Large-span double-arch axis combined arch bridge and construction method thereof

A construction method and arch axis technology, which is applied in bridge construction, architecture, bridges, etc., can solve the problems of large vertical displacement in the arch waist range, high cost of main arch section materials, and difficulty in meeting functional requirements, etc., to achieve arch waist vertical The effects of small axial displacement, shortened construction period, and reduced construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

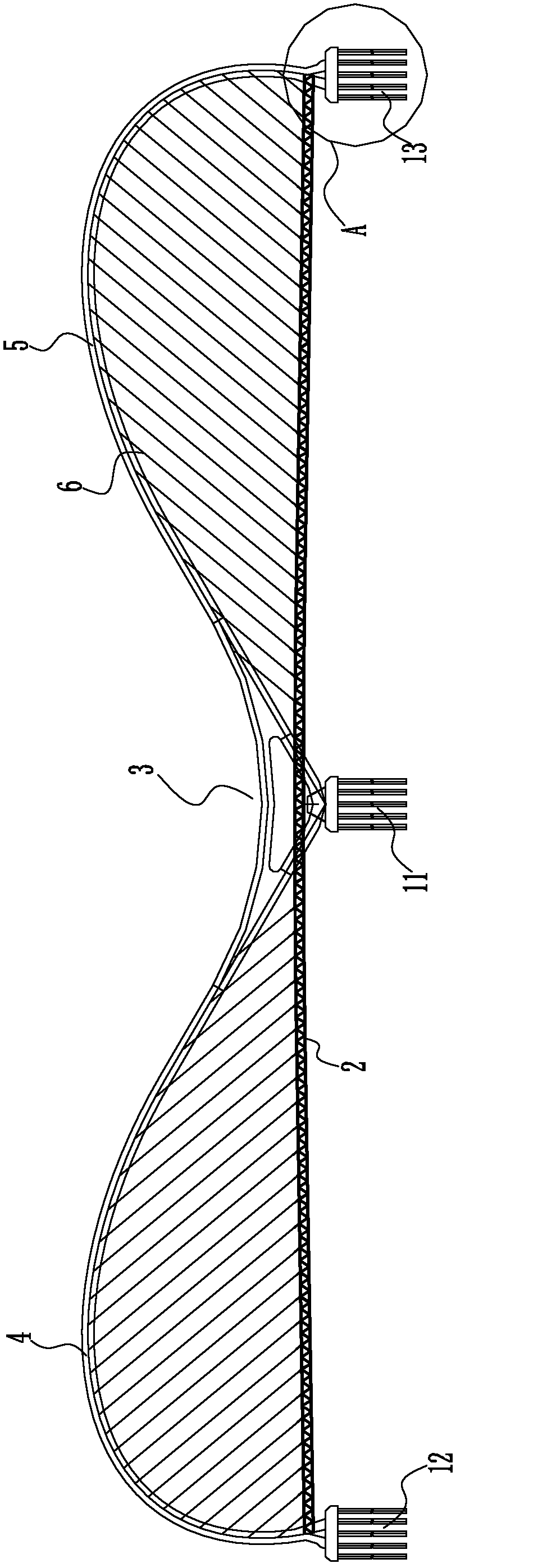

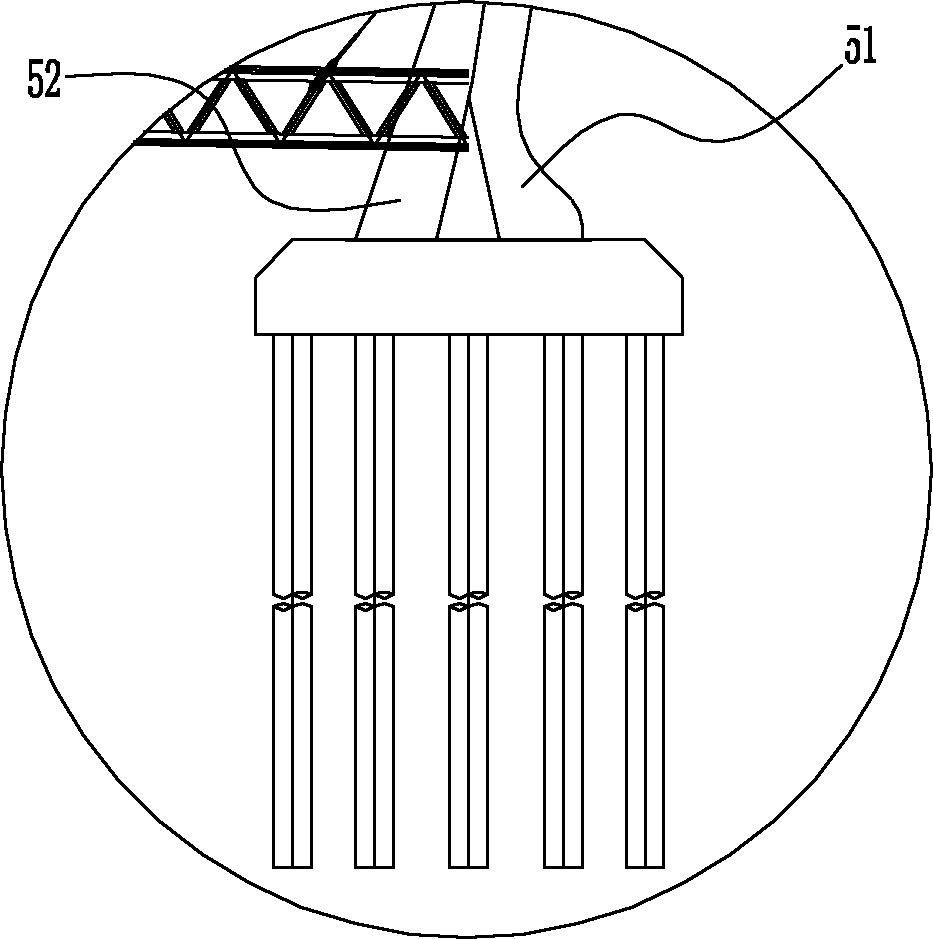

[0039] Such as figure 1 Shown, be a kind of long-span double-arch axis composite arch bridge of the present invention, it comprises girder 2, middle pier 11, and