Device for rolling coiled belt out

A flattening and rolling technology, which is applied in the field of LED optoelectronic products, can solve problems such as uneven winding, bending of winding, and affecting the accuracy and smoothness of feeding, achieving multiple varieties, improving work efficiency, and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

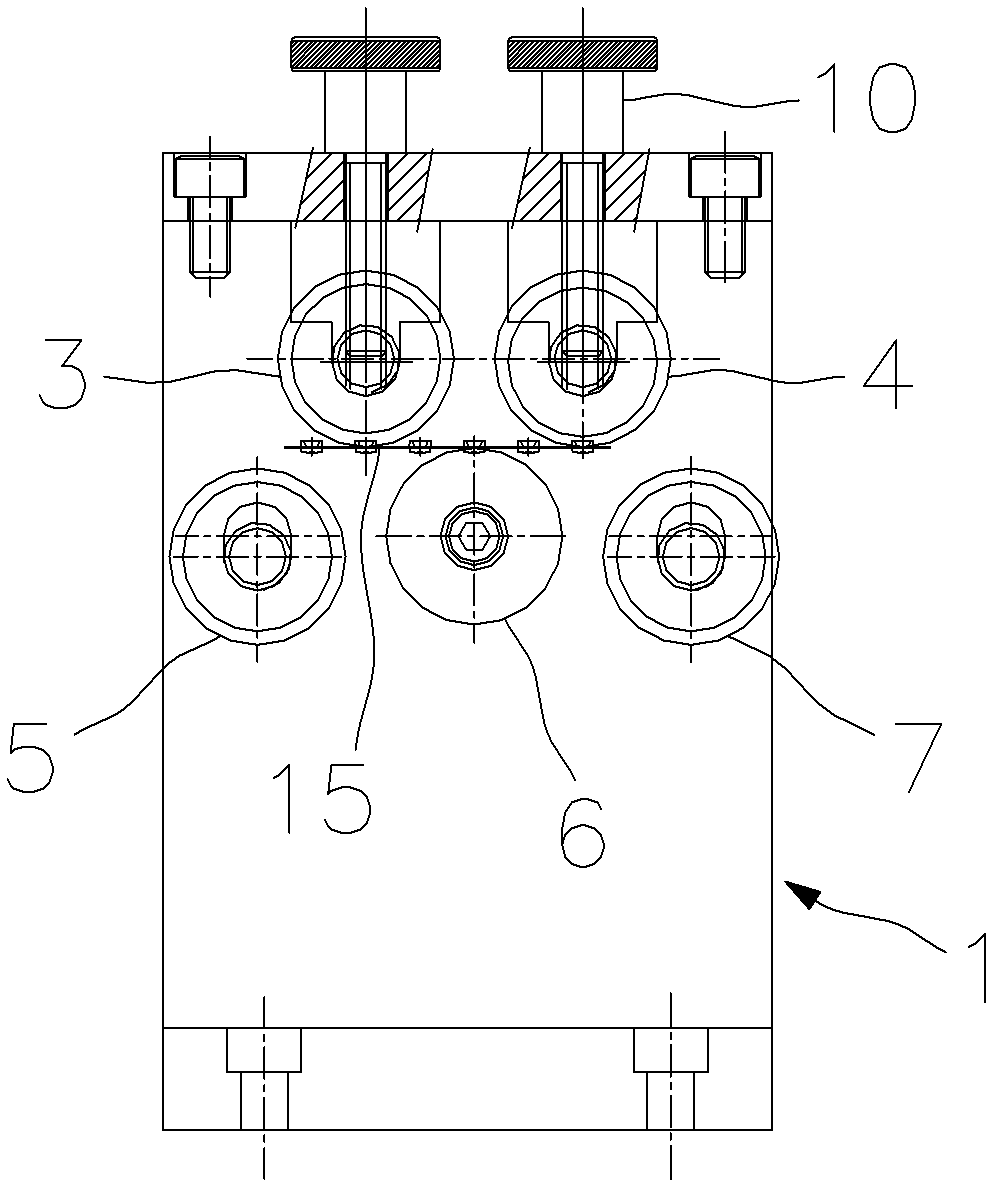

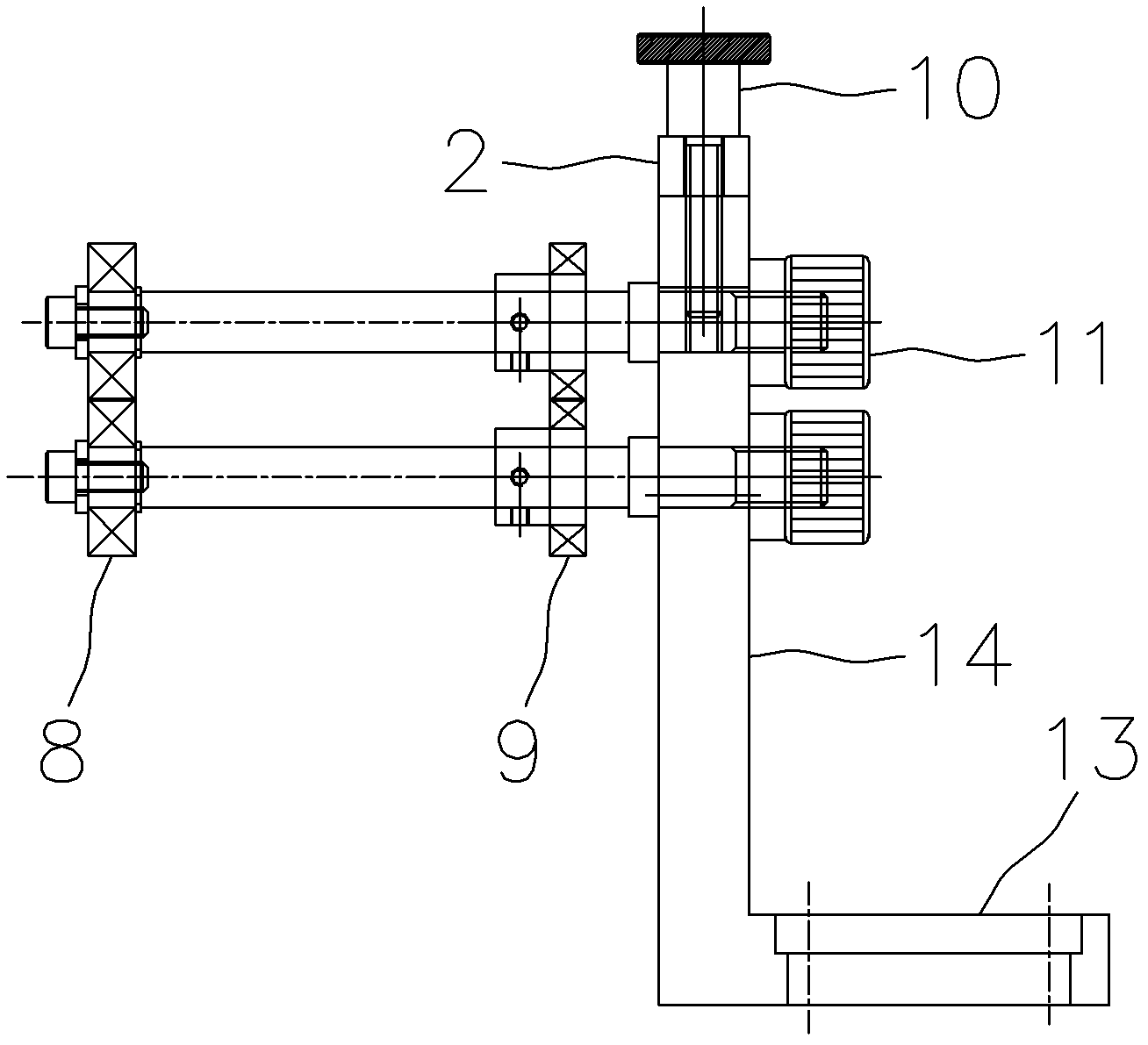

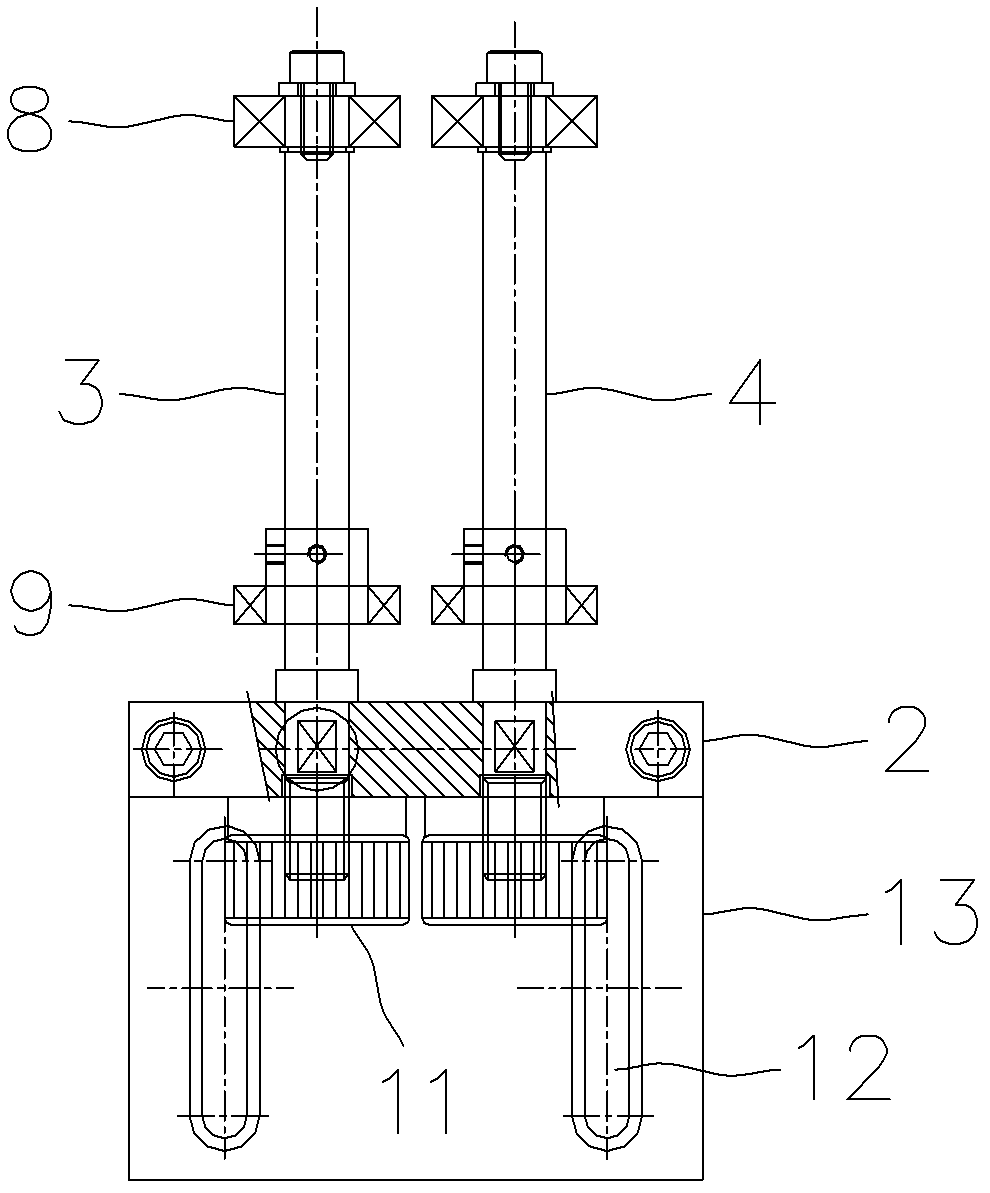

[0029] like Figure 1~4 As shown, a tape flattening device, the device includes a support 1, the support 1 is provided with a mounting hole 12 to fix its position, and the support 1 is also provided with a flattening part for flattening the tape 15 , there is a flattening gap for the tape to pass between the flattened parts.

[0030] Preferably, the flattening components are rod-shaped or shaft-shaped components, and the flattening components are at least divided into two rows arranged in parallel, and the flattening gap is formed between the two rows of flattening components.

[0031] like figure 1 , 2 As shown, the support 1 is composed of a horizontal horizontal plate 13 and a vertical vertical plate 14, and the flattened part is fixed on the vertical plate 14; the mounting hole 12 on the support 1 is Elongated waist-shaped holes.

[0032] Further, such as figure 1 , 2 As shown, the flattening parts are divided into upper and lower rows arranged in parallel, the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com