Supporting seat for balance shaft of heavy vehicle axle

A technology for trucks and balance shafts, which is applied to vehicle components, interconnection systems, suspensions, etc., can solve the problems of high material requirements and increased production costs, and achieve the effect of optimizing product weight and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

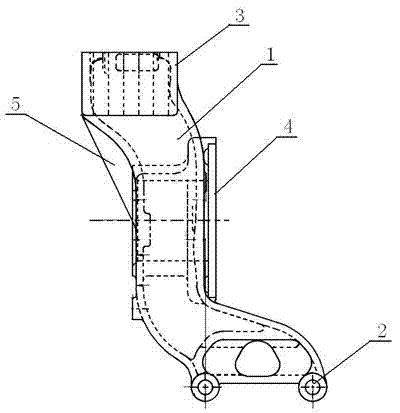

[0007] As shown in the drawings, it includes a support column 1 , a pin hole 2 , a beam connector 3 , a balance shaft hole 4 , and a reinforcing rib 5 .

[0008] The bottom of the support column 1 is provided with a pin shaft hole 2, and the top of the support column 1 is provided with a crossbeam connector 3 integrally cast and formed as one. Triangular reinforcing ribs 5 are arranged between the pieces 3 . The overall maximum stress of the balance shaft bearing seat is reduced from the traditional 710MPa to 495MPa, and the maximum stress reduction rate reaches more than 30%, which can properly optimize the product weight and reduce the production cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com