Magnetic suspension

A magnetic and suspension technology, applied in suspension, elastic suspension, transportation and packaging, etc., can solve the problems of large consumables, large structure, easy fatigue damage, etc., and achieve the solution of large steel consumption, convenient maintenance and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

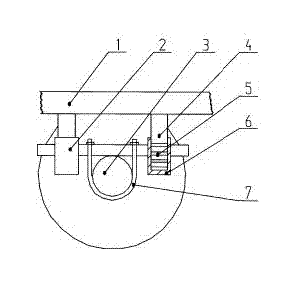

[0009] A magnetic suspension, comprising a vehicle beam 1 and an axle 3, a suspension 2 is arranged on the axle 3, a guide sleeve 6 is fixedly arranged on the suspension 2, and two permanent magnets with opposite polarities are arranged in the guide sleeve 6 Magnets 5, two permanent magnets 5 with opposite polarities are arranged at the bottom of the guide sleeve 6, the space between the magnets repelling each other is a buffer stroke, and one of the permanent magnets is movably arranged above the other, and a The guide post 4, the lower end of the guide post 4 is movably arranged on the permanent magnet 5 in the guide sleeve 6.

[0010] The suspension 2 is fixedly connected with the axle 3 through a U-bolt 7 .

[0011] The suspension 2 is installed between the vehicle beam 1 and the axle 3, and the suspension 2 is fixed on the axle 3 through the U-bolt 7. The guide post 4 is in the guide sleeve 6, and there are 3 to 5 permanent poles installed with opposite polarities during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com