two auxiliary pier 12,13, middle pier 11 is as the middle fulcrum of whole composite arch bridge, two auxiliary pier 12 As the fulcrums at both ends, the middle pier 11 is fixedly equipped with an arch shaft combination 3, and an arch shaft curved beam 4, 5 is respectively connected between the middle pier 11 and the two auxiliary pier 12, and the arch shaft curved beams 4, 5 are arranged symmetrically. Both are in the shape of an upwardly protruding arc, and are formed by sequentially butting a plurality of arch axis curved beam segments.

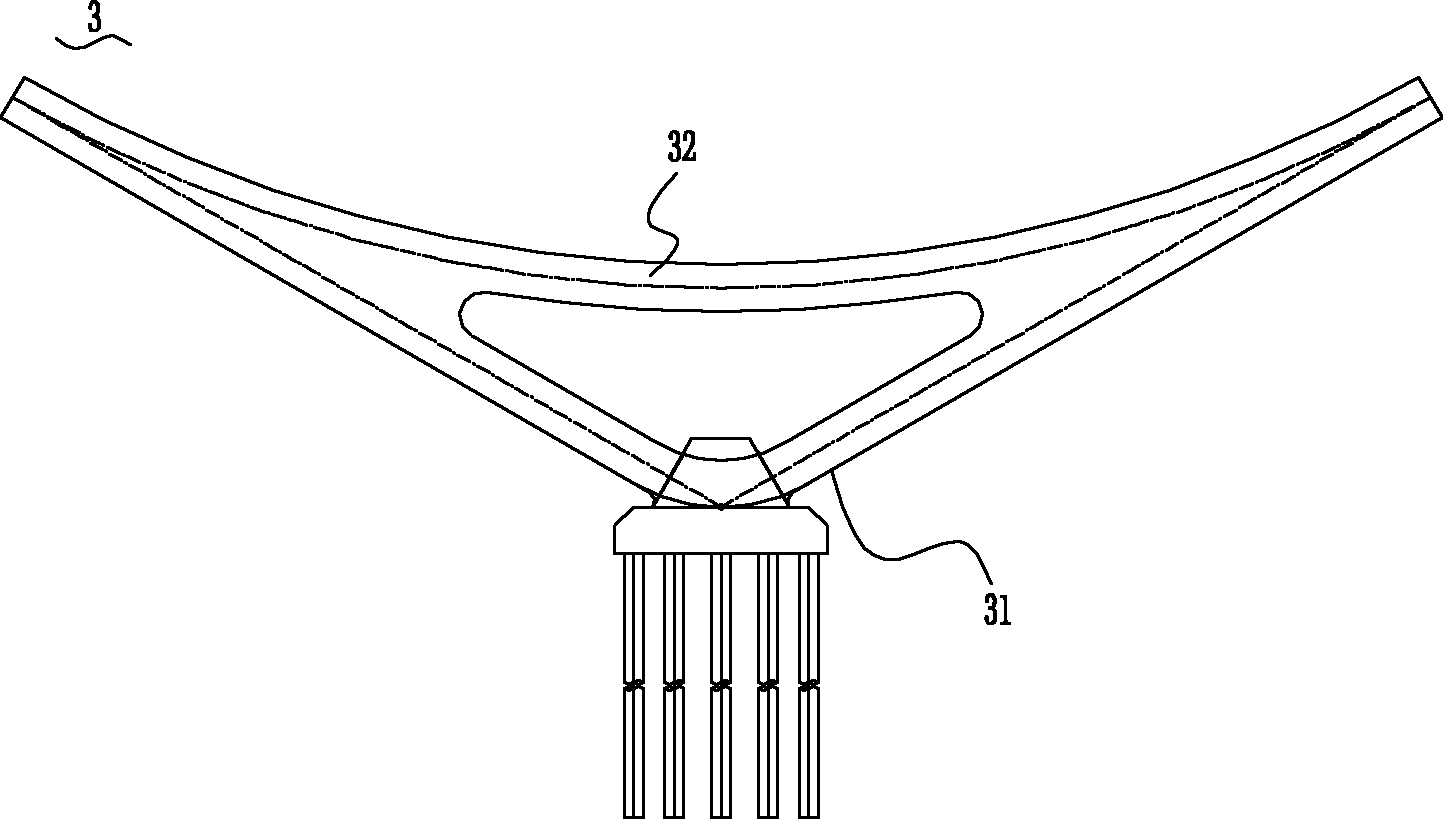

[0040] to combine figure 2 , 3 , the arch shaft combination 3 includes a lower arch shaft 31 and an upper arch shaft 32, the lower arch shaft 31 is in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com