Double splicing curvilinear type gear hob

A gear hob and curved technology, which is applied in gear tooth manufacturing tools, gear tooth manufacturing devices, belts/chains/gears, etc., can solve the problem of weak tooth root strength of gears

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

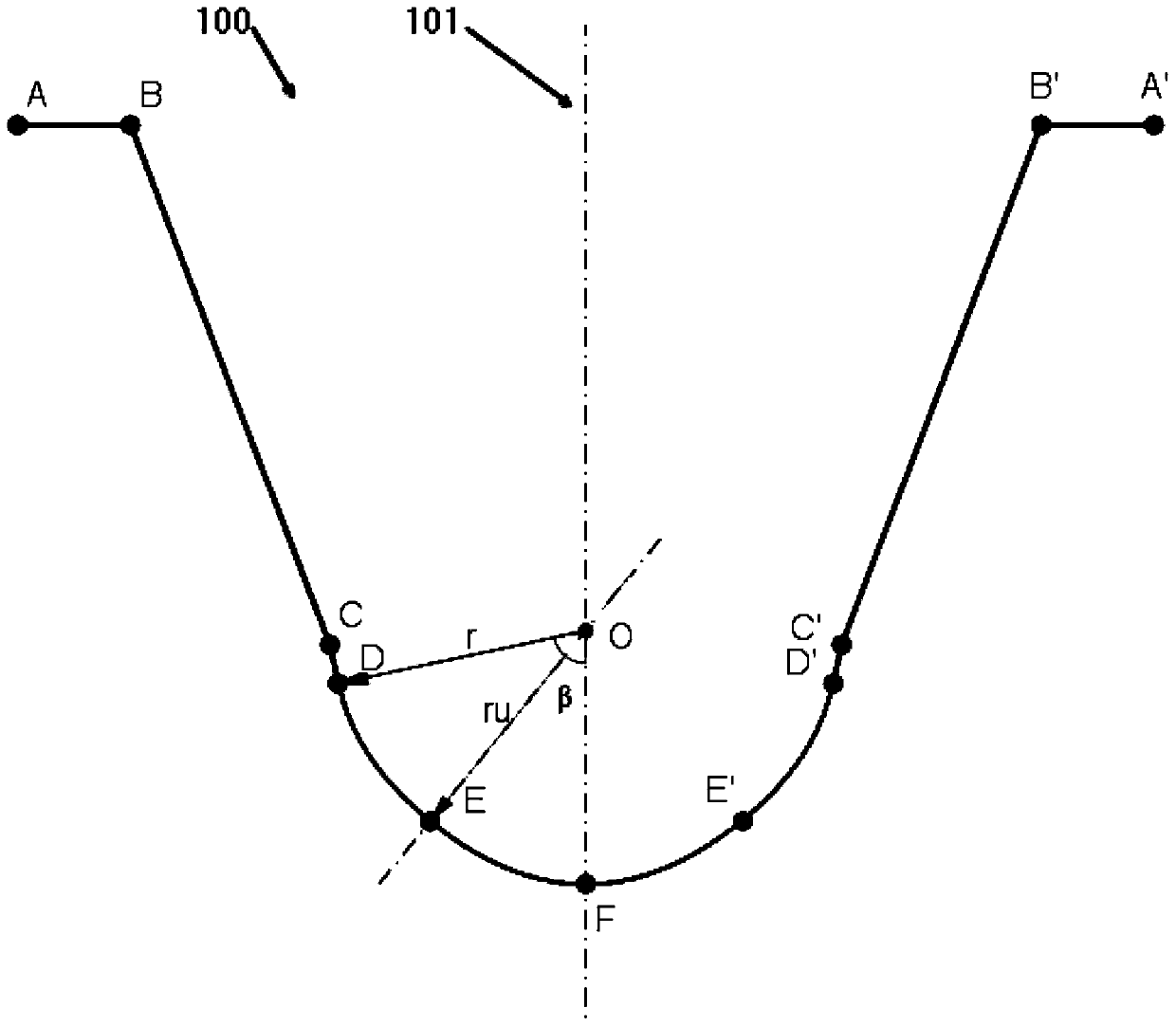

[0020] Such as figure 1 As shown, a double curved gear hob includes a plurality of hob teeth 100 . The tooth profile of the hob tooth 100 includes: the first dedendum straight line AB, the first main cutting straight line BC, the first auxiliary cutting straight line CD, the first addendum curve DF, and the second addendum curve D'F connected in sequence. , the second auxiliary cutting straight line C'D', the second main cutting straight line B'C' and the second dedendum straight line A'B'.

[0021] The first addendum curve DF is connected to the first secondary cutting straight line CD and is tangent at the connection point. Specifically, the first addendum curve DF and the first secondary cutting straight line CD are connected at point D, or the connection point is point D. The first addendum curve DF is tangent to the first secondary cu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com