chain 8 has been complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com