Stirring shaft fixing device for horizontal cake making machine

A technology of fixing device and stirring shaft, applied in the direction of presses, manufacturing tools, etc., can solve the problems of reduced bearing service life, machine cavity wear, and increased cleaning frequency, etc., to extend service life, improve production efficiency, and reduce cleaning. The effect of frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

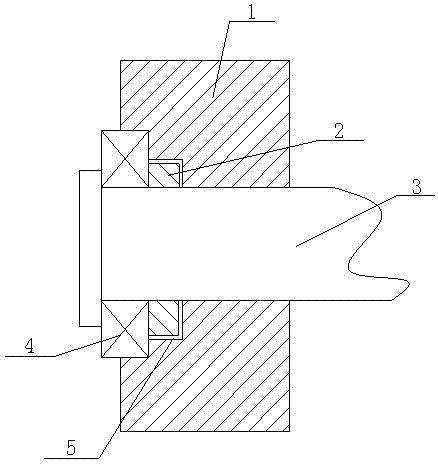

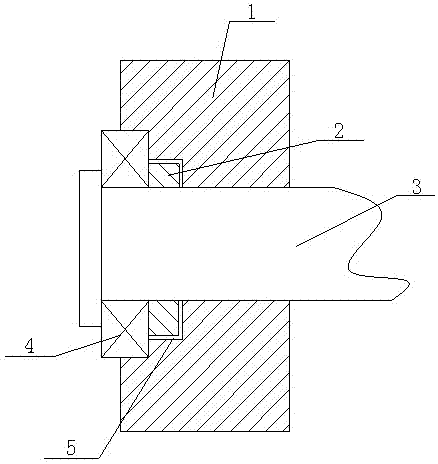

[0013] figure 1 The agitating shaft fixing device of a horizontal cake making machine is shown, comprising a cavity 1, a stirring shaft 3 arranged in the cavity 1, the agitating shaft 3 is fixed in the cavity 1 through a bearing 4, and the cavity 1 is set There is a groove 5, and a washer 2 is arranged in the groove 5, and the connection mode of this structural component forms a fixing device, which plays a bearing fixing effect.

[0014] More specifically: the depth of the groove 5 is 5mm, which is used to place the filled gasket 2, and increase the friction between the outer ring of the stirring shaft 3 bearing and the inside of the cavity 1, and the Teflon gasket can be directly replaced after this point is worn. Chamber 1 does not need to be replaced.

[0015] The washer 2 is a Teflon ring, which prevents fine powder from entering the inside of the bearing 4 during the operation of the cake making machine.

[0016] The use of this fixing device prevents dust from enterin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com